Method and device for spraying silicic acid produced from oriented silicon steel having good bottom layer

A technology of oriented silicon steel and bottom layer, applied in the field of silicic acid spraying method and device, can solve the problems of reduced production efficiency, powder oxidation, affecting the formation of magnesium silicate bottom layer, etc., and achieves the effect of improving insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Produce grain-oriented silicon steel with the composition in the following table, and the composition is shown in Table 1:

[0075] Table 1

[0076]

[0077] A slab of the above composition was heated to 1180°C for 180 minutes. Then directly hot rolled to 2.3mm. The hot-rolled steel strip is annealed in two steps, first heated to 1130°C, and then lowered to 900°C in 200 seconds during the cooling process. The steel plate is subsequently quenched. After pickling, the steel strip is subjected to 5 passes of cold rolling, in which the 3rd and 4th passes are carried out at 220°C, and the thickness is reduced to 0.285mm. The cold-rolled steel strip is decarburized and annealed at 850°C for 200 seconds, and then nitriding is carried out at 700°C for 200 seconds. According to the following two processes for processing:

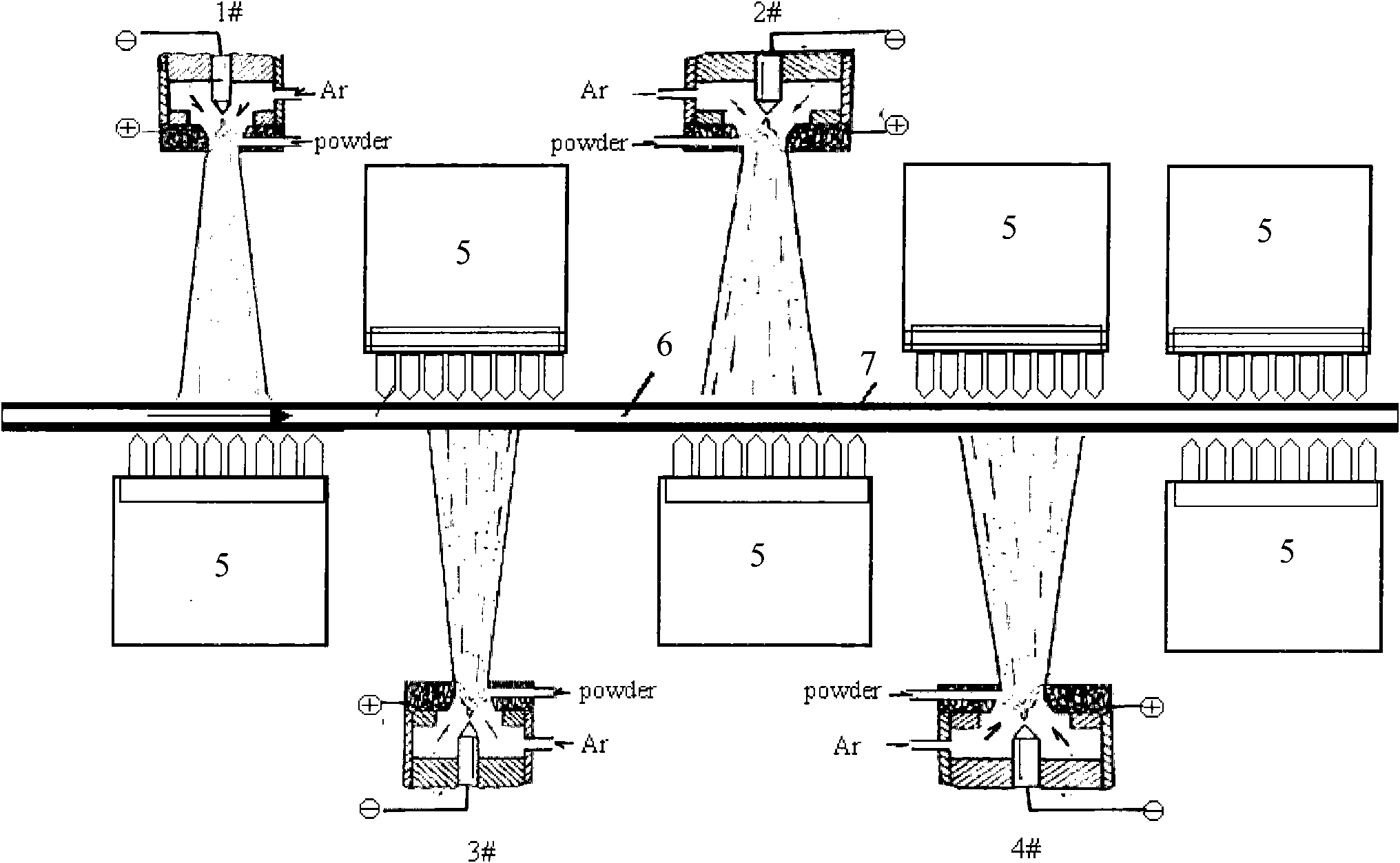

[0078] After decarburization annealing, plasma spray magnesium silicate on steel strip according to the following parameters: plasma gas flow r...

Embodiment 2

[0086] After the steel strip with the above composition is processed to decarburization by the process in Example 1, different plasma spraying magnesium silicate processes are adopted, wherein:

[0087] 1. The gas flow rate is 14L / min, the distance between 1# and 3# plasma sources is 100mm, the distance between 2# and 4# plasma sources is 100mm, and the spraying time is 200S;

[0088] 2. The gas flow rate is 16L / min, the distance between 1# and 3# is 100mm, the distance between 2# and 4# is 100mm, and the spraying time is 200S;

[0089] 3. The gas flow rate is 20L / min, the distance between 1# and 3# is 100mm, the distance between 2# and 4# is 100mm, and the spraying time is 200S;

[0090] 4. The gas flow rate is 20L / min, the distance between 1# and 3# is 150mm, the distance between 2# and 4# is 100mm, and the spraying time is 200S;

[0091] 5. The gas flow rate is 20L / min, the distance between 1# and 3# is 150mm, the distance between 2# and 4# is 100mm, and the spraying time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com