Bacterial leaching copper method of complex chalcopyrite flotation tailings

A technology for flotation tailings and chalcopyrite type, which is applied to the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of many copper-containing minerals, which have not been effectively developed and utilized, and achieve environmentally friendly operation , Alleviate the shortage of copper resources, the effect of good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

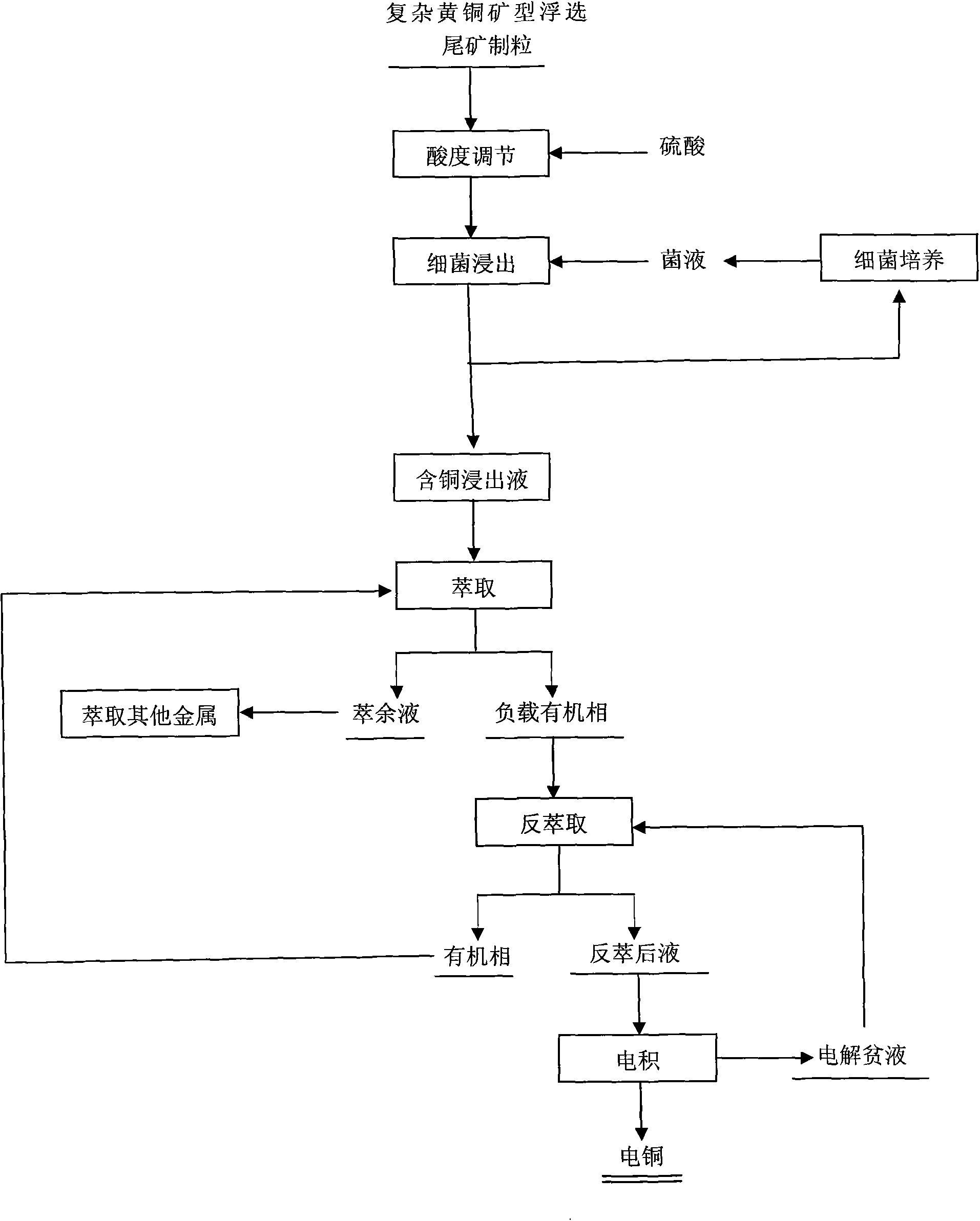

Method used

Image

Examples

Embodiment 1

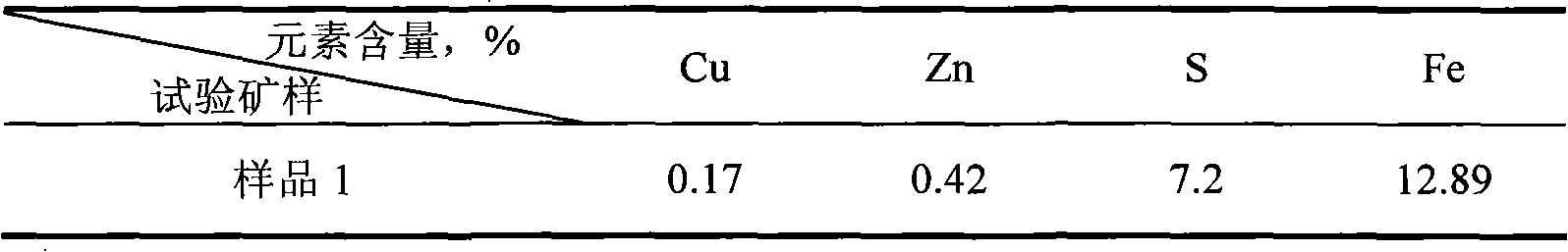

[0022] The chemical analysis of flotation tailings sample 1 is shown in Table 2.

[0023] Table 2 Chemical composition analysis of tailing sample 1

[0024]

[0025] step:

[0026] (1) Granulation: Mix the flotation tailings, cement of model 32.5 and water in a volume ratio of 6:1:2 to make granules of 10mm-20mm, and air dry them naturally.

[0027] (2) Bacterial culture: inoculate the mixed bacterial liquid containing Thiobacillus ferrooxidans and Microspirillum ferrooxidans in a 20L organic glass bacterial oxidation tank with a stirring device, inoculate it into 9K medium, and carry out expanded culture. The volume ratio of the inoculum is: strain: medium = 1:10, the culture temperature is 25°C, the pH of the culture solution is 1.0-2.0, and the culture time is 48 hours.

[0028] (3) Flotation tailings acidity adjustment: The prepared flotation tailings particles are packed in a φ90×900mm plexiglass column, and the MP-20RZ magnetic drive circulating pump is used to spray the concen...

Embodiment 2

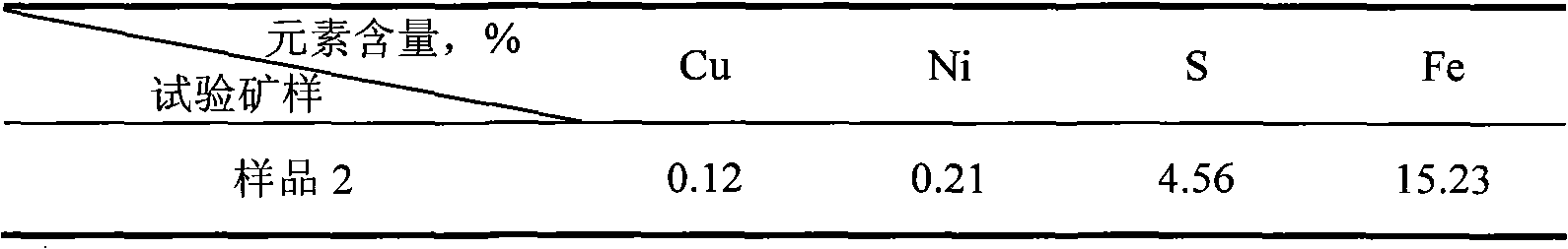

[0034] The chemical analysis of flotation tailings sample 2 is shown in Table 3.

[0035] Table 3 Tailings sample 2 Chemical composition analysis

[0036]

[0037] step:

[0038] (1) Granulation: Mix the tailings, cement of model 32.5 and water at a volume ratio of 5:1:2 to make granules of 10mm-20mm, and air dry them naturally.

[0039] (2) Bacterial culture: inoculate the mixed bacterial liquid containing Thiobacillus ferrooxidans and Microspirillum ferrooxidans in a 20L organic glass bacterial oxidation tank with a stirring device, inoculate it into 9K medium, and carry out expanded culture. The volume ratio of the inoculum is: strain: medium = 1:15, the culture temperature is 47°C, the pH value of the culture solution is 1.0-2.0, and the culture time is 24 hours.

[0040] (3) Flotation tailings acidity adjustment: the prepared flotation tailings particles are packed in a φ90×900mm plexiglass column, and the MP-20RZ magnetic drive is used to drive the circulating pump, and the con...

Embodiment 3

[0046] The chemical analysis of flotation tailings sample 3 is shown in Table 4.

[0047] Table 4 Tailings sample 3 chemical composition analysis

[0048]

[0049] step:

[0050] (1) Granulation: The flotation tailings, cement of model 42.5 and water are mixed in a volume ratio of 7:1:3 to form 10mm-20mm particles, and they are air-dried naturally.

[0051] (2) Bacterial culture: inoculate the mixed bacterial liquid containing Thiobacillus ferrooxidans and Microspirillum ferrooxidans in a 20L organic glass bacterial oxidation tank with a stirring device, inoculate it into 9K medium, and carry out expanded culture. The volume ratio of the inoculum is: strain: culture medium=1:20, the culture temperature is 60°C, the pH value of the culture solution is 1.0-2.0, and the culture time is 36 hours.

[0052] (3) Flotation tailings acidity adjustment: the prepared flotation tailings particles are packed in a φ90×900mm plexiglass column, and the MP-20RZ magnetic drive is used to drive the cir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com