Method for preventing and controlling nitrogen blockage of argon preparation system of space division device

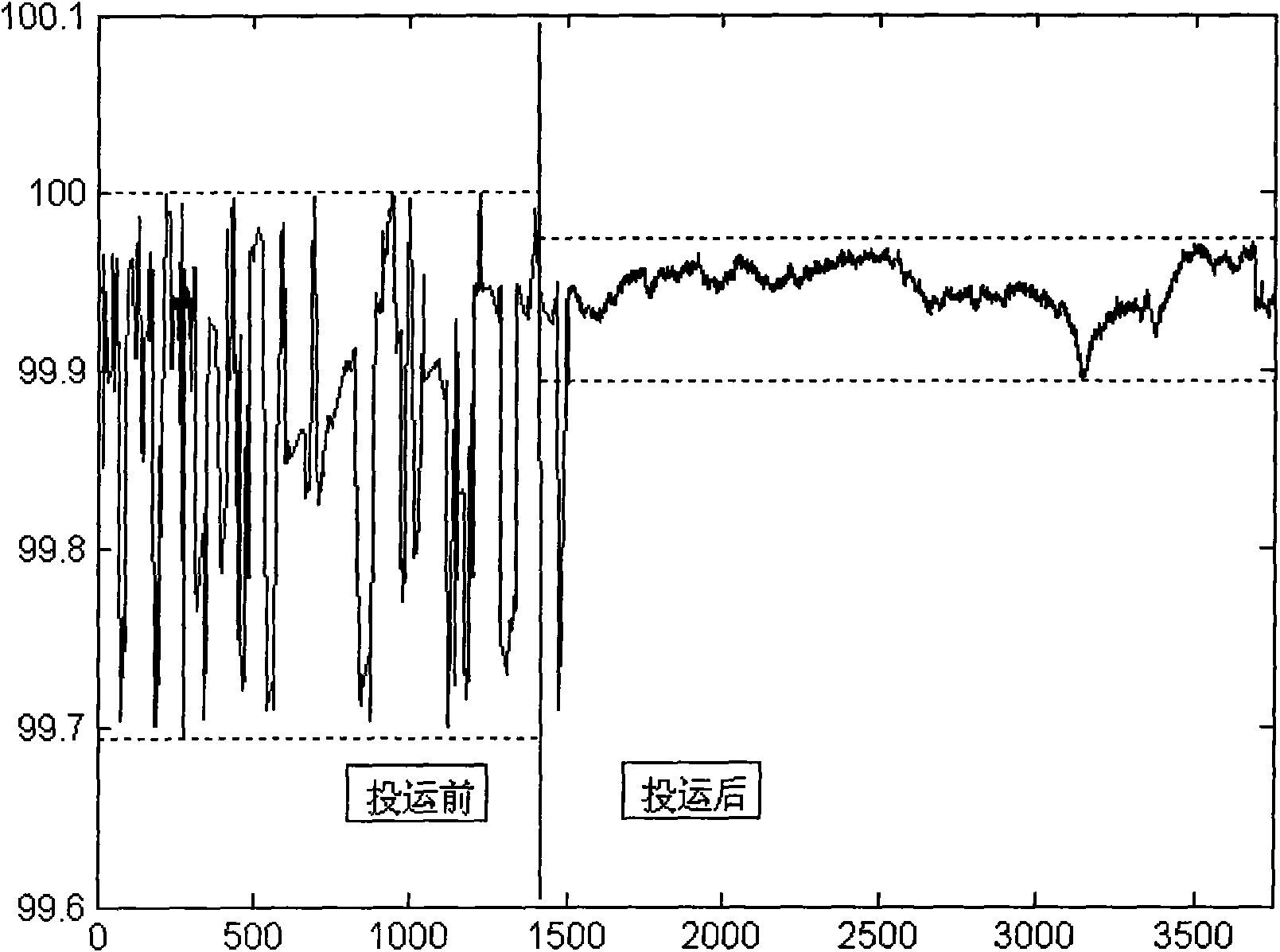

An air separation device, prevention and control technology, applied in the sequence/logic controller program control, cold treatment separation, refrigeration and liquefaction, etc., can solve the problems of lack of automatic prevention and control of nitrogen plug control methods, etc., to achieve convenient online calculation, Effect of overcoming influence, satisfactory control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and by embodiment the present invention will be further described:

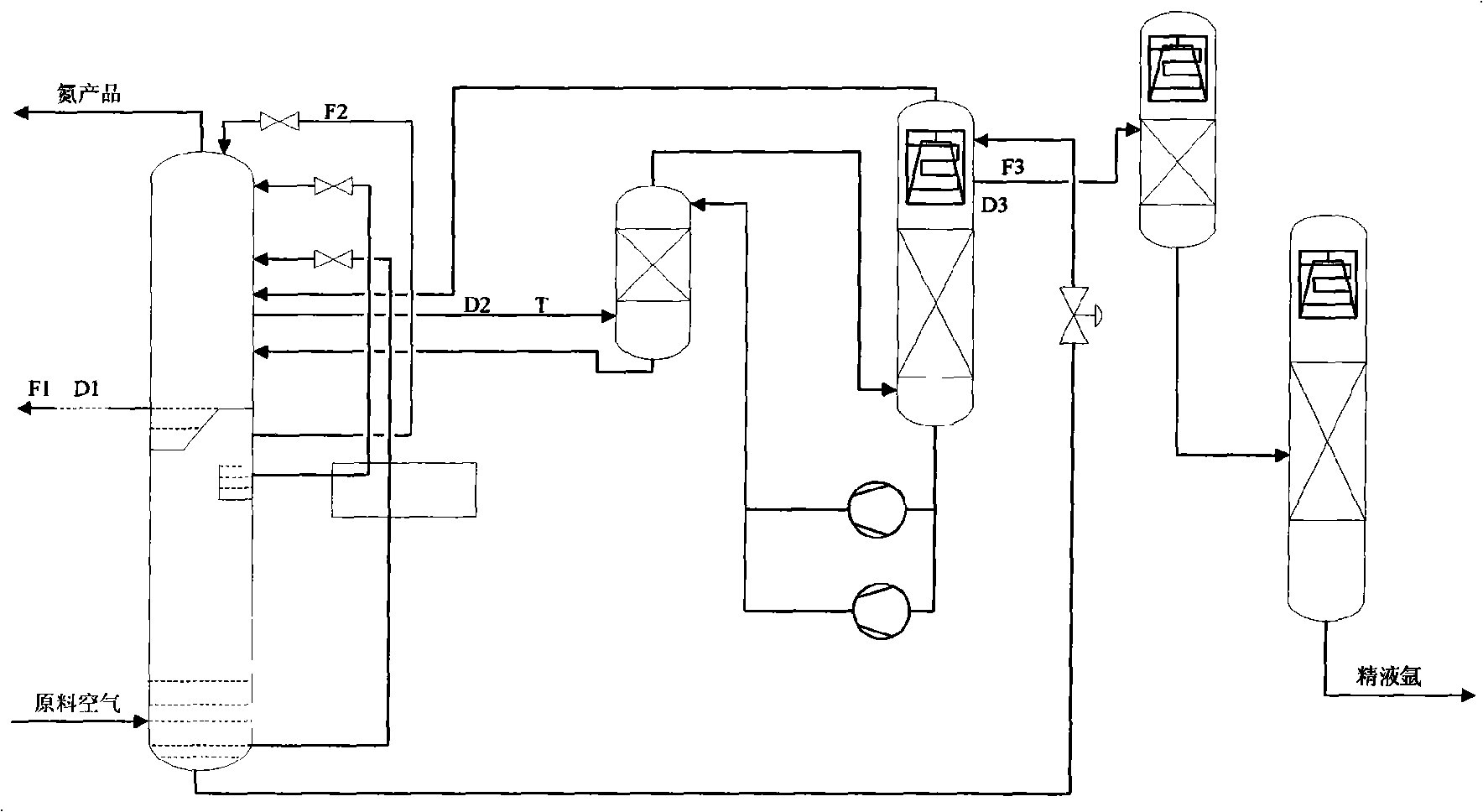

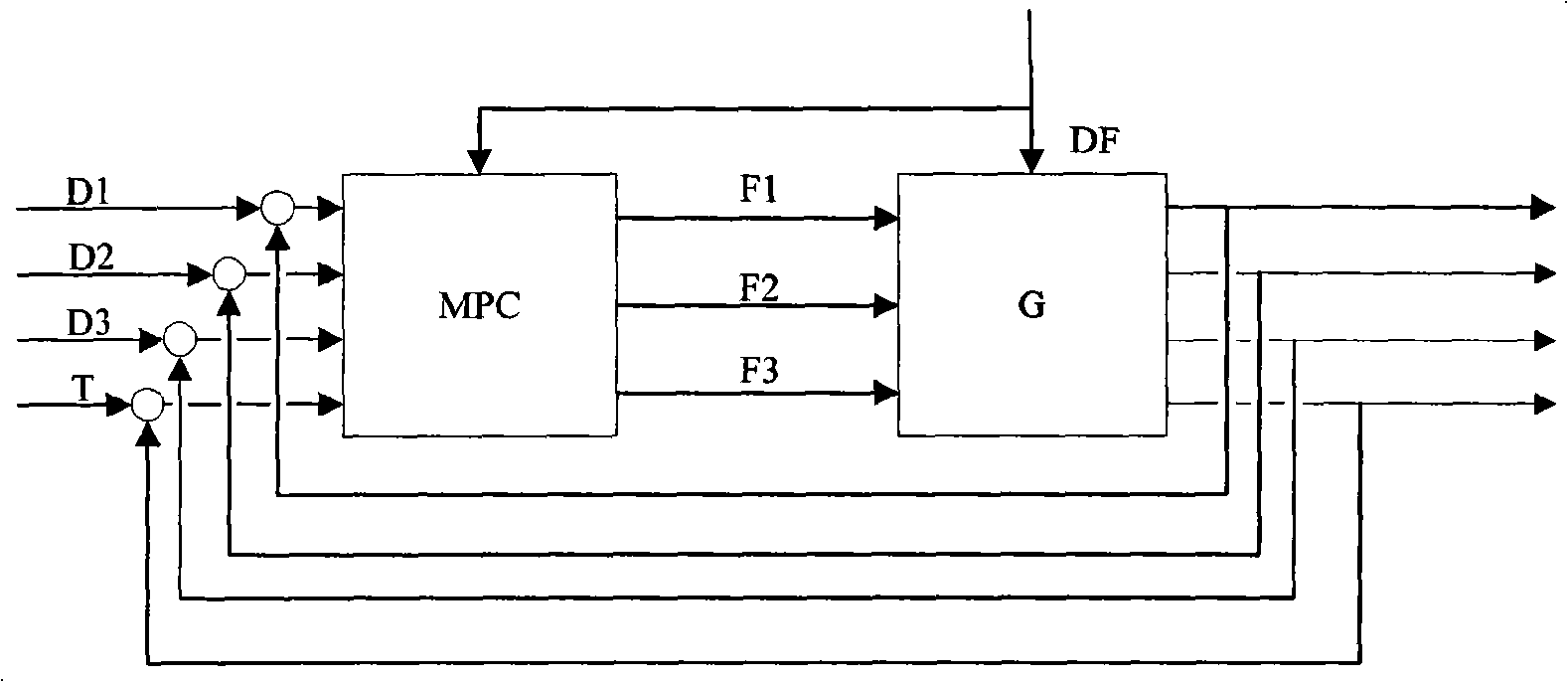

[0035] The structure diagram of the control principle of the nitrogen plug in the argon system of the air separation unit of the present invention is as follows figure 2 As shown, it is by selecting the measured values of the argon content of the argon fraction, the argon fraction temperature, the argon content at the top of the crude argon tower II and the product oxygen purity as controlled variables (CVs), wherein the argon content of the argon fraction, The temperature of the argon distillate is used as the first line of defense to monitor whether nitrogen plugging occurs in the argon production system, and the argon content at the top of the crude argon tower II is used as the second line of defense. The stability of the working conditions is the most fundamental means to prevent nitrogen plugging in the argon system; the amount of oxygen taken out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com