Method for optimizing operation of desalting system of ion exchanger

An ion exchanger and system optimization technology, applied in the field of optimal operation of ion exchanger desalination systems, can solve the problems of difficult production activities, high operating costs, unreasonable control of regenerant consumption, etc., and achieve the effect of ensuring qualified water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

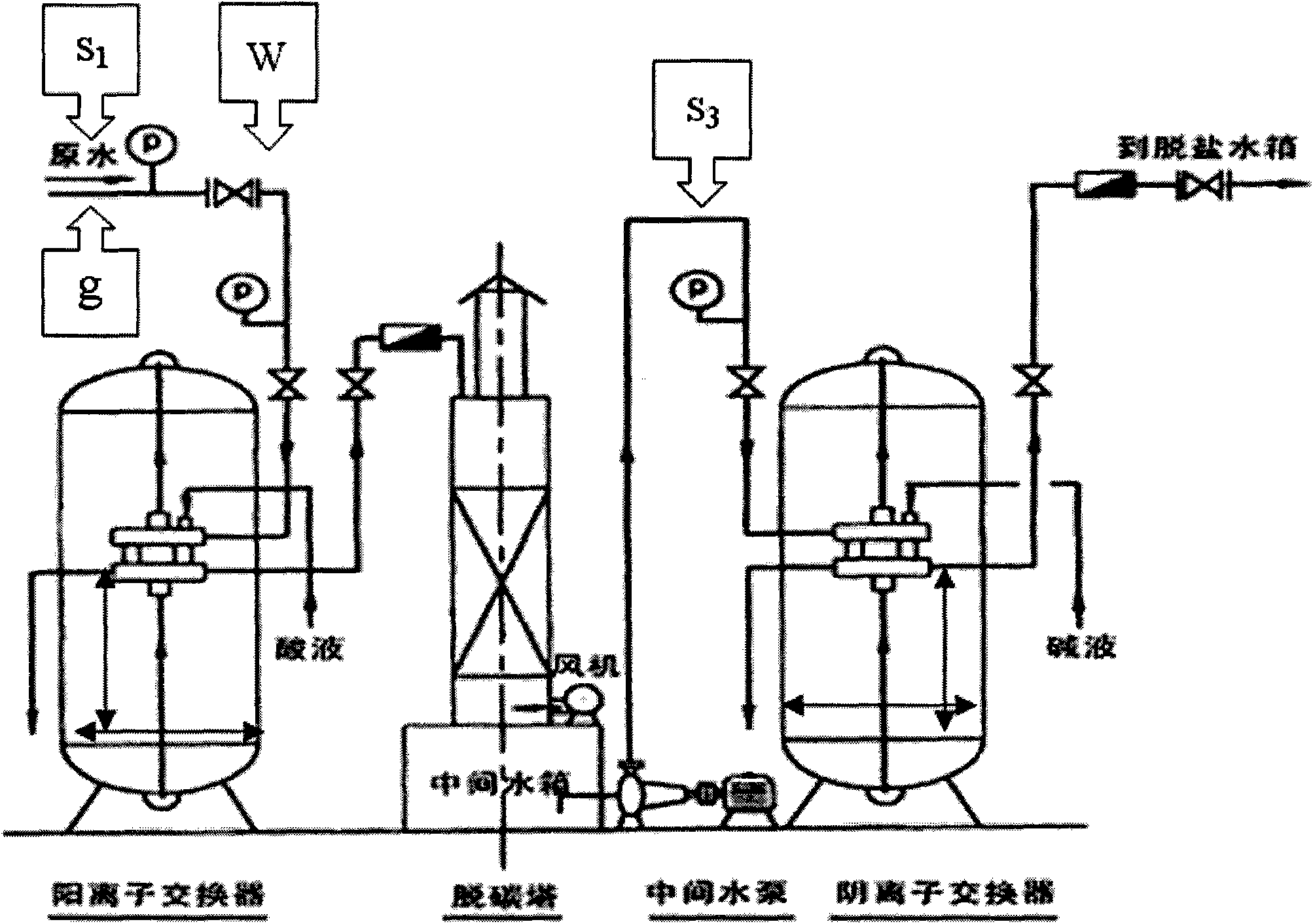

[0047] Such as figure 1 As shown, in the ion exchanger desalination system provided by the present invention, the raw water enters the cation exchanger to replace the cations in the water and replace them with hydrogen ions. Replace the anions in the water with hydroxide ions, and finally enter the desalted water tank to obtain qualified water.

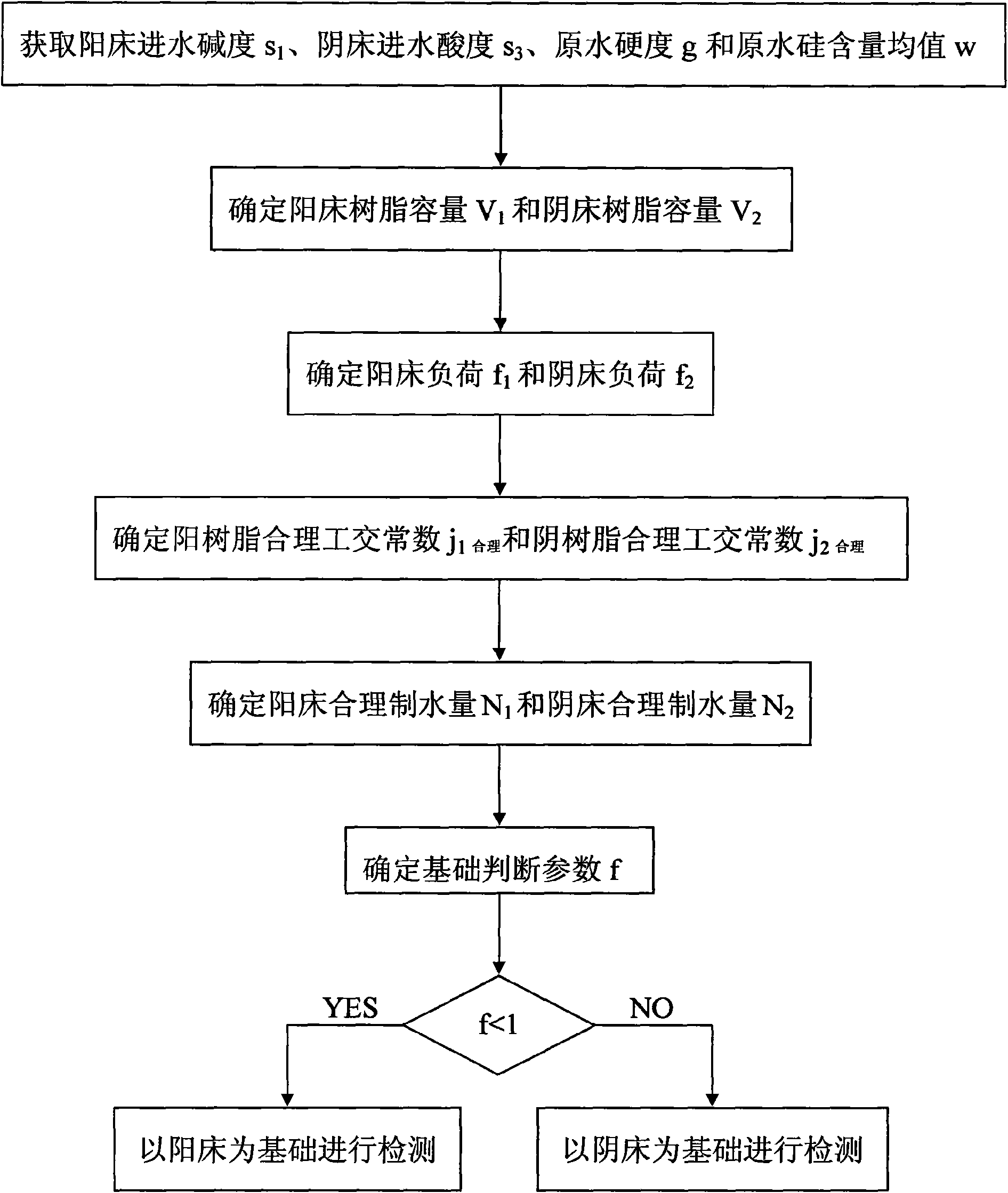

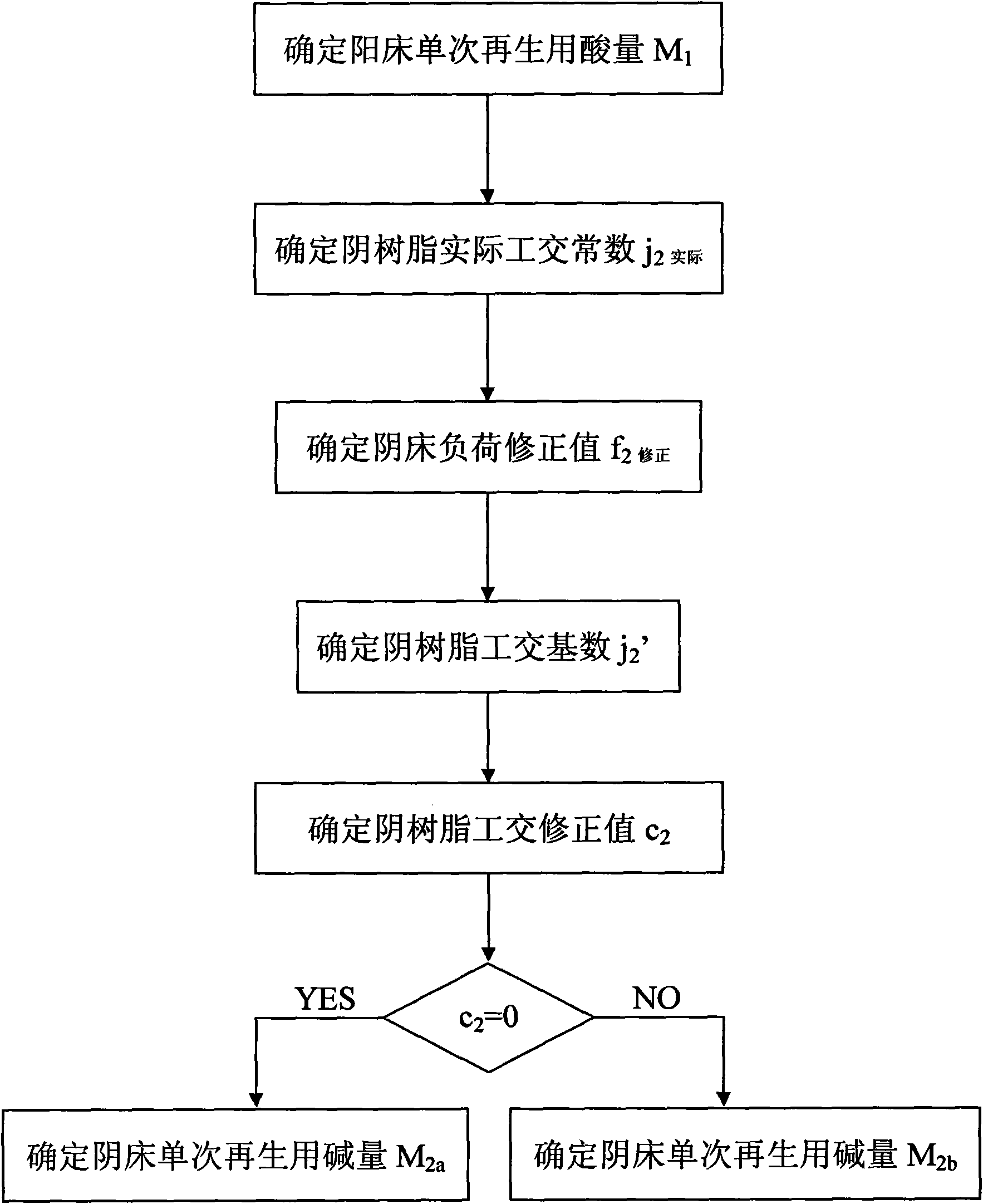

[0048] Install a silicon meter at the inlet pipe of the cation exchanger or use a portable silicate analyzer to measure the average active silicon content w of the raw water, install a hardness analyzer or use a chemical titration method to measure the raw water hardness g, install an alkalinity detector or use a chemical titration method Measure the alkalinity s of the influent water of the positive bed 1 ; Install an acidity detector on the inlet pipeline of the anion exchanger or use a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com