Highland barley undertint beer and preparation method thereof

A light-colored, beer technology, applied in the field of beer, can solve the problems of rough taste of beer, complex preparation method, low nutritional content, etc., and achieve the effects of preventing cardiovascular diseases, low cost, and reducing cholesterol content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

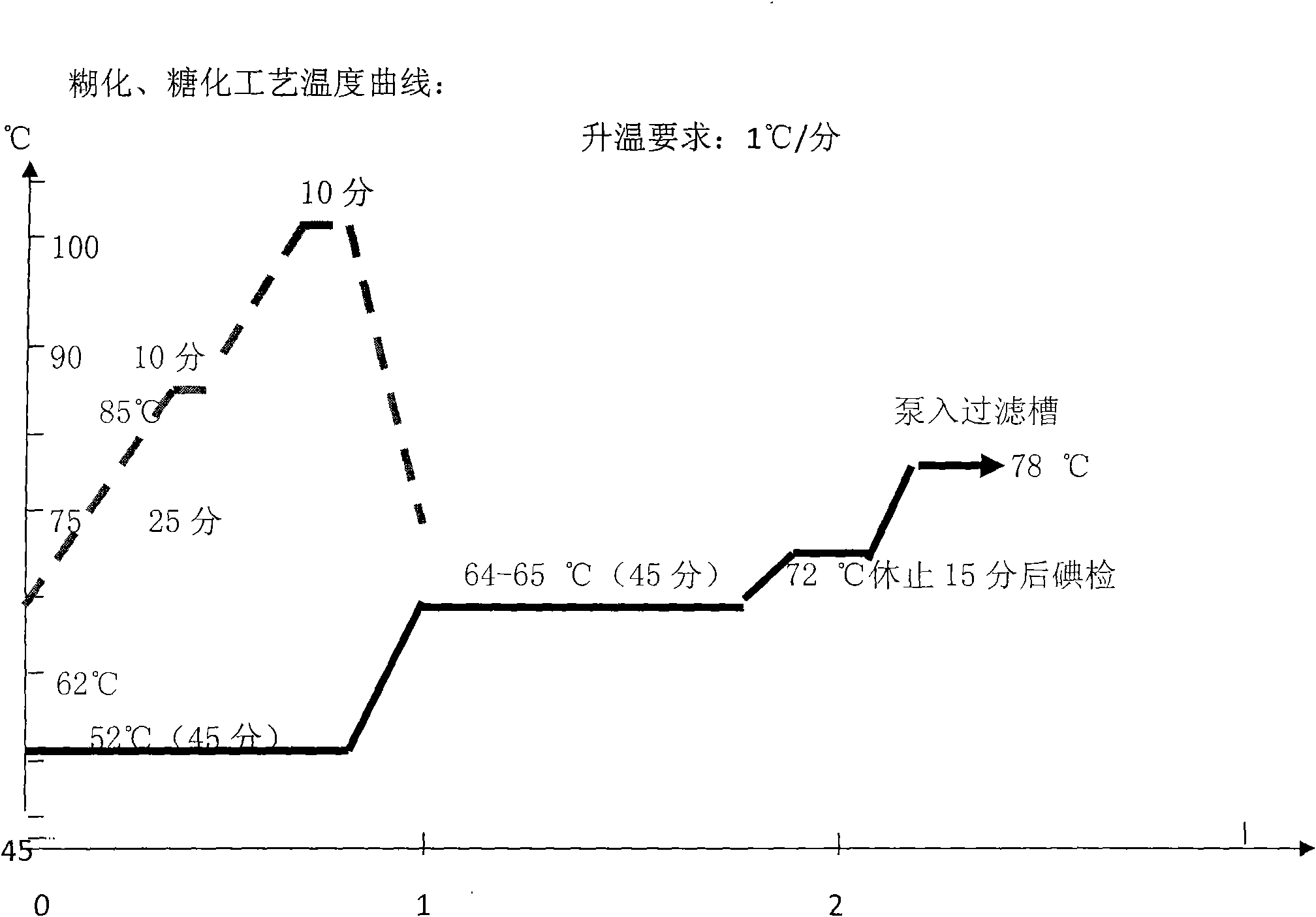

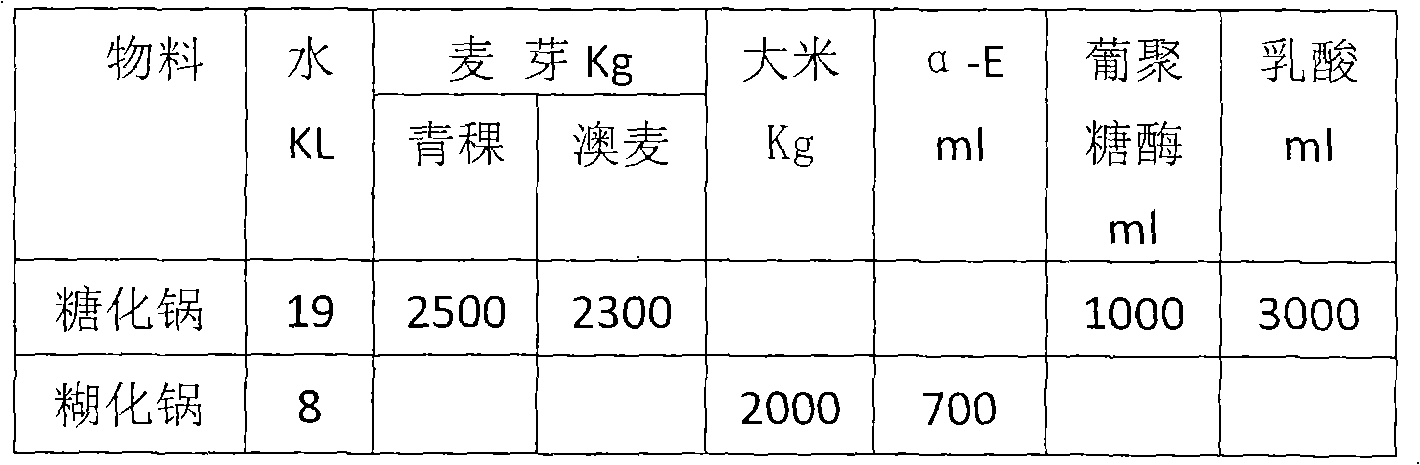

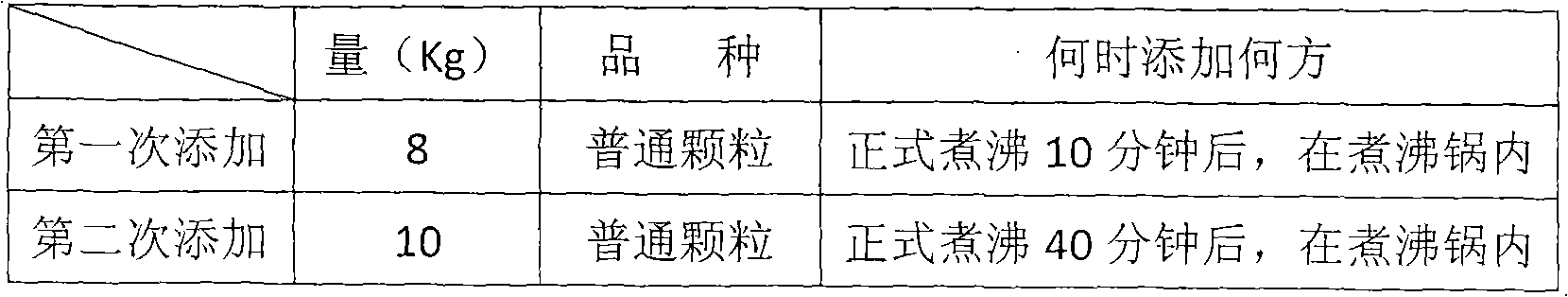

Method used

Image

Examples

Embodiment 1

[0026] A kind of highland barley light-colored beer, described highland barley light-colored beer is prepared from the following raw materials by weight percentage: In the total feeding, highland barley light-colored malt accounts for 60%, light-colored barley malt accounts for 30%, and rice accounts for 5%, according to 20ppm The α-acid content is added granular hops, with 0.45% brewer's yeast (mud), amylase 20ppm, dextranase 15ppm, lactic acid 60ppm, carrageenan 35ppm, protease 12ppm, total material water ratio 1: 3.8. Among them, the highland barley malt is highland barley light-colored malt made from Tibetan Green 320#, the light-colored barley malt is selected from high-grade Australian malt, the rice is selected from high-quality rice, and the granular hops are 90-type granules. The high-quality strains of the first generation of beer yeast, water The pollution-free groundwater in Tibet is used, the total hardness is controlled at 3°dh, and the pH is 6.6.

Embodiment 2

[0028] A kind of highland barley light-colored beer, described highland barley light-colored beer is prepared from the following raw materials by weight percentage: In the total feeding, highland barley light-colored malt accounts for 35%, light-colored barley malt accounts for 40%, and rice accounts for 10%, according to 30ppm The α-acid content of adding granular hops, with 0.9% brewer's yeast (mud), amylase 10ppm, dextranase 5ppm, lactic acid 30ppm, carrageenan 20ppm, protease 5ppm, total material water ratio 1: 4.6. The highland barley malt used is highland barley light-colored malt made from Tibetan Green 148#. The light-colored barley malt is made of high-grade Australian malt, the rice is high-quality rice, the hops are fragrant granules, the first generation of beer yeast is a high-quality strain, and the water is made of The pollution-free groundwater in Tibet has a total hardness of 8°dh and a pH of 8.0.

Embodiment 3

[0030] A kind of highland barley light-colored beer, described highland barley light-colored beer is prepared from the following raw materials by weight percentage: In the total feeding, highland barley light-colored malt accounts for 40%, light-colored barley malt accounts for 35%, and rice accounts for 5%, according to 25ppm The α-acid content of granule hops is added, with 0.7% brewer's yeast (mud), amylase 10ppm, dextranase 10ppm, lactic acid 30ppm, carrageenan 30ppm, protease 8ppm, total material water ratio 1: 4.2. The highland barley malt used is highland barley light-colored malt made from Tibetan Green 320#, the light-colored barley malt is selected from high-grade Australian malt, the rice is selected from high-quality rice, and the granulated hops are 90-type granules. The high-quality strains of the second generation of brewer's yeast , the water adopts west

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com