Method for separating and preparing hydrogen by decomposing water in fuel cell through photocatalysis

A fuel cell, water splitting technology, used in fuel cells, electrolysis processes, electrolysis components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

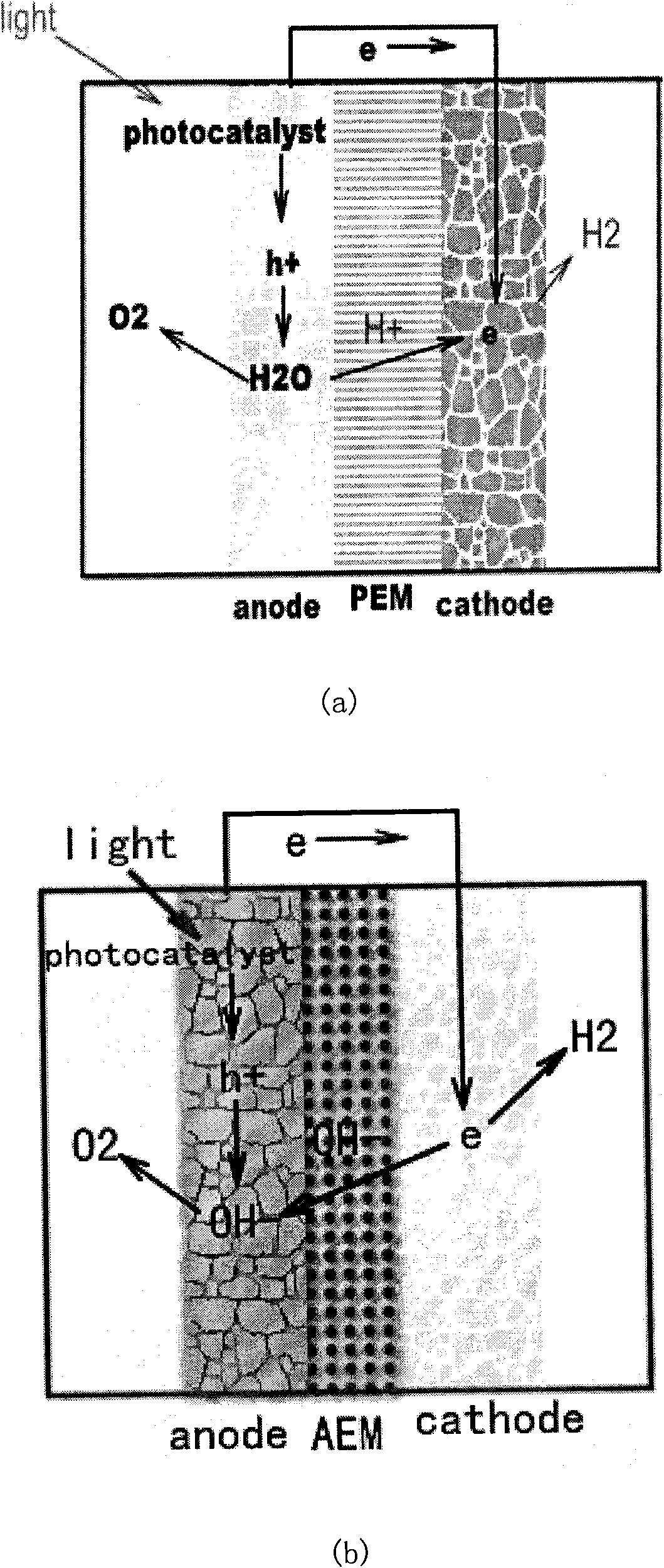

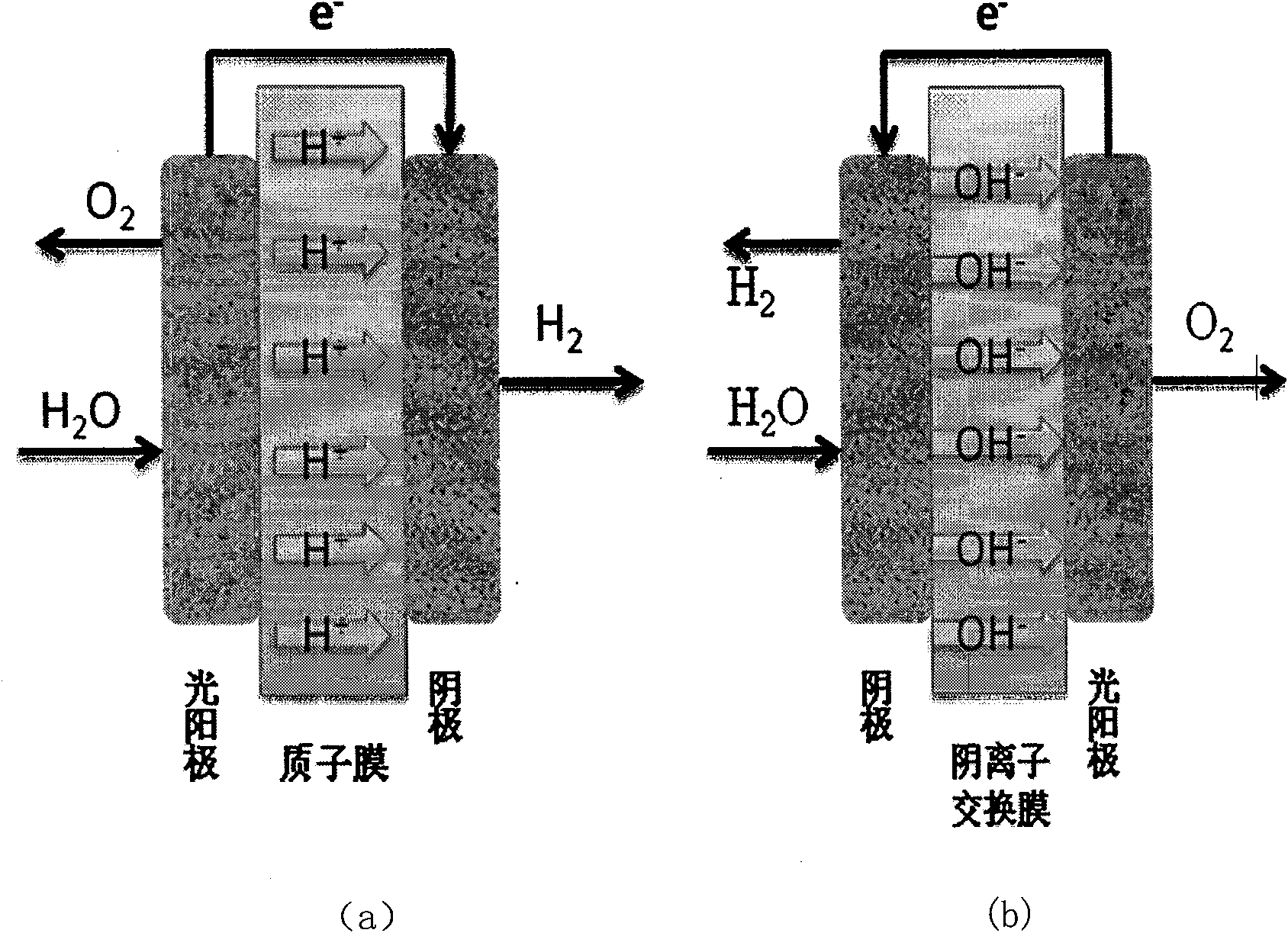

AI Technical Summary

Problems solved by technology

Method used

Image

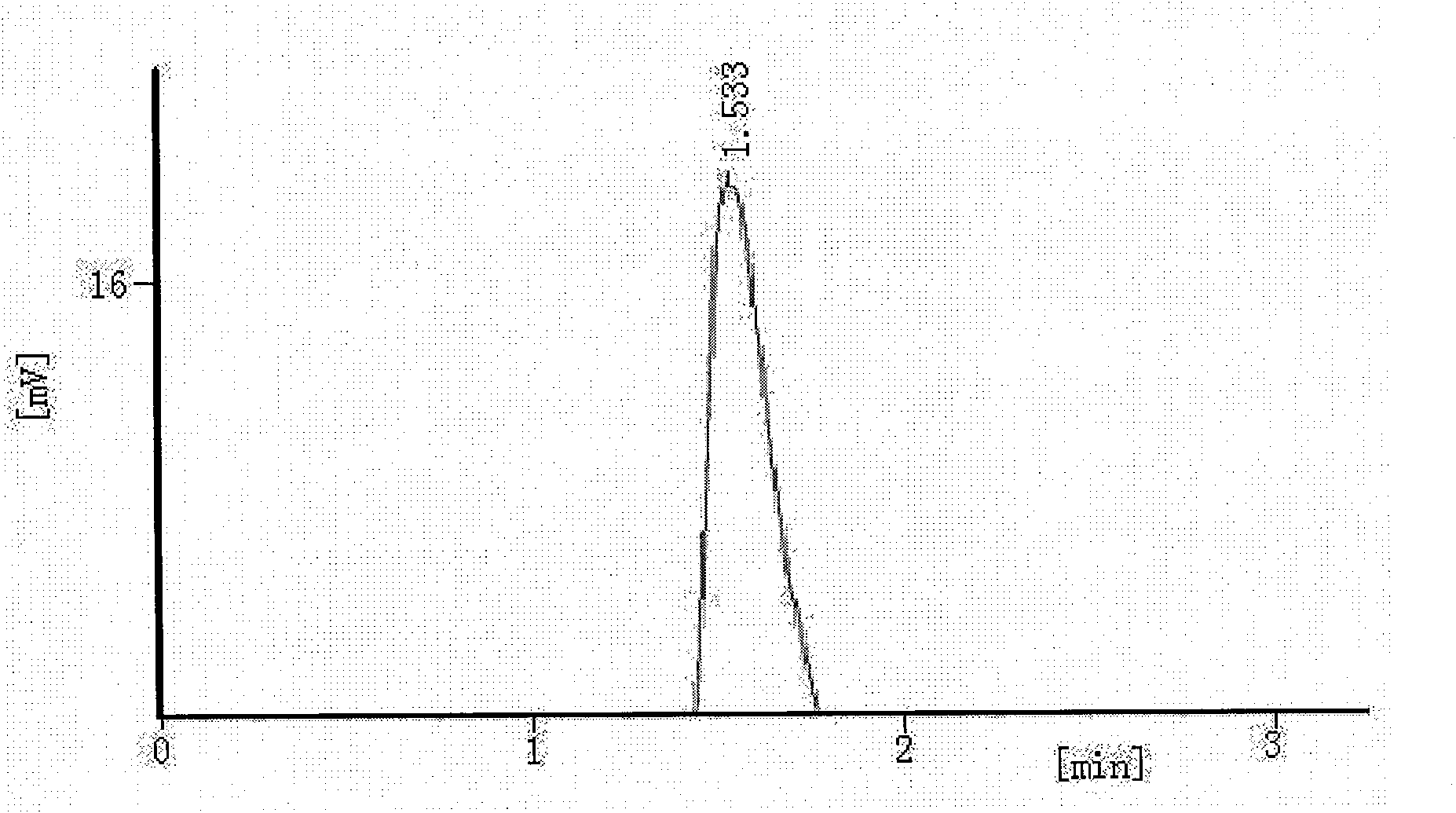

Examples

Embodiment 1

[0031] 1. Preparation of photoanode

[0032] 3g homemade visible light catalyst (such as: InVO 4 、MBi 2 o 4 (M=Mg, Ca, Sr, Ba), Bi 2 WO 6 ) into the mortar, then add 1ml of 10% acetylacetone in absolute ethanol, grind for 30min; then add 4.5ml of water, 0.1mlTriton X-100 and 30%wt (0.9g) polyethylene glycol (molecular weight 20000) The mixed solution was ground for 30 minutes, and the appropriate concentration was adjusted, and the coating method was used to draw two layers of TiO 2 A visible photocatalyst film was prepared on the FTO glass conductive surface of the film. Use scotch tape (about 40 μm thick) to stick longitudinally on both sides of the FTO conductive glass (6×8cm) that has been drawn, add a certain amount of visible light catalyst slurry prepared by the method described above, and roll coat it with a glass rod to form a film. The film forming effect is the best in one direction, and the film area is about 5×6cm 2 . The thin film electrode was placed in ...

Embodiment 2

[0044] 1. Preparation of photoanode

[0045] 3g homemade TiO 2 Nanomaterials are put into mortar, then add 1ml 10% acetylacetone absolute ethanol solution, grind 30min; Then add 4.5ml water, 0.1mlTriton X-100 and 30%wt (0.9g) polyethylene glycol (molecular weight 20000 ) mixed solution, grind for 30 minutes, adjust the appropriate concentration, and use the coating method to draw two layers of TiO 2 Preparation of TiO on the FTO Glass Conductive Surface of Thin Films 2 film. Use scotch tape (about 40 μm thick) to stick longitudinally on both sides of the FTO conductive glass (6×8cm) that has been drawn, and add a certain amount of TiO prepared by the method described above. 2 Slurry, roll coating with a glass rod to form a film, the best film forming effect in the same direction, the film area is about 5×6cm 2 . The thin film electrode was placed in a muffle furnace, heat treated at 500°C for one hour, and cooled naturally to 80°C for later use.

[0046] 2. Preparation o...

Embodiment 3

[0057] 1. Preparation of photoanode

[0058] 3g homemade TiO 2 Nanomaterials are put into mortar, then add 1ml 10% acetylacetone absolute ethanol solution, grind 30min; Then add 4.5ml water, 0.1mlTriton X-100 and 30%wt (0.9g) polyethylene glycol (molecular weight 20000 ) mixed solution, grind for 30 minutes, adjust the appropriate concentration, and use the coating method to draw two layers of TiO 2 Preparation of TiO on the FTO Glass Conductive Surface of Thin Films 2 film. Use scotch tape (about 40 μm thick) to stick longitudinally on both sides of the FTO conductive glass (6×8cm) that has been drawn, and add a certain amount of TiO prepared by the method described above. 2 Slurry, roll coating with a glass rod to form a film, the best film forming effect in the same direction, the film area is about 5×6cm 2 . The thin film electrode was placed in a muffle furnace, heat treated at 500°C for one hour, and cooled naturally to 80°C for later use.

[0059] 2. Preparation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com