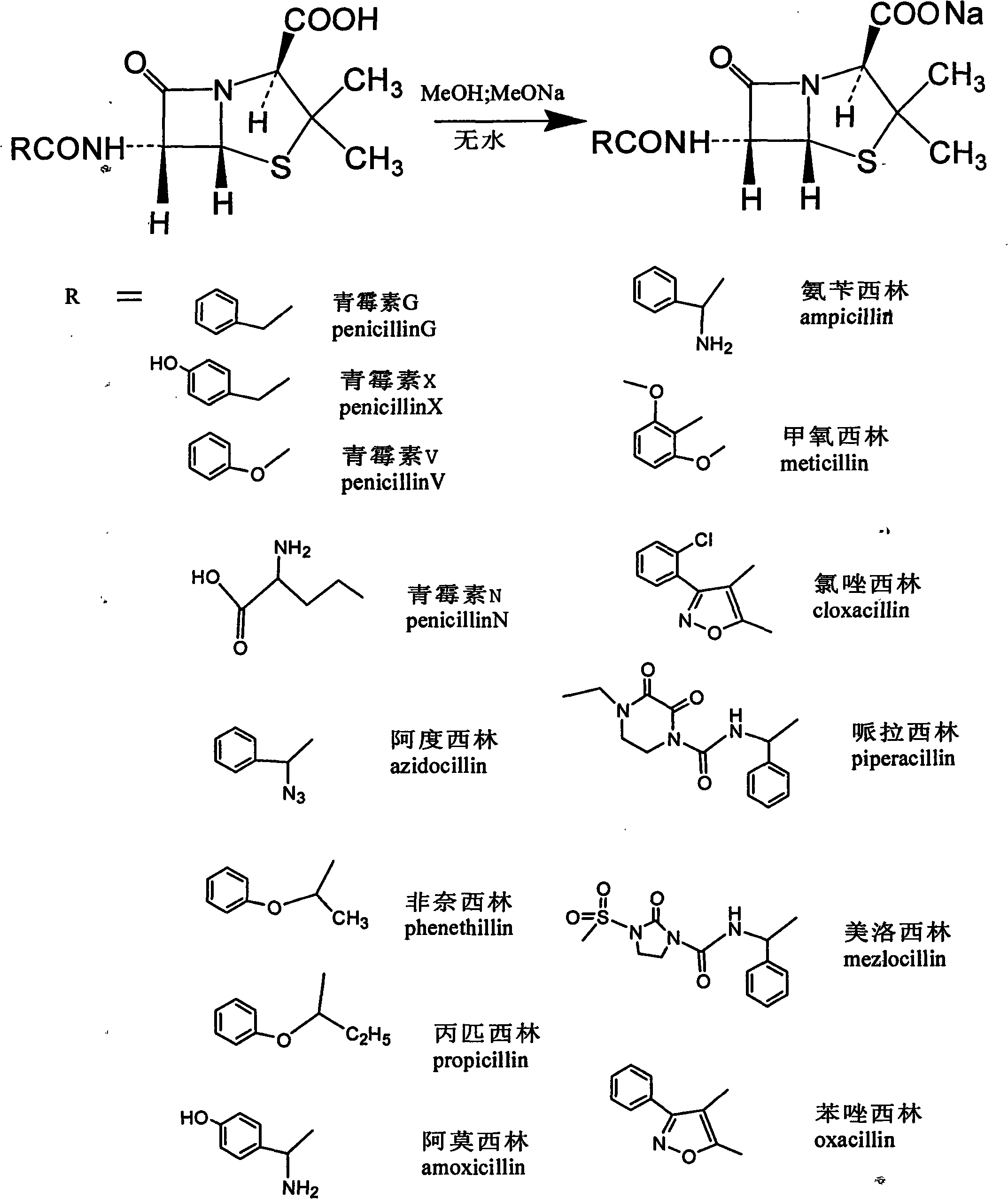

Method for synthesizing penicillin sodium salt and potassium salt

A synthetic method and technology of penicillin sodium, applied in organic chemistry, antibacterial drugs, etc., can solve the problems of allergic reactions and high levels of related substances in the body, and achieve the effect of safe oral absorption, strong curative effect, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

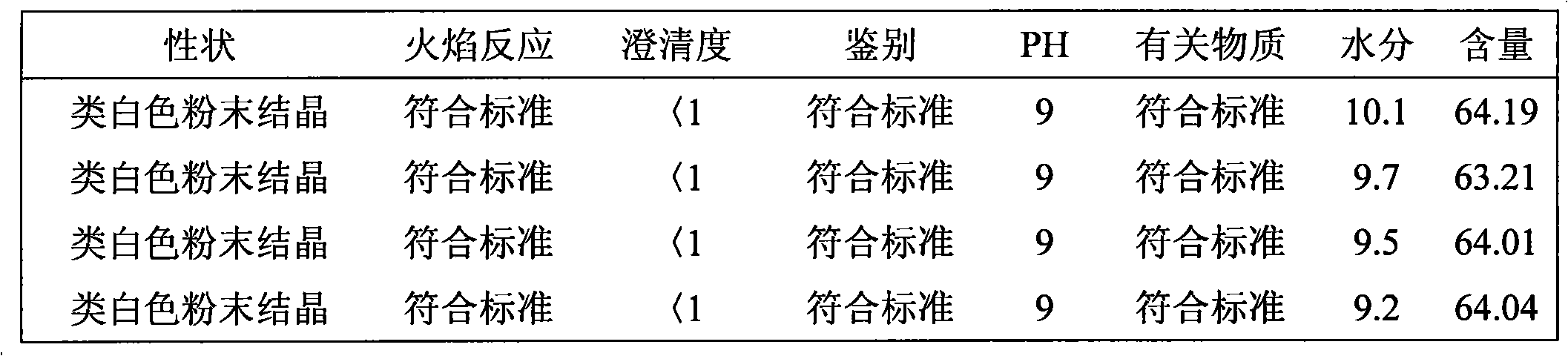

Embodiment 1

[0060] A kind of synthetic method of penicillin sodium salt, is to take the dried amoxicillin trihydrate 3.0g, join in the three-necked bottle, then add anhydrous methanol 20ml and anhydrous triethylamine 1.0ml in the three-necked bottle , after fully stirring to make it dissolve, place the three-necked flask in an ice bath, and when the temperature drops to 0°C, slowly add 3ml of methanol solution of sodium methoxide dropwise (concentration is 0.1mol / L) with a dropper to adjust The pH value is 9-10, the dropping time is 5 minutes, and the methanol solution of sodium methoxide is added dropwise and reacted for 20 minutes under stirring. Then the prepared above-mentioned reaction solution is added to a rotary evaporator, the temperature of the water-soluble pot is 40° C., and the pressure is 0.09 MPa. After the rotary evaporator drains the solvent, amoxicillin sodium crystallizes out, and the obtained wet amoxicillin The sodium is sent to a vacuum drying oven at 40° C. under a ...

Embodiment 2

[0062] A kind of synthetic method of penicillin sodium salt, is to get the dried amoxicillin trihydrate 8.0g, join in the three-necked bottle, then add anhydrous methanol 80ml and anhydrous triethylamine 5.0ml in the three-necked bottle , after fully stirring to make it dissolve, place the three-necked flask in an ice bath, and when the temperature drops to 15°C, slowly drop 5ml of methanol solution of sodium methoxide (concentration is 0.1mol / L) with a dropper to adjust The pH value is 10, the dropwise addition time is 60 minutes, and the methanol solution of sodium methoxide is added dropwise and reacted for 30 minutes under stirring. Then add the prepared above-mentioned reaction solution into a rotary evaporator, the temperature of the water-soluble pot is 60° C., and the pressure is 0.01 MPa. After the rotary evaporator drains the solvent, amoxicillin sodium crystallizes out, and the obtained wet amoxicillin The sodium is sent to a vacuum drying oven at 45° C. under a pre...

Embodiment 3

[0064] A kind of synthetic method of penicillin potassium salt, is to get the dried amoxicillin trihydrate 5.0g, join in the three-necked bottle, then add anhydrous methanol 60ml and anhydrous triethylamine 2.5ml in the three-necked bottle , after fully stirring to make it dissolve, place the three-necked flask in an ice bath, and when the temperature drops to 10°C, slowly drop 4ml of methanol solution of potassium methylate (concentration is 0.1mol / L) with a dropper to adjust The pH value is 9, the dropwise addition time is 28 minutes, and the methanol solution of potassium methoxide is added dropwise and reacted for 25 minutes under stirring. Then add the prepared above-mentioned reaction solution into a rotary evaporator, the temperature of the water-soluble pot is 50° C., and the pressure is 0.1 MPa. After the rotary evaporator drains the solvent, amoxicillin sodium crystallizes out, and the obtained wet amoxicillin The sodium is sent to a vacuum drying oven at 43°C under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com