Method for separating superfine powder

A technology of ultra-fine powder and powder, which is applied in the direction of solid separation, wet separation, chemical instruments and methods, etc. It can solve the problems of inability to classify, poor classification accuracy, and high water consumption, and achieve wide application range and high classification speed. Fast and high separation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

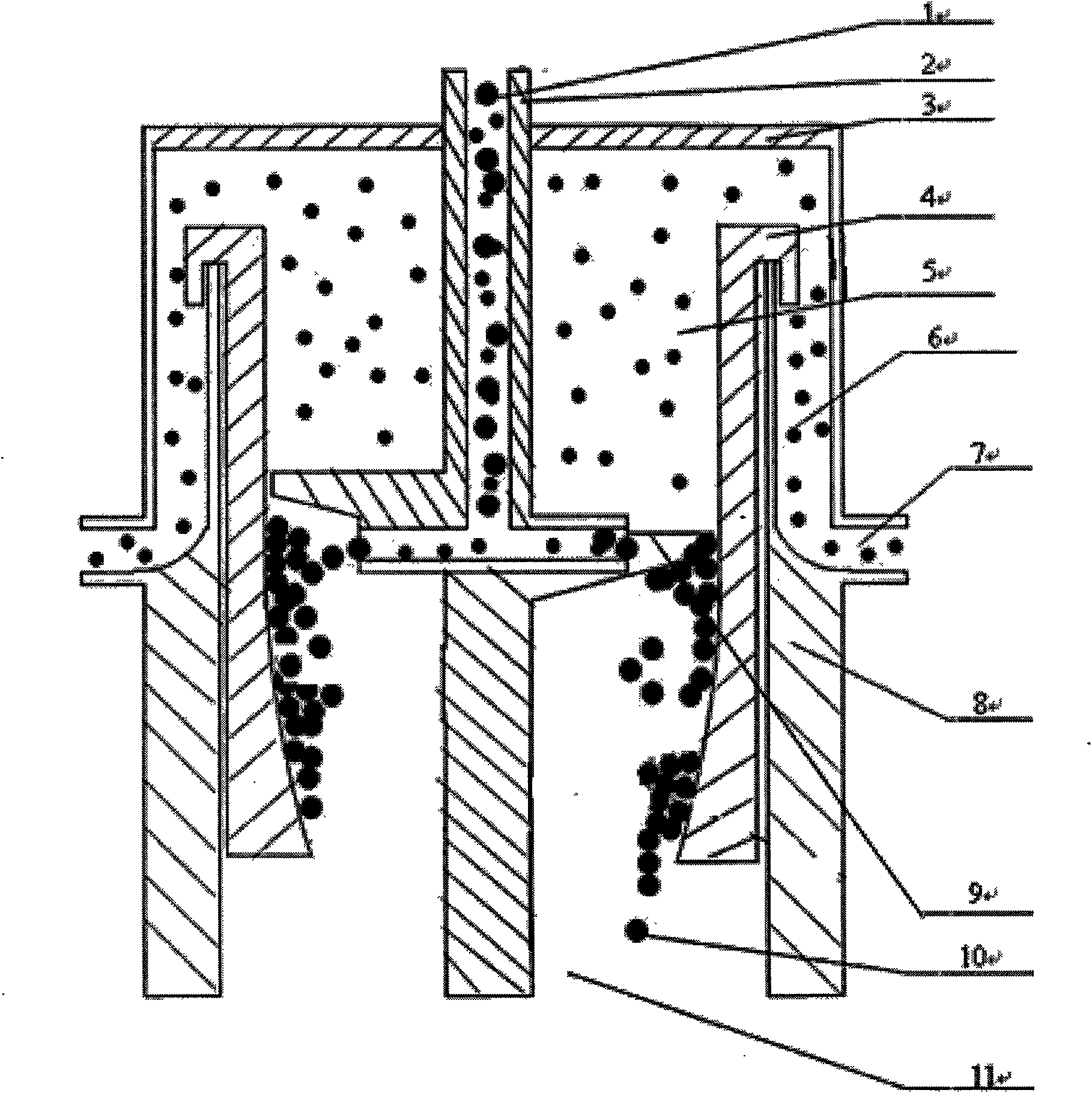

[0019] The specific implementation of this solution will be described in detail below in conjunction with the technical solution and accompanying drawings.

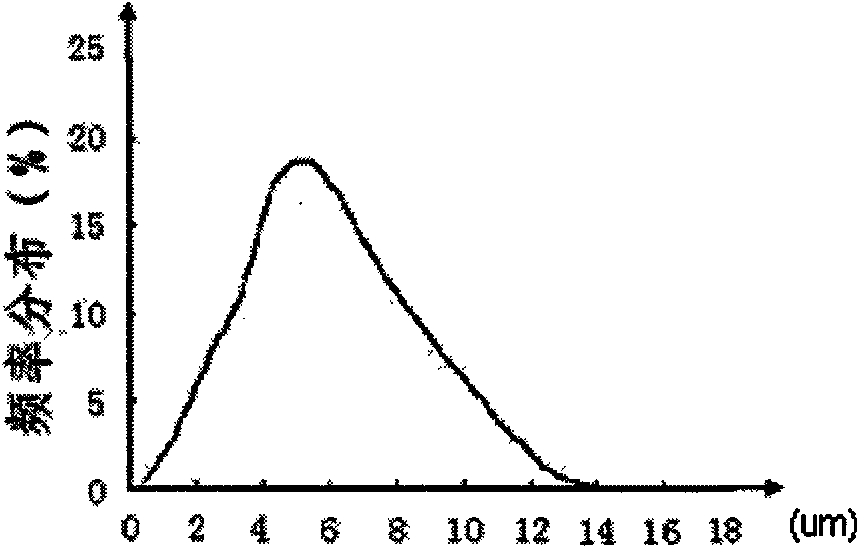

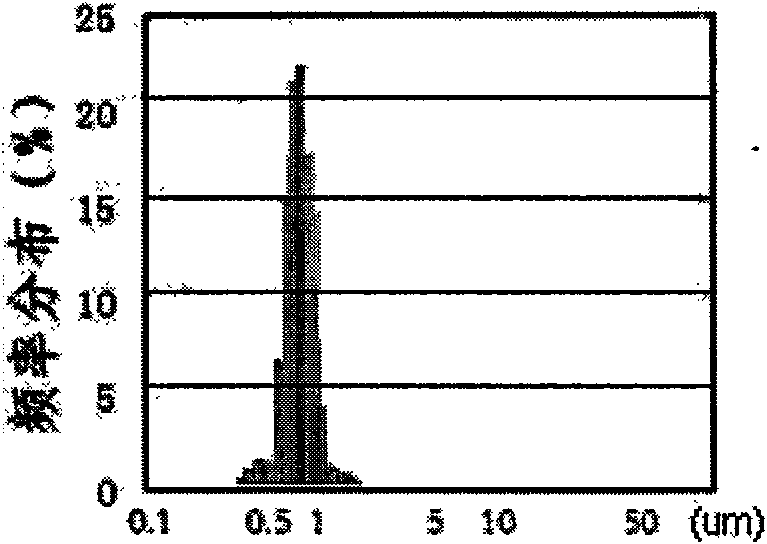

[0020] This method applies the principle of centrifugation. Under the action of centrifugal force, the particles with a density higher than water will be thrown onto the rotating outer cylinder 4. Since the rotating outer cylinder 4 and the rotating inner cylinder 2 have a rotation speed difference of 0.1-10 revolutions, the While the inner and outer cylinders are running at high speed, the rotating inner cylinder 2 moves relative to the rotating outer cylinder 4 . Because the blade 9 is installed on the rotating inner cylinder 2, the particles thrown onto the rotating outer cylinder 4 can be hung down by the tip of the blade 9 and discharged from the coarse powder outlet 11. The fine powder will be discharged from the fine powder discharge port 7 together with water to achieve the effect of separation. This method can e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com