Pt nano particle-carbon nano tube composite material, preparation method and application thereof

A technology of carbon nanotubes and nanoparticles, applied in the field of nanomaterials, can solve the problems of the influence of electrocatalytic properties of composites and the difficulty of controlling Pt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

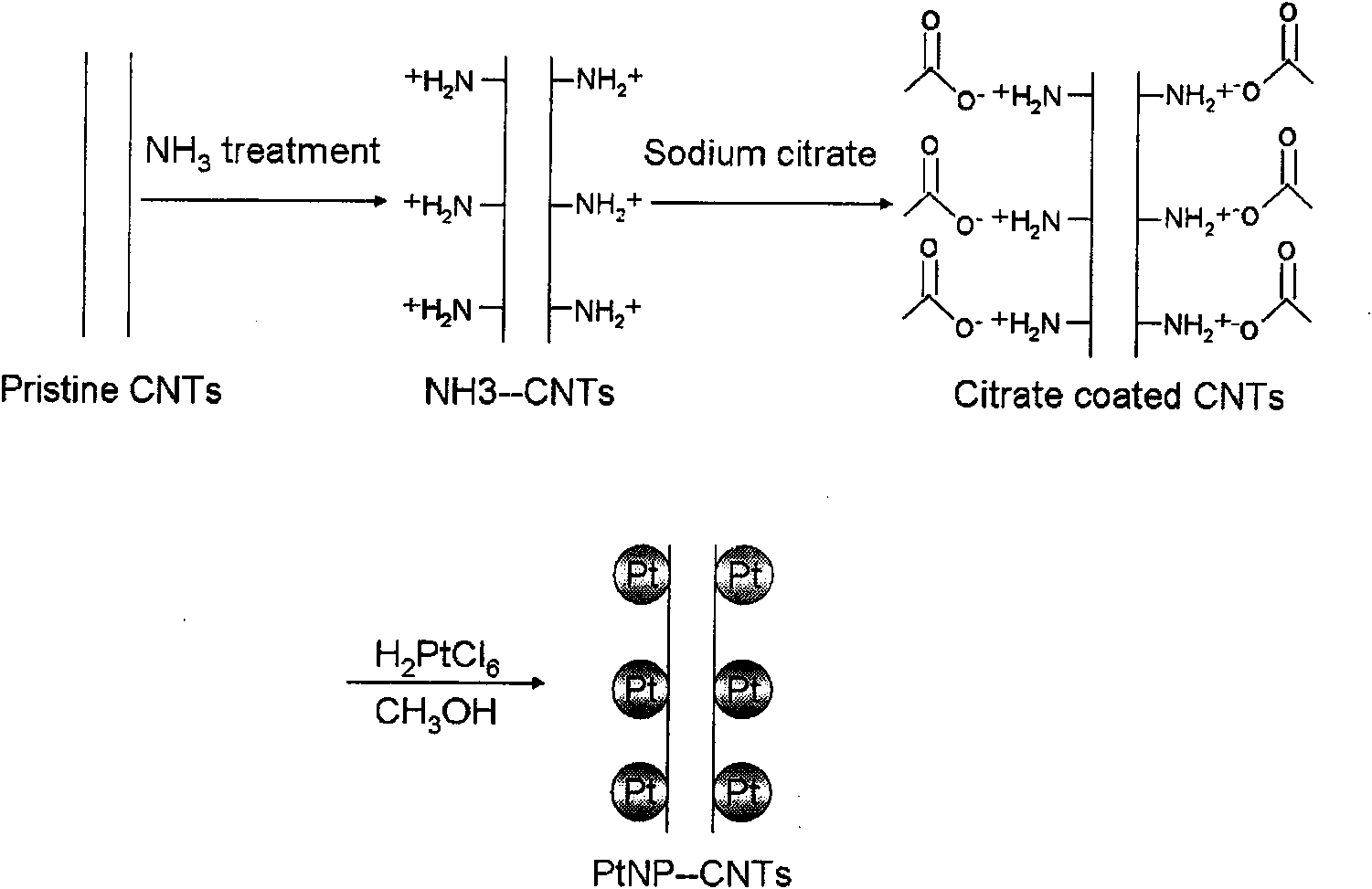

[0033] Pristine multi-walled carbon nanotubes (MWCNTs) placed in NH 3 Atmosphere (volume > 99%, 1l / min) tube furnace, heated at 600°C for 3 hours to obtain NH 3 High temperature pretreated MWCNTs (denoted as NH 3 -MWCNTs). Preparation of PtNP-NH 3 -MWCNT complex steps are as follows. First, different contents of NH 3 - The MWCNTs are submerged in an aqueous solution of sodium citrate, stirred after ultrasonication, filtered with suction, and dried to obtain MWCNTs covered with sodium citrate. Then 10ml 2mM H 2 PtCl 6 and 90ml CH 3 The OH mixture was mixed with the above-mentioned MWCNTs covered with sodium citrate and condensed and refluxed in an oil bath at 80 °C for 90 min to obtain PtNP-NH 3 -MWCNT.

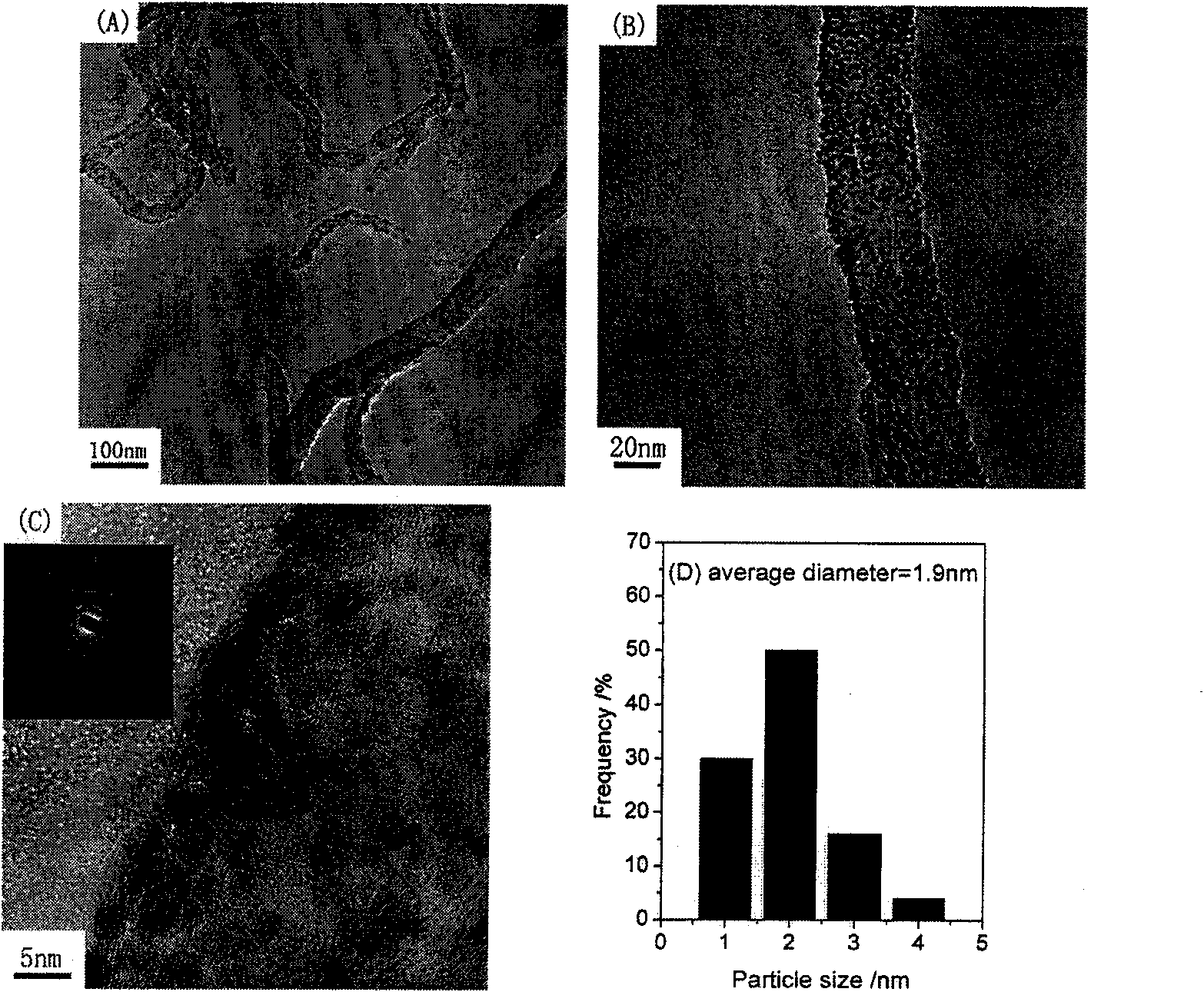

[0034] from figure 2 (A, B) It can be seen that PtNPs are uniformly wrapped on the surface of MWCNTs, and hardly any agglomeration of Pt particles is found. Pt-NH can be measured from EDS 3 - The Pt content in MWCNTs is 26 wt%, which is very close to the original ...

Embodiment 2

[0037] Pristine multi-walled carbon nanoparticles (MWCNTs) placed in NH 3 Atmosphere (volume > 99%, 1l / min) tube furnace, heated at 600°C for 3 hours to obtain NH 3 High temperature pretreated MWCNTs. Preparation of PtNP-NH 3 -MWCNT complex steps are as follows. First, 0.01 g of NH 3 - The MWCNTs were submerged in 50ml of 3mM sodium citrate aqueous solution, stirred after ultrasonication, suction filtered, and dried to obtain MWCNTs covered with sodium citrate. Then 10ml 1mM H 2 PtCl 6 and CH 3 The mixture of OH (methanol volume content is 4%) and the above-mentioned MWCNTs covered with sodium citrate were mixed and condensed and refluxed in an oil bath at 80° C. for 90 min to obtain PtNP-MWCNTs. Prepared PtNP-NH 3 -TEM photos of MWCNT composites as Figure 4 shown. PtNPs uniformly cover the outer wall of MWCNTs, and its particle size is about 10 nm.

Embodiment 3

[0039] The acid-treated single-walled carbon nanometers (SWCNTs) were placed in NH 3 Atmosphere (volume > 99%, 1l / min) tube furnace, heated at 1000°C for 2 hours to obtain NH 3 High temperature pretreated SWCNTs (denoted as NH 3 -SWCNTs). Preparation of PtNP-NH 3 -SWCNT complex steps are as follows. First, the NH 3 - The SWCNTs are submerged in an aqueous solution of sodium citrate, stirred after ultrasonication, filtered with suction, and dried to obtain SWCNTs covered with sodium citrate. Then 10ml 2mM H 2 PtCl 6 and 90ml CH 3 The OH mixture was mixed with the above SWCNTs covered with sodium citrate, condensed and refluxed in an oil bath at 80 °C for 90 min to obtain PtNP-NH 3 -SWCNT. Prepared PtNP-NH 3 -TEM photos of SWCNT composites as Figure 5 shown. PtNPs uniformly cover the outer walls of SWCNTs, and their particle size distribution is 2–4 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com