Preparation method for manganese dioxide hollow sphere

A manganese dioxide and hollow sphere technology is applied in the field of materials, which can solve the problems of affecting performance, cumbersome process, structural damage, etc., and achieve the effects of low production cost, simple process steps and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Taking 0.5mmol of the raw material manganese sulfate used for preparing manganese dioxide hollow spheres as an example, other raw materials used and their proportioning and preparation methods are as follows:

[0041] 1. Weigh 0.0845g manganese sulfate, 0.474g potassium permanganate, 0.054g FeCl 3 ·6H 2 O, join in the hydrothermal reaction kettle, add 14mL deionized water and fully stir to make manganese sulfate, potassium permanganate and FeCl 3 ·6H 2 O dissolved, then add 1ml of sulfuric acid, that is manganese sulfate and potassium permanganate, FeCl 3 ·6H 2 O, the molar ratio of sulfuric acid is 1: 6: 0.4: 36.8. The manganese sulfate and sulfuric acid used were of analytical grade.

[0042] 2. Put the hydrothermal reaction kettle in an oven at a constant temperature of 150°C for hydrothermal reaction for 20 minutes, and naturally cool to room temperature.

[0043] 3. The product obtained in step 2 was washed with deionized water for 5 times, and dried in an ov...

Embodiment 2

[0046] Taking 0.5mmol of the raw material manganese sulfate used for preparing manganese dioxide hollow spheres as an example, other raw materials used and their proportioning and preparation methods are as follows:

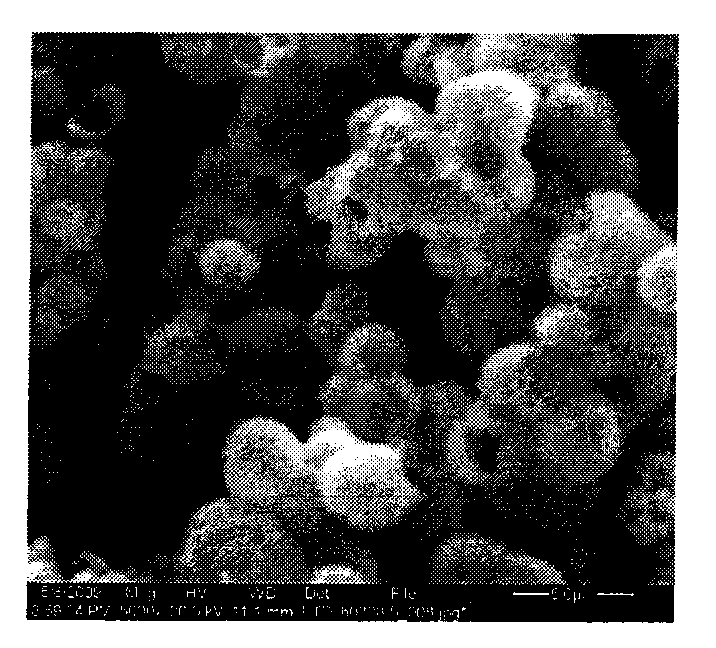

[0047] In step 1, weigh 0.0845g manganese sulfate, 0.474g potassium permanganate, 0.0054g FeCl 3 ·6H 2 O was added to the hydrothermal reaction kettle, and 14 mL of deionized water was added and stirred fully to make manganese sulfate, potassium permanganate and FeCl 3 ·6H 2 O dissolved, then add 1ml of sulfuric acid, that is manganese sulfate and potassium permanganate, FeCl 3 ·6H 2 O, the molar ratio of sulfuric acid is 1: 6: 0.04: 36.8. The other steps are the same as in Example 1, and manganese dioxide hollow spheres are prepared. The morphology of the prepared manganese dioxide hollow spheres was observed with a scanning electron microscope, and the scanning electron microscope photos are shown in Figure 5 . Depend on Figure 5 It can be seen that i...

Embodiment 3

[0049] Taking 0.5mmol of the raw material manganese sulfate used for preparing manganese dioxide hollow spheres as an example, other raw materials used and their proportioning and preparation methods are as follows:

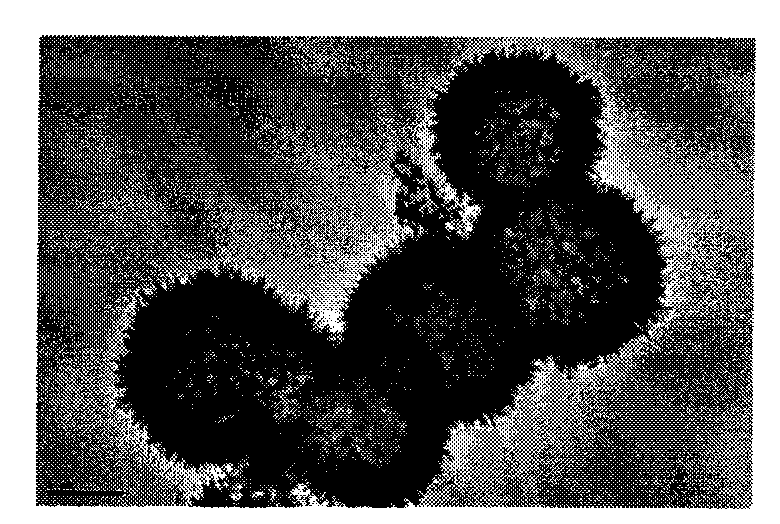

[0050] In step 1, weigh 0.0845g manganese sulfate, 0.474g potassium permanganate, 0.135g FeCl 3 ·6H 2 O was added to the hydrothermal reaction kettle, and 14 mL of deionized water was added and stirred fully to make manganese sulfate, potassium permanganate and FeCl 3 ·6H 2 O dissolved, then add 1ml of sulfuric acid, that is manganese sulfate and potassium permanganate, FeCl 3 ·6H 2 O, the molar ratio of sulfuric acid is 1: 6: 1: 36.8. The other steps are the same as in Example 1, and manganese dioxide hollow spheres are prepared. The morphology of the prepared manganese dioxide hollow spheres was observed with a scanning electron microscope, and the scanning electron microscope photos are shown in Image 6 . Image 6 It can be seen that when the amount of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com