SludgeDewatering equipment and sludge dewatering process

A technology for sludge dewatering and equipment, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of high energy consumption, low dewatering efficiency, low dewatering rate, etc. The effect of increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

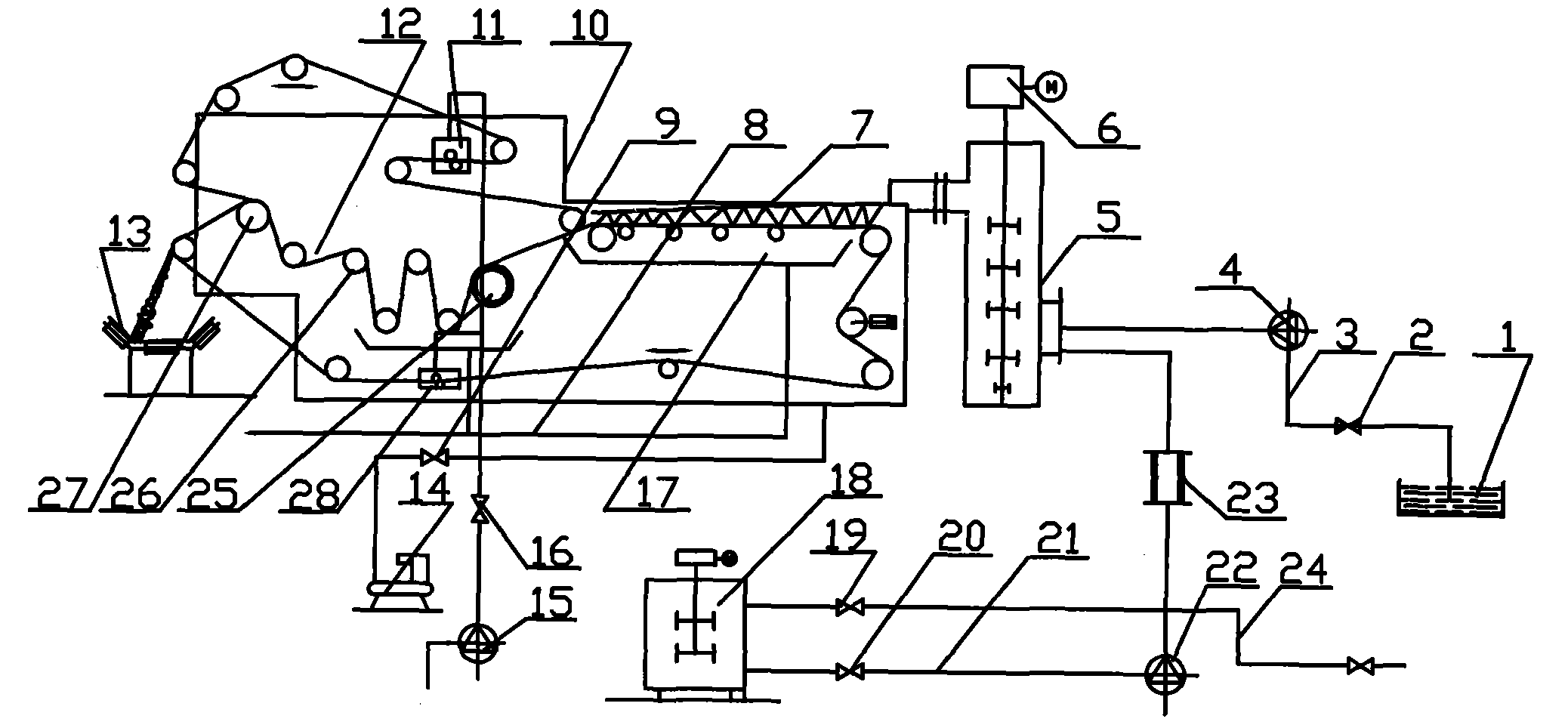

[0009] Embodiment 1: with reference to attached figure 1 . Sludge dehydration equipment, which includes an electrical controller and an automatic deviation correction device, the inlet of the sludge pump 4 is connected to the sludge tank 1 through the pipe 3 and the valve 2, the outlet of the sludge pump 4 is connected to the inlet of the flocculation mixer 5, and the medicine mixer The inlet of 18 enters water through pipeline 24 and valve 19, the outlet of drug mixer 18 communicates with the inlet of metering pump 22 through pipeline 21 and valve 20, the outlet of metering pump 22 communicates with the inlet of flocculation agitator 5 through flowmeter 23, and flocculation agitator 5 is connected by The motor 6 drives the stirring, and the outlet of the flocculation agitator 5 is directly facing the filter cloth clip dehydration device 7 in the filter cloth conveying mechanism. The outlet of the device 7 directly inputs the pre-dewatered mud into the wedge-shaped dewatering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com