Trichoderma reesei alpha-amylase is a maltogenic enzyme

A technology of Trichoderma reesei and amylase, applied in the directions of enzymes, biochemical equipment and methods, enzymes, etc., can solve the problems such as the difficulty in achieving glucose concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0164] 4.1. Preparation of starch substrate

[0165] Those of ordinary skill in the art will be well aware of available methods that can be used to prepare starch substrates for use in the methods disclosed herein. For example, useful starch substrates may be obtained from tubers, roots, stems, legumes, cereals or whole grains. More specifically, granular starch may be obtained from corn, ear of corn, wheat, barley, rye, millet, sago, cassava, tapioca, sorghum, rice, pea, bean, banana or potato . Corn contains about 60-68% starch; barley contains about 55-65% starch; millet contains about 75-80% starch; wheat contains about 60-65% starch; and polished rice contains 70-72% starch. Particularly contemplated starch substrates are corn starch and wheat starch. Starch from the grain may be ground or whole, and includes corn solids such as kernels, bran, and / or ears of corn. The starch may be highly refined raw starch or raw material from a starch refining process. A variety of...

Embodiment 1

[0225] 1.1 Cloning of TrAA gene

[0226] Using BIO101 Fast System, according to the method described by the supplier (Qbiogene, Inc., Irvine, CA), from potato dextrose broth (Difco TM Chromosomal DNA of Trichoderma reesei QM6a was isolated from mycelial pellets of liquid cultures in Cat. No. 254920). The DNA was purified using Quick spin columns (Qiagen, Inc., Valencia, CA; cat. no. 28106). Using primers with TrAA-specific sequences designed according to the predicted nucleotide sequence in the Trichoderma reesei genome database of the U.S. Department of Energy Joint Genome Research Institute, forward primer NSP331 (SEQ ID NO: 6: ATGAAGCTCCGGTACGCTCTCC) and reverse primer NSP332 (SEQ ID NO: 7: TCACGAAGACAGCAAGACAATGGGC) Isolated TrAA gene. The primers are flanked at the 5' end by attB sequence (Invitrogen Corp., Carlsbad, CA). Trichoderma reesei QM6a chromosomal DNA was used as template.

[0227] PCR mix contains the following components: 4 μL forward primer (10 μM); 4...

Embodiment 2

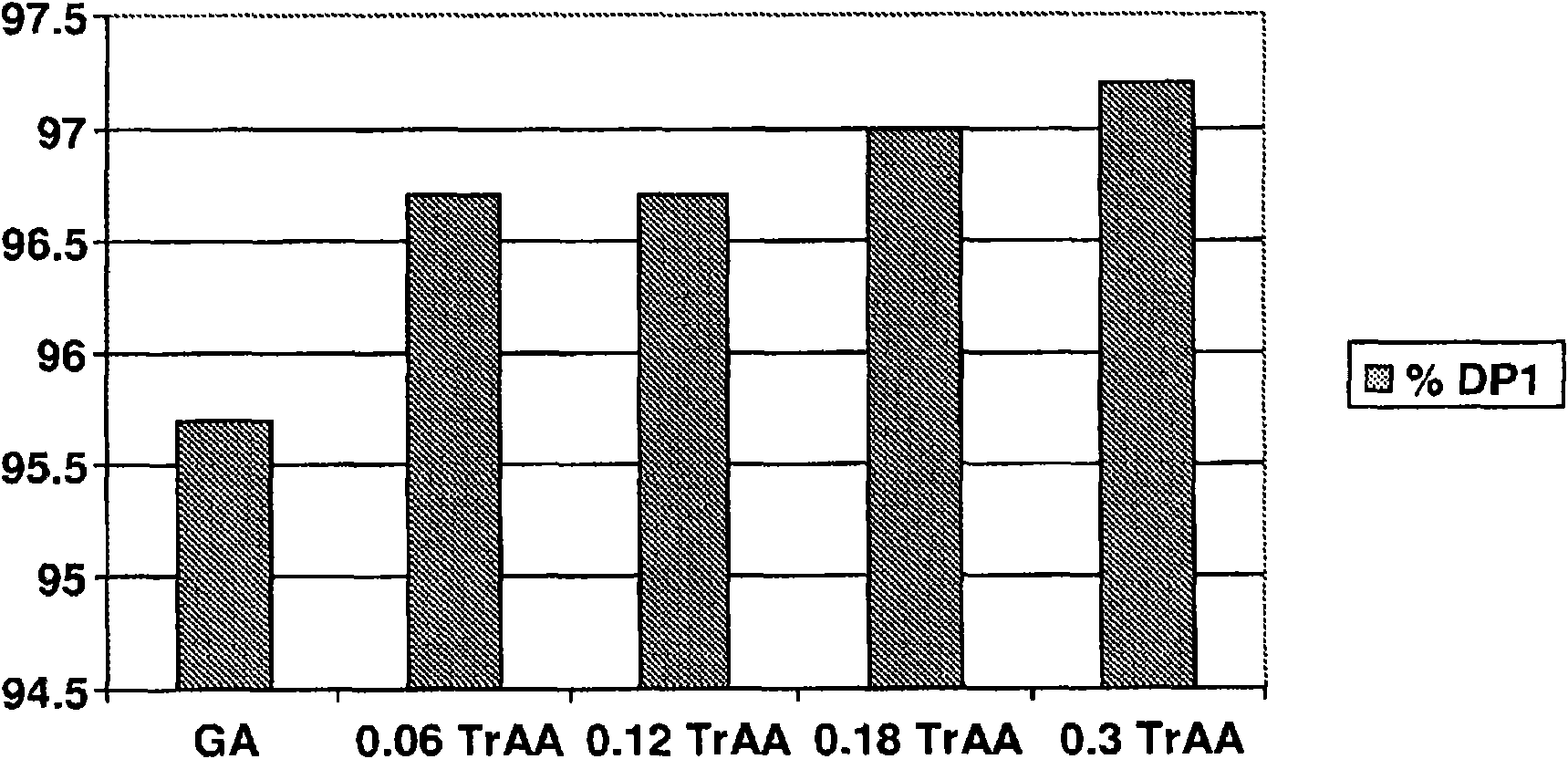

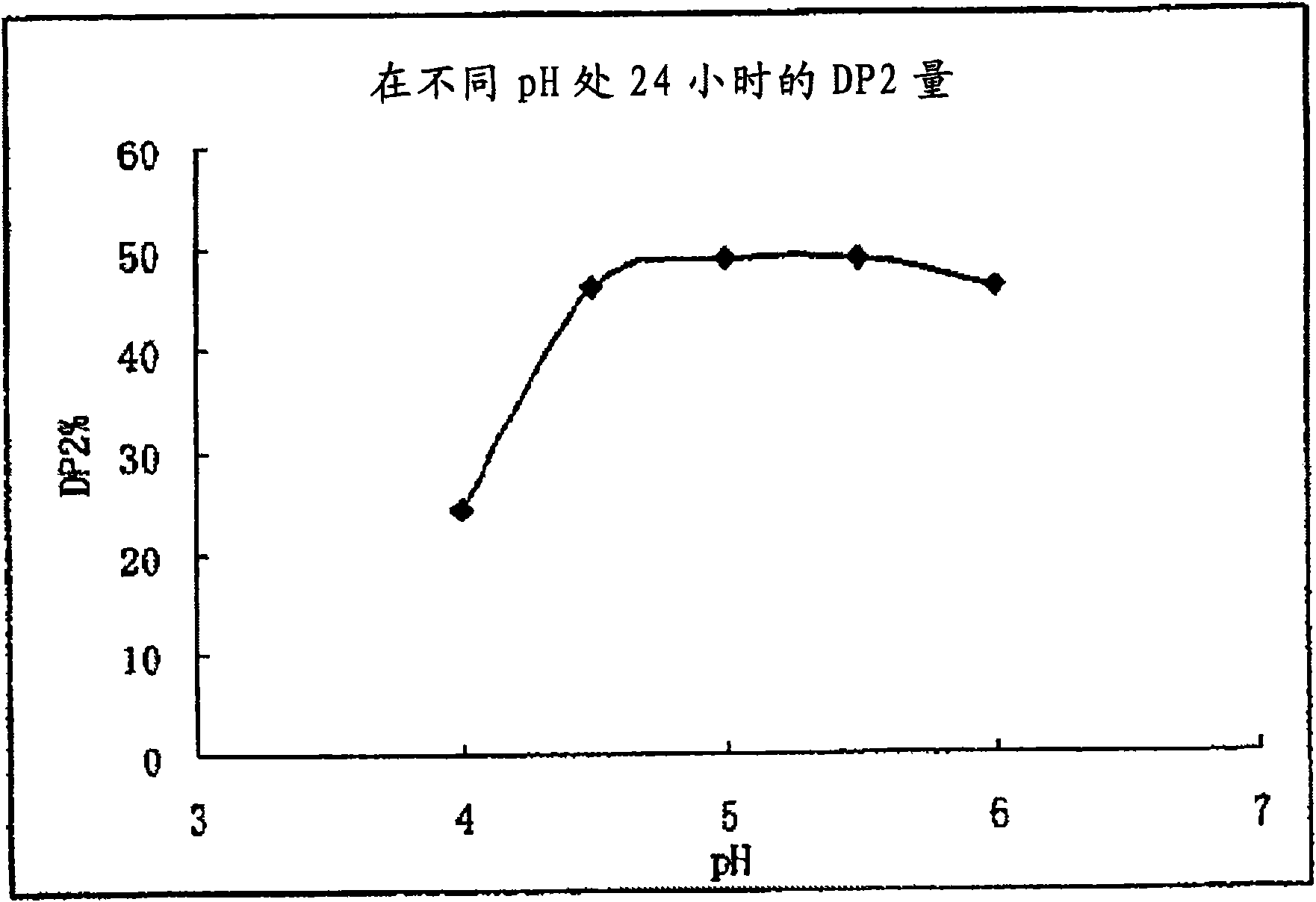

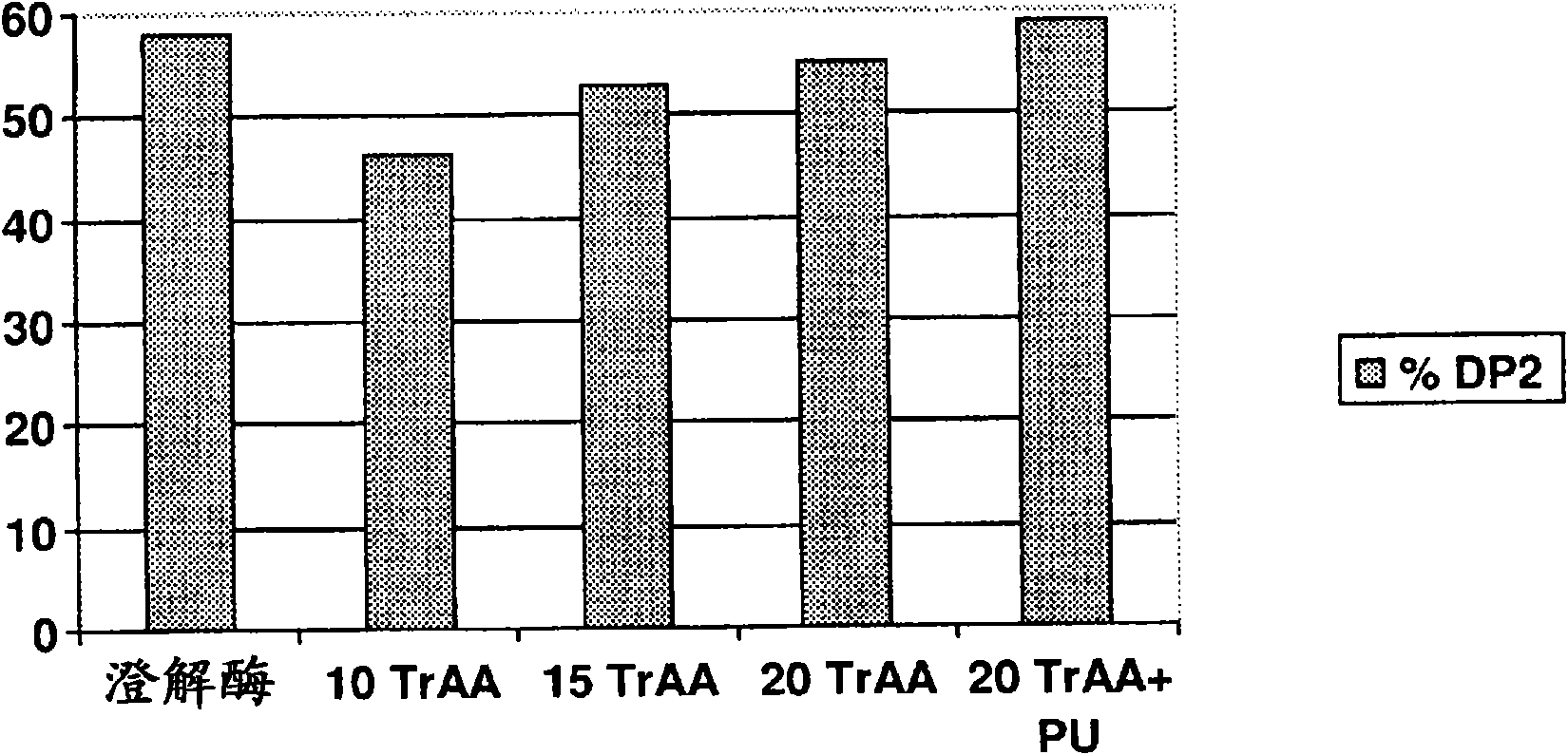

[0241] TrAA is used to increase the yield of glucose in saccharification reactions catalyzed by glucoamylases at low pH. TrAA (Lot No. GCI2004017 / 018-UF) was purified as described in Example 1, Section 1.3. Glucoamylase was from GA-L, Lot No. 901-04290-001 (Genencor International, Inc.), with an activity of 385 GAU / g. The substrate consisted of a liquefied starch substrate prepared as follows: 745 g of raw cornstarch was diluted with water to give a slurry of 32% w / w ds. Addition of thermostable bacterial alpha-amylase Ethyl (Genencor International, Inc.) Lot No. 107-04107-001 to a concentration of 0.3 kg / mt ds, and the solution was liquefied at 92°C for 25 minutes. Using methods well known in the art, an iodine test was performed to measure residual starch concentration.

[0242] The liquefied starch was cooled to 60°C and the pH was adjusted to 4.2 with 20% v / v sulfuric acid. Add TrAA and 4060, and the reaction was carried out at 60°C for 30 hours. At the conclusion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com