Device and method for operating multiple adherent cells on same substrate

A substrate and cell technology, applied in tissue cell/virus culture devices, biochemical equipment and methods, biochemical instruments, etc., can solve the problems of reducing the stability of the method, difficult to realize, unstable properties of block copolymers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] 1) Evaporate a 5nm titanium adhesion layer on the surface of a clean glass slide (thickness 0.15mm), and then vapor-deposit a 30nm thick gold layer on it to obtain a substrate required for an experiment;

[0074] 2) Cut the base of step 1) into 2×2cm 2 small pieces, spare;

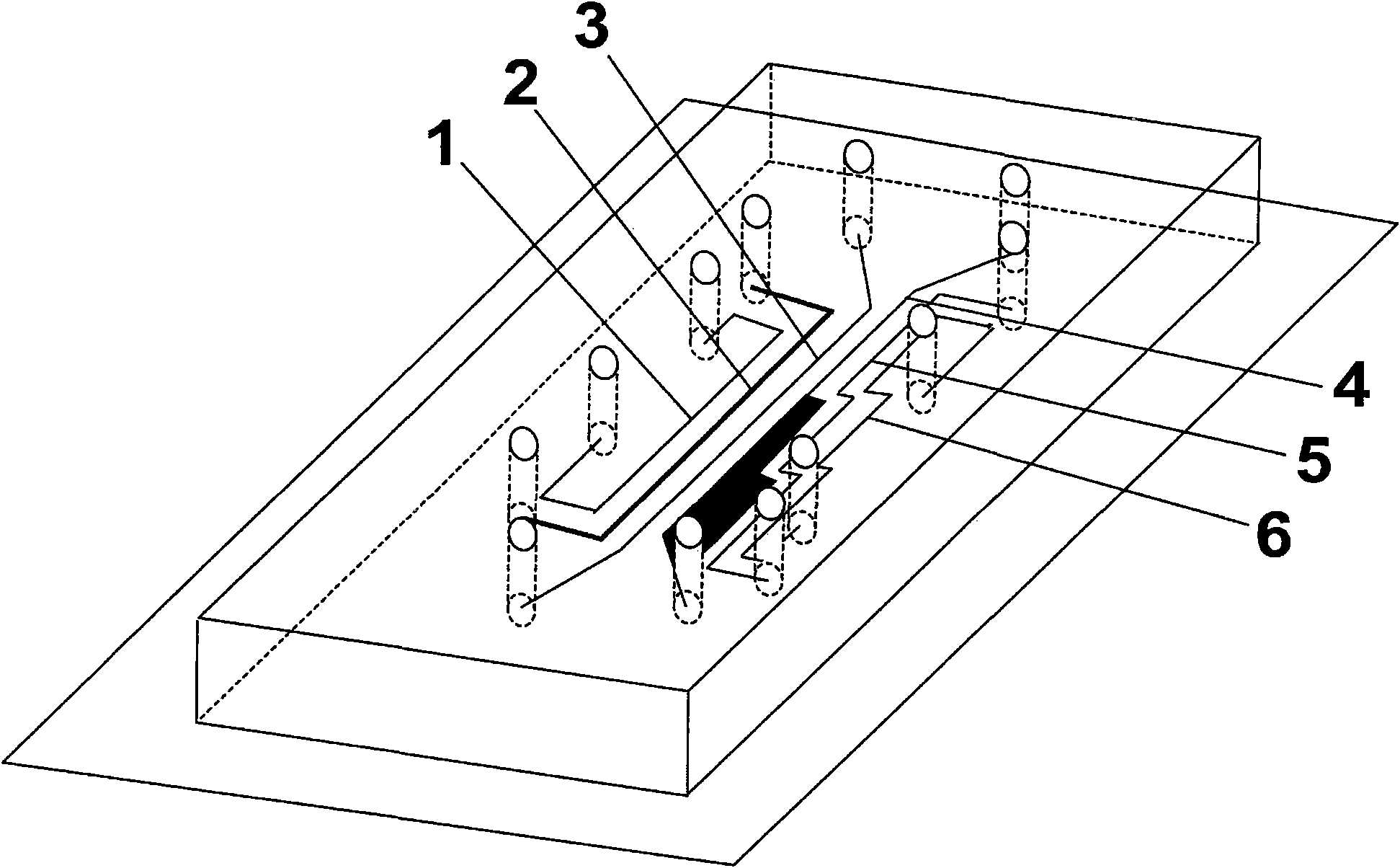

[0075] 3) Use photolithography to prepare at least one group of convex linear micro-units on a silicon wafer. First, use the graphics software L-edit to design six side-by-side convex strips of the desired pattern. Among them, the three convex strips on the right The strip is a convex strip of equal cross-section, the middle sections of the three convex strips on the right side are parallel to each other, and the two end sections other than the middle section of the first convex strip on the right are perpendicular to the two ends of the middle section of the convex strip. Fold to the right 0.7cm, and then vertically fold to the middle 0.4cm; the two ends of the second convex strip on the right sid...

Embodiment 2

[0088]1) vapor-deposit 10nm of chromium on the surface of a clean glass slide (thickness 0.12mm) as an adhesion layer, and then vapor-deposit a 50nm-thick gold layer on it to obtain a substrate required for an experiment;

[0089] 2) Cut the base of step 1) into 2×2cm 2 small pieces, spare;

[0090] 3) Prepare at least one group of convex line microstructure units on the silicon wafer using photolithography technology, first use the graphics software L-edit to design six side-by-side convex lines of the desired pattern, the six side-by-side convex lines include : There are a total of six convex lines from left to right; the three convex lines on the right are parallel in the middle, and the first convex line on the right is folded vertically to the right by 0.5cm at both ends of the parallel section, and then folded vertically 0.3cm to the middle; the second convex line on the right is vertically folded to the right at both ends of the parallel section by 0.8cm; the third con...

Embodiment 3

[0097] 1) Evaporate 2nm of titanium on the surface of a clean glass slide (thickness 0.15mm) as an adhesion layer, and then vapor-deposit a 20nm thick gold layer on it to obtain a substrate required for an experiment;

[0098] 2) Cut the base of step 1) into 2×2cm 2 small pieces, spare;

[0099] 3) Prepare at least one group of convex line microstructure units on the silicon wafer using photolithography technology, first use the graphics software L-edit to design six side-by-side convex lines of the desired pattern, the six side-by-side convex lines include : A total of six convex lines from left to right; the three convex lines on the right are parallel in the middle, and the first convex line on the right is folded vertically to the right by 0.8cm at both ends of the parallel section, and then folded vertically 0.5cm to the middle; the second convex line on the right is vertically folded to the right at both ends of the parallel section by 1.5cm; the third convex line on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com