Direct heating type testing method of high temperature resistance of carbon/carbon heating elements

A heating element, heating technology, applied in the measurement of resistance/reactance/impedance, measurement of electrical variables, measurement devices, etc., can solve the problem of high test difficulty, and achieve the effect of solving the problem of high test difficulty, wide application range and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

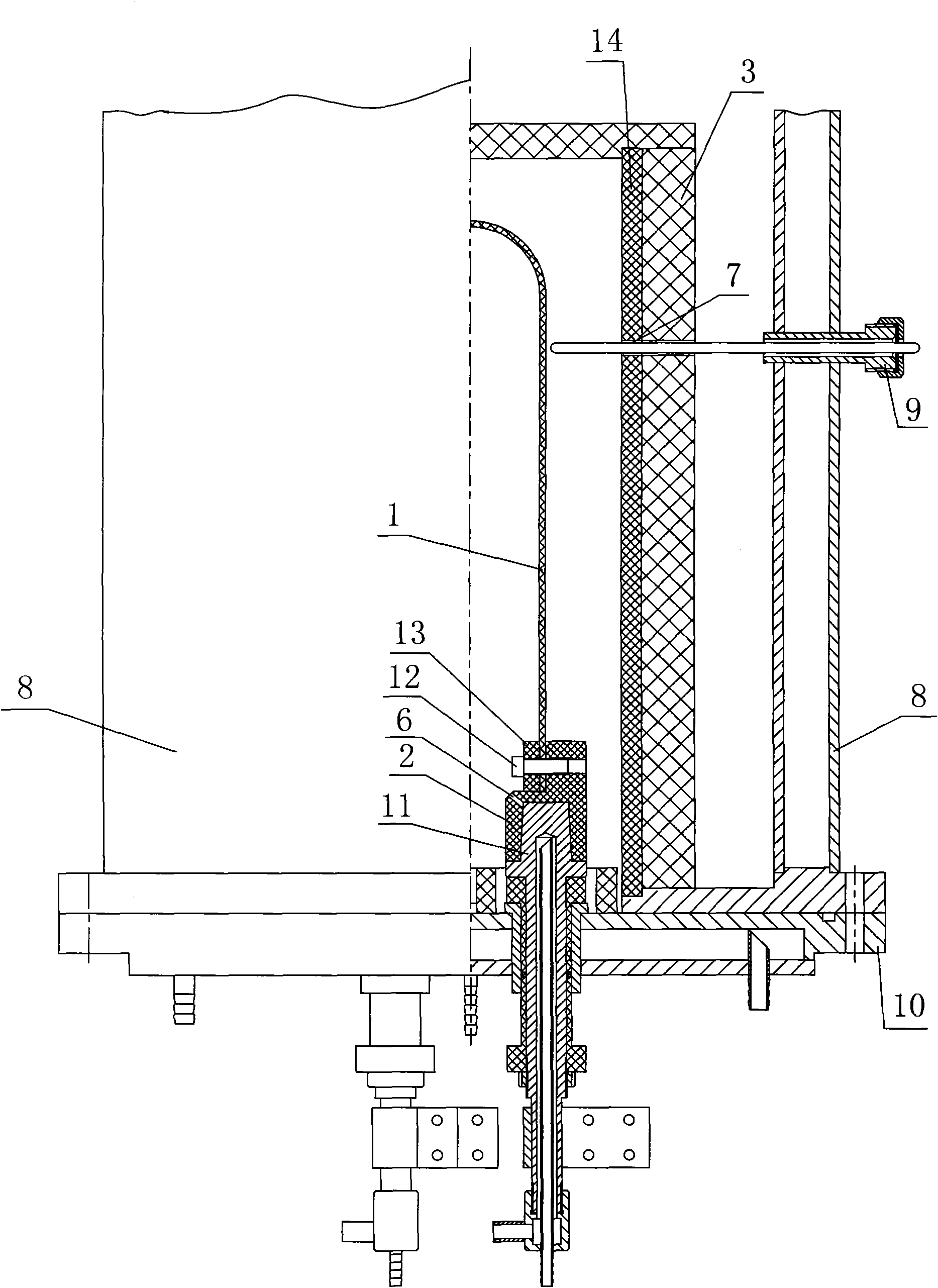

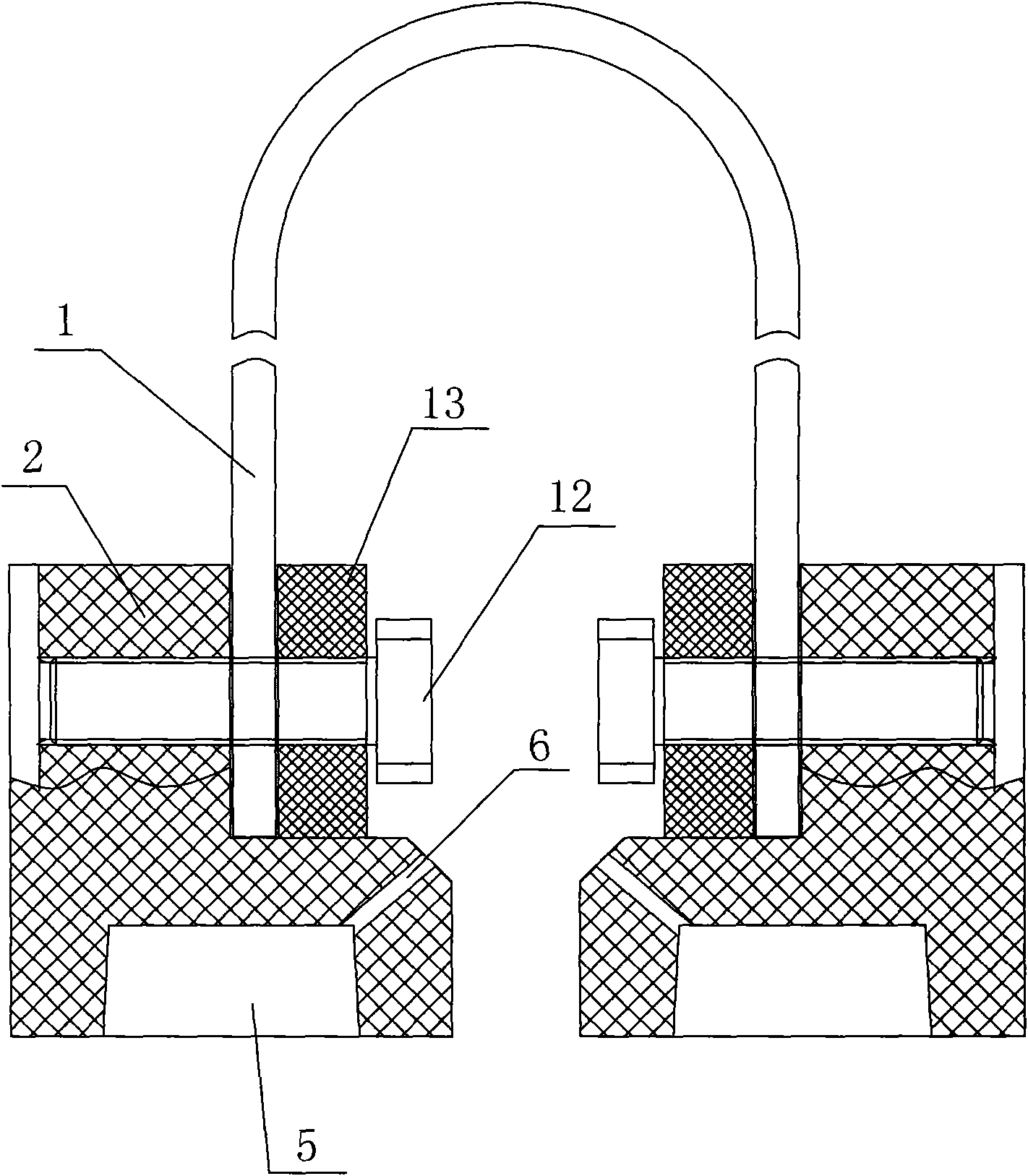

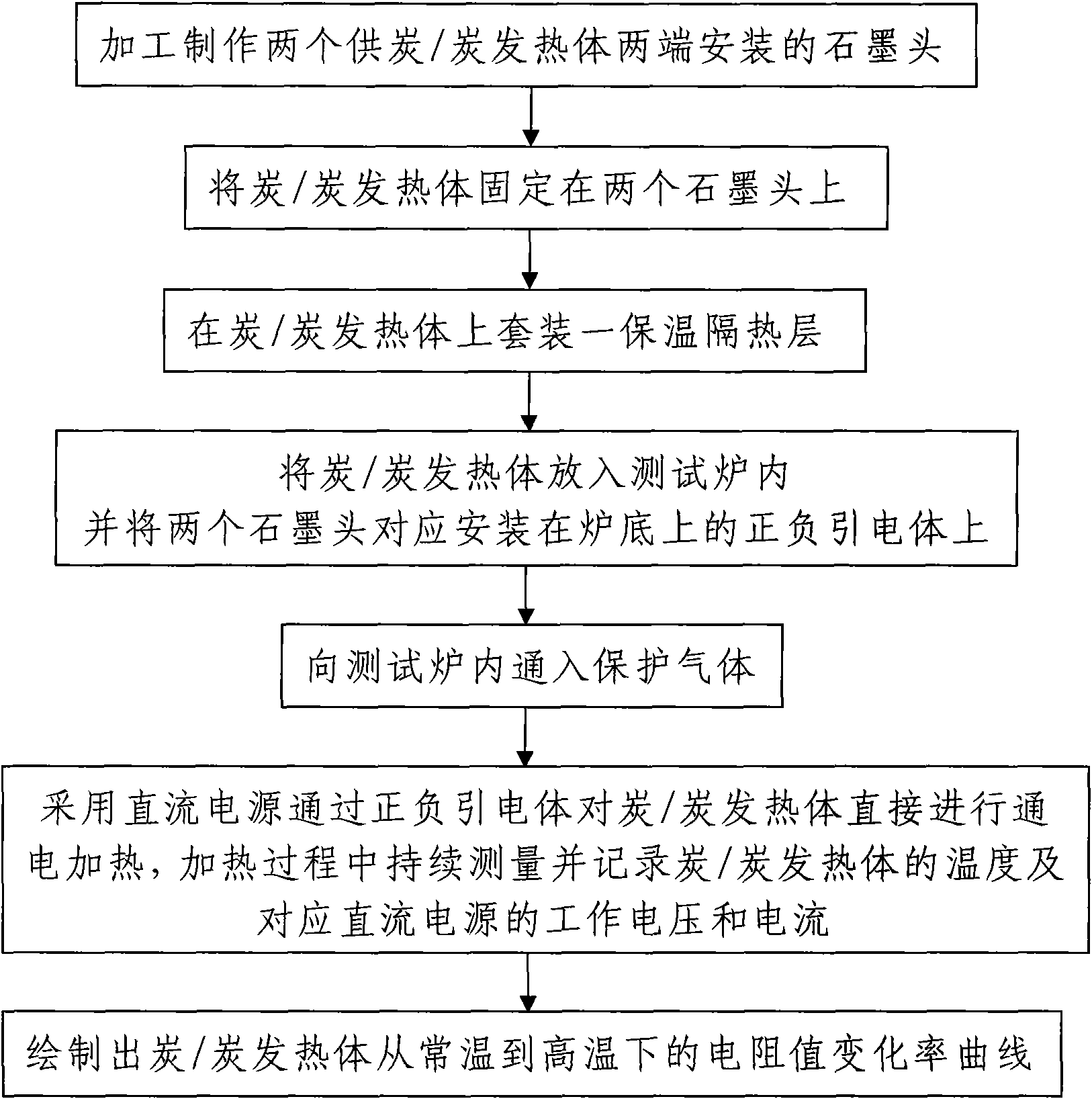

[0037] Such as figure 1 , figure 2 and image 3 As shown, the method for direct heating test charcoal / charcoal heating element high temperature resistance of the present invention comprises the following steps:

[0038] Step 1. Select the structure of the test furnace according to the wall thickness, outer opening diameter and length of the U-shaped charcoal / charcoal heating element 1 to be tested, and process and manufacture two with the same structure and opposite positions for installation at both ends of the charcoal / charcoal heating element 1. Graphite head 2. The upper part of the graphite head 2 is correspondingly provided with an installation port 1 for the end of the charcoal / charcoal heating element 1 to be installed, and its bottom is provided with an installation port 2 5 for the installation of the lead electrode 11 . The inner middle part of the graphite head 2 is provided with a notch 6 extending from the second installation opening 5 to the outside of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com