Catalyst using TiO2-coated carbon nano tube composite material as carrier and preparation method thereof

A technology of composite materials and carbon nanotubes, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of flue gas and catalyst mass transfer process bottlenecks, etc., to achieve easy industrial production and high yield The effect of high and low activation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

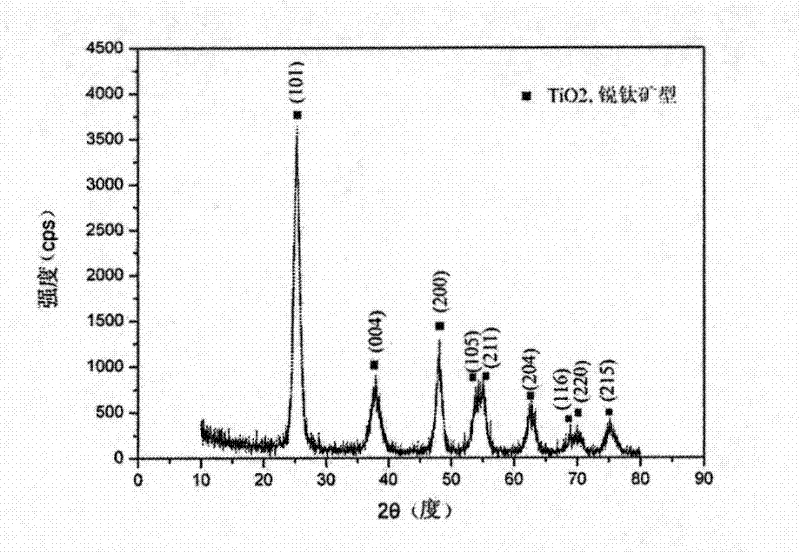

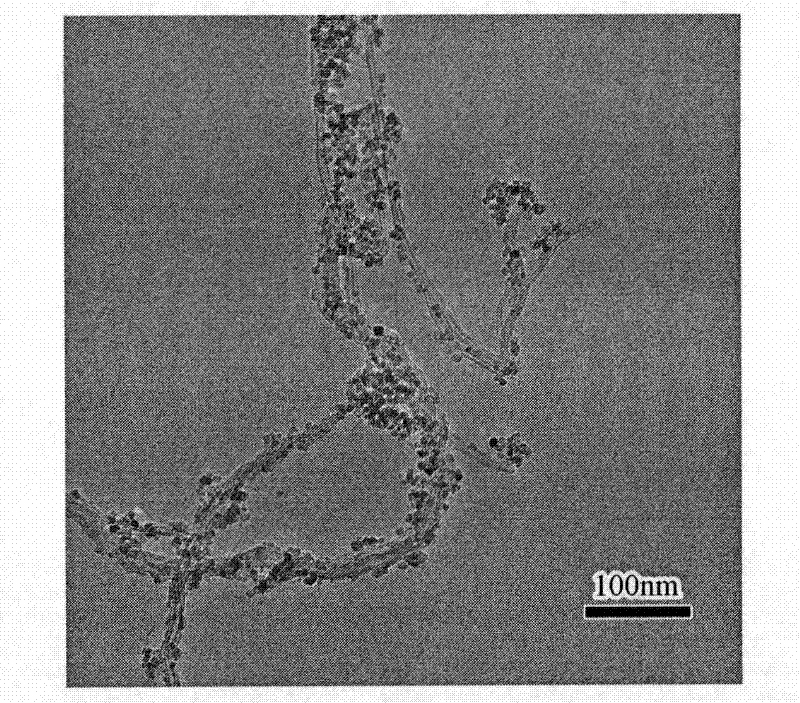

Embodiment 1

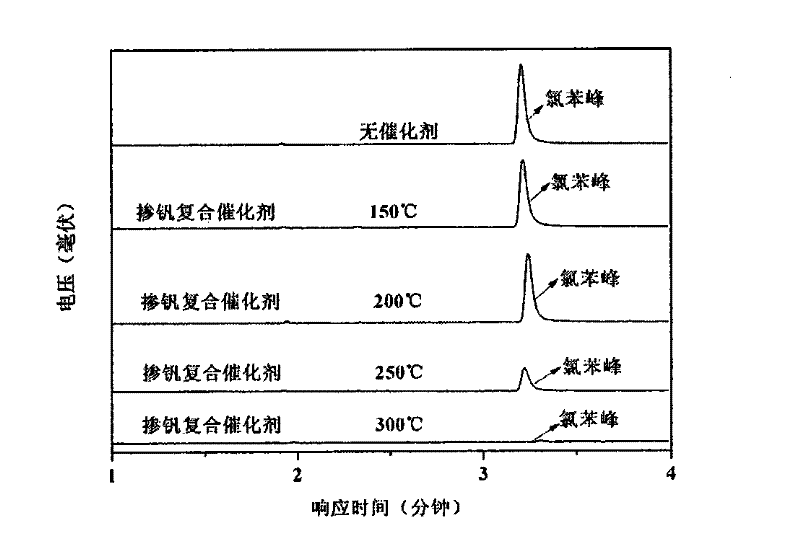

[0027] 3.4g of carbon nanotubes were ultrasonically dispersed in 700mL of absolute ethanol, and ultrasonically oscillated for 30 minutes to prepare liquid A; 170g of tetrabutyl titanate was dissolved in 700ml of absolute ethanol, and 30mL of The mass concentration is 10% ammonium metavanadate (NH 4 VO 3 ) of the oxalic acid solution, ultrasonic vibration for 30 minutes to obtain liquid B; under the condition of ultrasonic oscillation, slowly add liquid A to liquid B, and after ultrasonic oscillation for 30 minutes, place the mixed solution in a 2000mL sealed reaction kettle, and seal the reaction kettle. Insulate at 230°C for 2 hours; after cooling to room temperature, filter, wash the product with deionized water until neutral, and vacuum dry at 60°C to obtain a black powder catalyst. active ingredient V 2 o 5 The mass content in the catalyst is 5%.

[0028] The sample was reacted with simulated industrial waste gas components in a fixed-bed reactor, and its catalytic p...

Embodiment 2

[0030] 3.4g of carbon nanotubes were ultrasonically dispersed in 700mL of absolute ethanol, and ultrasonically oscillated for 30 minutes to prepare liquid A; 170g of tetrabutyl titanate was dissolved in 700ml of absolute ethanol, and 5.7 The mL mass concentration is 10% ammonium metavanadate (NH 4 VO 3 ) of the oxalic acid solution, ultrasonic vibration for 30 minutes to obtain liquid B; under the condition of ultrasonic oscillation, slowly add liquid A to liquid B, and after ultrasonic oscillation for 30 minutes, place the mixed solution in a 2000mL sealed reaction kettle, and seal the reaction kettle. Insulate at 230°C for 2 hours; after cooling to room temperature, filter, wash the product with deionized water until neutral, and vacuum-dry at 60°C to obtain a black powder catalyst. active ingredient V 2 o 5 The mass content in the catalyst is 1%.

Embodiment 3

[0032] 3. 4g of carbon nanotubes were ultrasonically dispersed in 700mL of absolute ethanol, and ultrasonically oscillated for 30 minutes to prepare liquid A; 170g of tetrabutyl titanate was dissolved in 700ml of absolute ethanol, and 100mL of The mass concentration is 14% ammonium metavanadate (NH 4 VO 3 ) of the oxalic acid solution, ultrasonic vibration for 30 minutes to obtain liquid B; under the condition of ultrasonic oscillation, slowly add liquid A to liquid B, and after ultrasonic oscillation for 30 minutes, place the mixed solution in a 2000mL sealed reaction kettle, and seal the reaction kettle. Insulate at 230°C for 2 hours; after cooling to room temperature, filter, wash the product with deionized water until neutral, and vacuum-dry at 60°C to obtain a black powder catalyst. active ingredient V 2 o 5 The mass content in the catalyst is 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com