Ag-AgCl conductive slurry capable of being screen-printed and preparation method thereof

A conductive paste, screen printing technology, applied in conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, material analysis by electromagnetic means, etc., can solve excessive addition, AgCl bulk crystal can not be obtained The problems of fine dispersion and less addition of AgCl dispersion can achieve the effect of reducing material waste, improving detection sensitivity, and improving dispersion state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

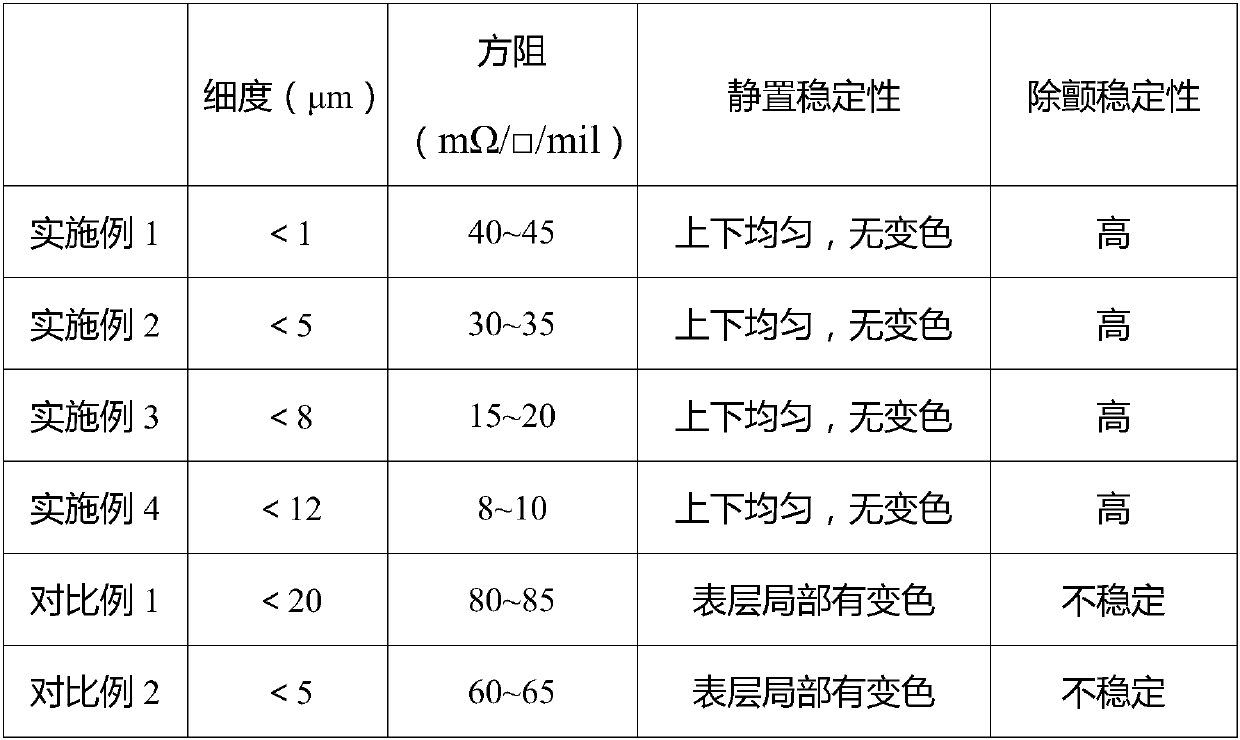

Examples

Embodiment 1

[0024] Step a: Preparation of Nano-AgCl Particles

[0025] 1 part of polyvinylpyrrolidone (hereinafter referred to as PVP) K90 powder was dissolved in 39 parts of deionized water as a mother solution, and the temperature of the mother solution was controlled at 15°C. Add 12 parts of 50wt% silver nitrate aqueous solution and 10 parts of 20wt% sodium chloride aqueous solution dropwise to mother liquor simultaneously with the speed of 2ml / min, stir and react for 30 minutes, obtain 62 parts of nano-AgCl dispersion liquids with an average particle diameter at 300nm.

[0026] Step b: Isolation of Nano-AgCl Particles

[0027] Add 31 parts of absolute ethanol to the AgCl dispersion prepared in step a, and place it in a water bath to keep the temperature at 60°C. Add 1 part of 30% oleic acid / ethanol solution and stir for 15 minutes. After static separation, the Ag / Cl particle precipitate was obtained by filtration.

[0028] Step c: AgCl carrier preparation

[0029] Add the precipit...

Embodiment 2

[0033] Step a: Preparation of Nano-AgCl Particles

[0034] Dissolve 2 parts of polyvinylpyrrolidone (hereinafter referred to as PVP) K90 powder in 38 parts of deionized water as a mother liquor, and control the temperature of the mother liquor to 15°C. Add 12 parts of 50wt% silver nitrate aqueous solution and 10 parts of 20wt% sodium chloride aqueous solution dropwise to mother liquor simultaneously with the speed of 2ml / min, stir and react for 30 minutes, obtain 62 parts of nano-AgCl dispersion liquids with an average particle diameter at 200nm.

[0035] Step b: Isolation of Nano-AgCl Particles

[0036] Add 31 parts of absolute ethanol to the AgCl dispersion prepared in step a, and place it in a water bath to keep the temperature at 60°C. Add 1 part of 30% oleic acid / ethanol solution and stir for 15 minutes. After static separation, the Ag / Cl particle precipitate was obtained by filtration.

[0037] Step c: AgCl carrier preparation

[0038]Add the precipitated AgCl partic...

Embodiment 3

[0042] Step a: Preparation of Nano-AgCl Particles

[0043] Dissolve 4 parts of polyvinylpyrrolidone (hereinafter referred to as PVP) K90 powder in 36 parts of deionized water as a mother liquor, and control the temperature of the mother liquor to 15°C. Add 12 parts of 50wt% silver nitrate aqueous solution and 10 parts of 20wt% sodium chloride aqueous solution dropwise to mother liquor simultaneously with the speed of 2ml / min, stir and react for 30 minutes, obtain 62 parts of nano-AgCl dispersion liquids with an average particle diameter at 120nm.

[0044] Step b: Isolation of Nano-AgCl Particles

[0045] Add 31 parts of absolute ethanol to the AgCl dispersion prepared in step a, and place it in a water bath to keep the temperature at 60°C. Add 1 part of 30% oleic acid / ethanol solution and stir for 15 minutes. After static separation, the Ag / Cl particle precipitate was obtained by filtration.

[0046] Step c: AgCl carrier preparation

[0047] Add the precipitated AgCl parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com