Method for preparing nontoxic zirconium octoate

A technology of zirconium isooctanoate and isooctanoic acid, which is applied in the field of producing non-toxic zirconium isooctanoate, can solve the problems of few research reports and no recycling of precious metal zirconium, and achieve a mature and reliable method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

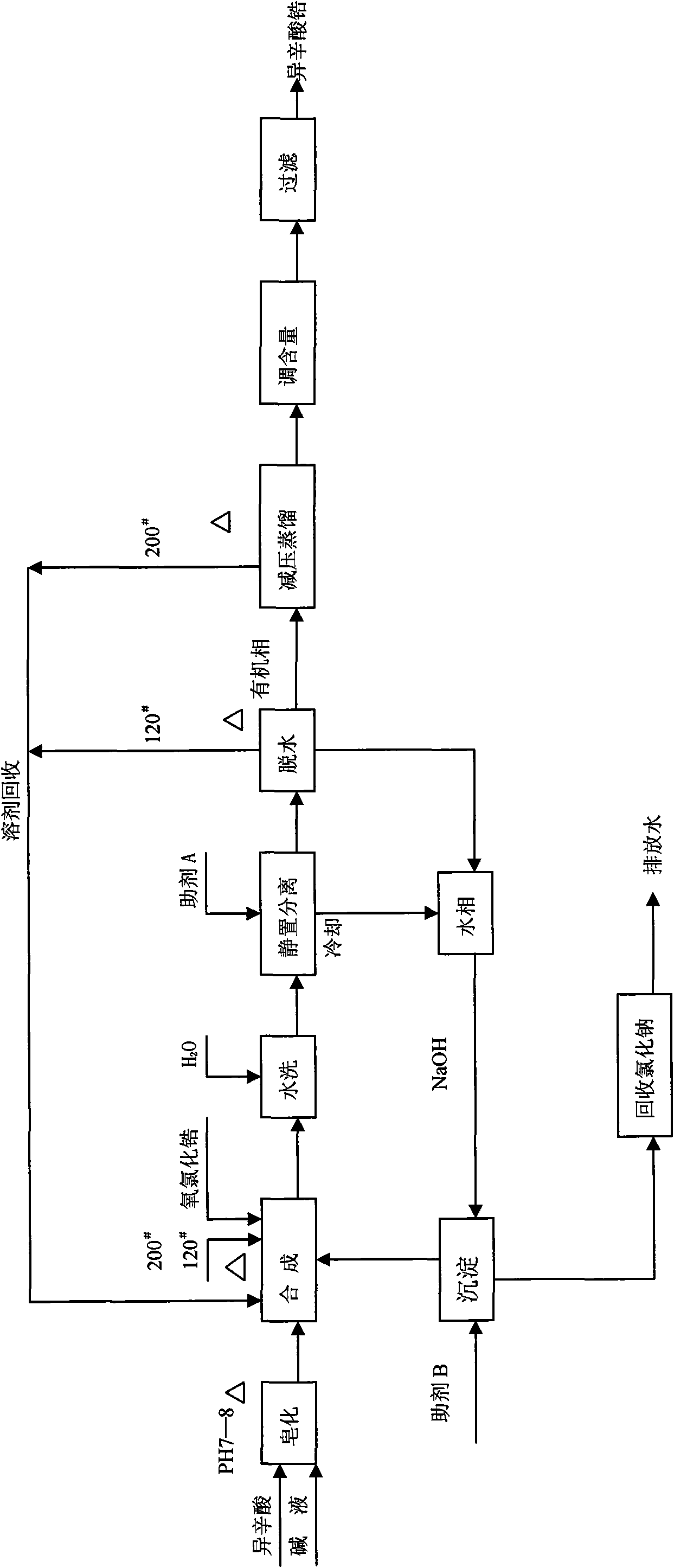

[0031] Example 1: first put isooctanoic acid (RCOOH) into the saponification tank, then mix 30% NaOH and isooctanoic acid (RCOOH) to PH7, heat to 70°C and carry out saponification reaction for 40 minutes; then saponification liquid enters the synthesis reaction , add saponification solution 10% zirconium oxychloride and saponification solution 10% 200 # , saponification solution 5% 120 # Solvent, heat up to 90°C, stir, 40min; wash twice with water after synthesis reaction, add P350 extractant [di-(1-methylheptyl methylphosphonate)] and P204 extractant di-(2-ethylhexanoic acid) ) mixed extractant, mixing ratio: 0.8:0.2 standing for separation; the organic phase after separation and dehydration was subjected to vacuum distillation at 180° C.; 50 min; the zirconium metal content was adjusted and filtered to obtain the finished zirconium isooctanoate.

Embodiment 2

[0032] Example 2: First put isooctanoic acid (RCOOH) into the saponification tank, then mix 30% NaOH and isooctanoic acid (RCOOH) to pH 7.5, heat to 75°C for saponification for 40 minutes; then put the saponification solution into Synthesis reaction, add 10% zirconium oxychloride of saponification liquid and 200% of saponification liquid 10% in synthesis reaction # , saponification solution 5% 120 # Solvent, heat up to 93°C, stir, 40min; wash twice with water after synthesis reaction, add P350 extractant [di-(1-methylheptyl methylphosphonate)] and P204 extractant di-(2-ethylhexanoic acid) ) mixed extractant, mixing ratio: 0.8:0.2 standing for separation; the organic phase after separation and dehydration was subjected to vacuum distillation at 190° C.; 55 minutes; zirconium metal content was adjusted and filtered to obtain the finished zirconium isooctanoate.

Embodiment 3

[0033] Example 3: first put isooctanoic acid (RCOOH) into the saponification tank, then mix 30% concentration of NaOH and isooctanoic acid (RCOOH) to PH8, heat to 80°C and carry out saponification reaction for 40min; then saponification liquid enters the synthesis reaction , add saponification solution 10% zirconium oxychloride and saponification solution 10% 200 # , saponification solution 5% 120 # Solvent, heat up to 95°C, stir, 40min; wash twice with water after synthesis reaction, add P350 extractant [di-(1-methylheptyl methylphosphonate)] and P204 extractant di-(2-ethylhexanoic acid) ) mixed extractant, mixing ratio: 0.8:0.2 standing for separation; the organic phase after separation and dehydration was subjected to vacuum distillation at 200° C.; 60 min; zirconium metal content was adjusted and filtered to obtain the finished zirconium isooctanoate.

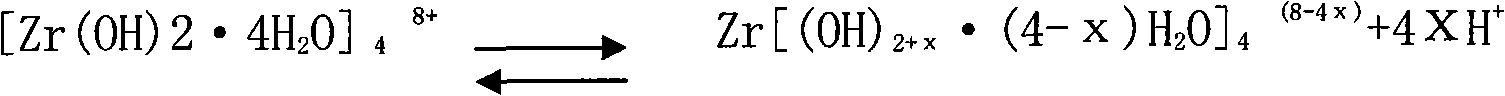

[0034] Saponification, according to the requirements of the present invention for the optimal yield to material ratio; h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com