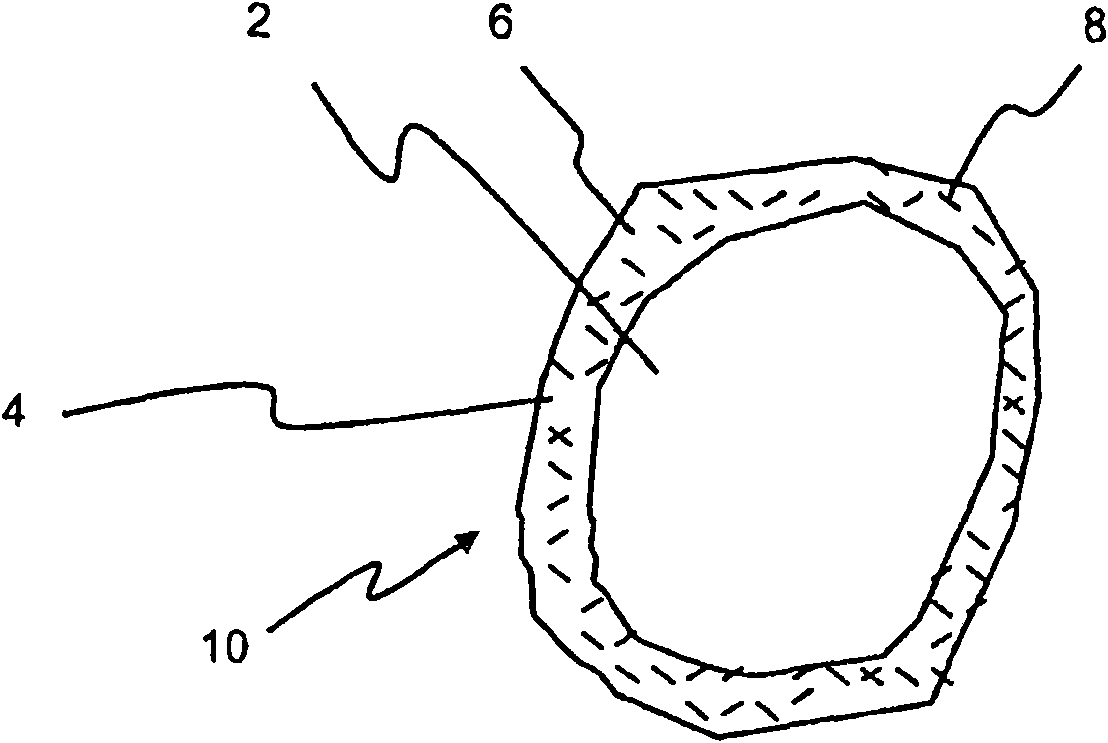

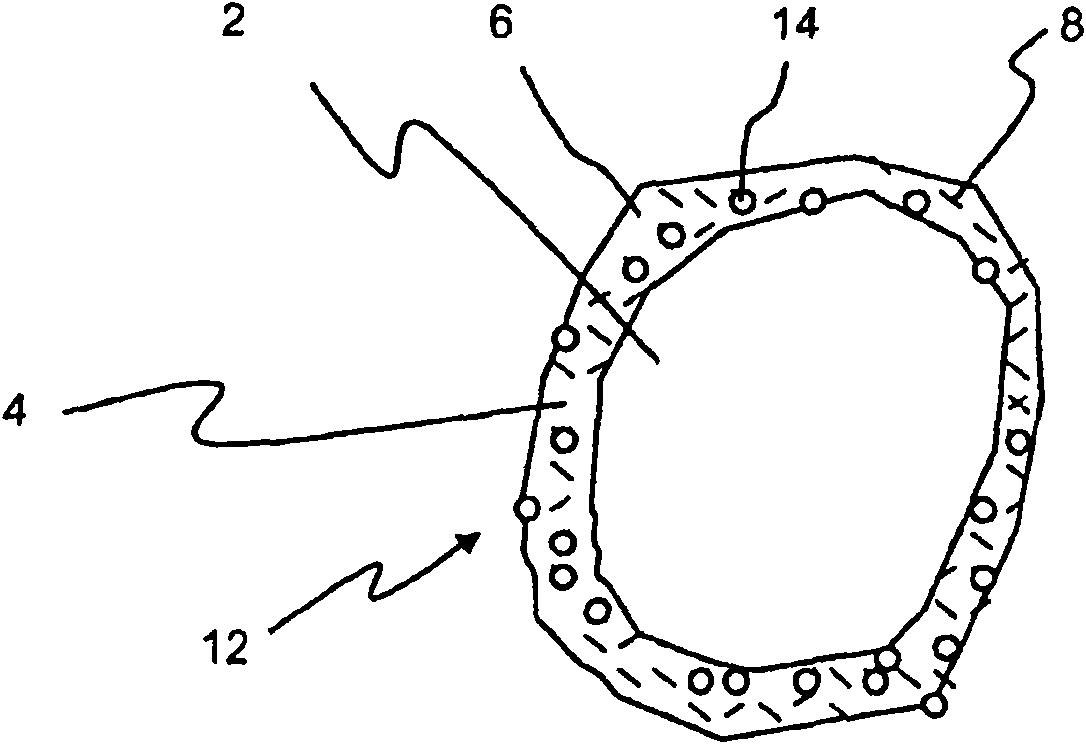

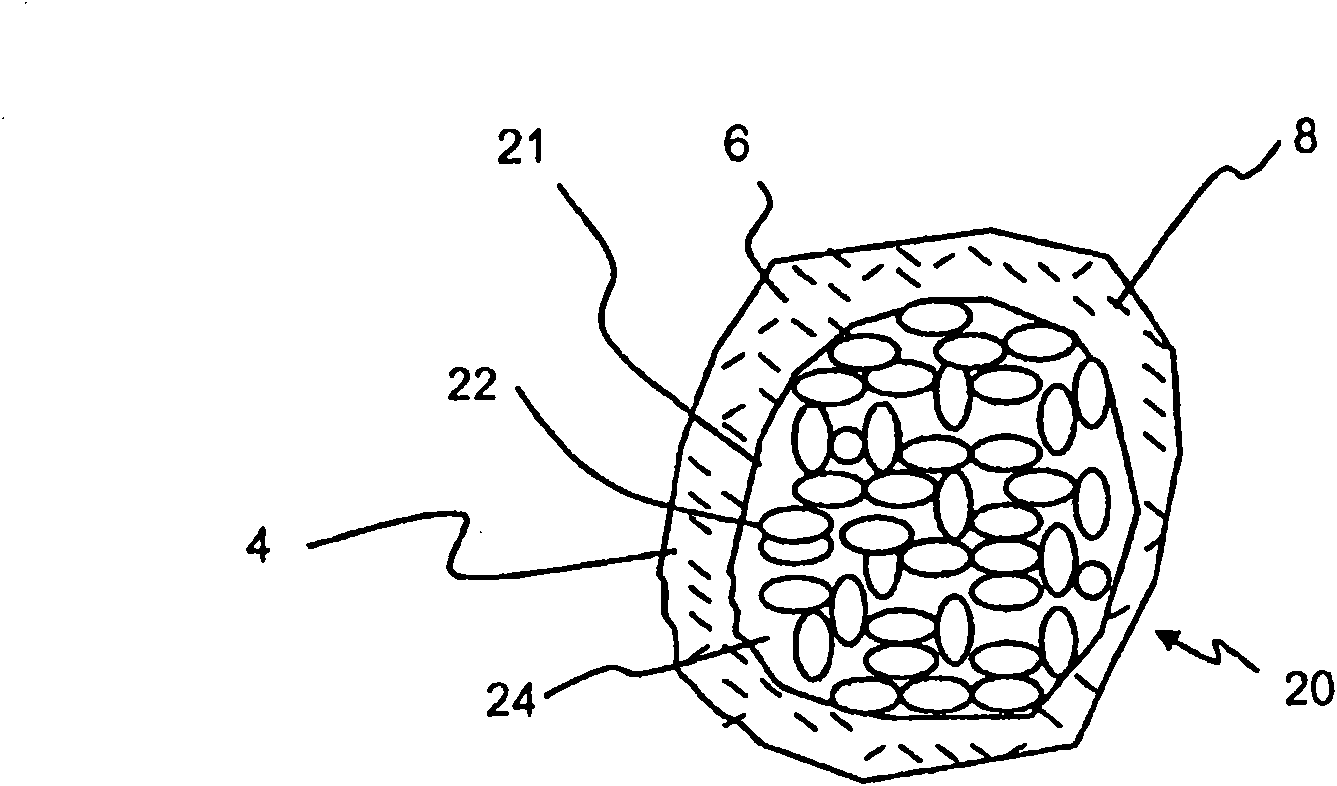

Low temperature coated particles for use as proppants or in gravel packs, methods for making and using the same

A particle, coating technology, applied in chemical instruments and methods, coatings, powder coatings, etc., to achieve freight savings, emissions minimization, and energy savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0259] This test was performed to determine the properties of the coated particles of the present invention. The coating cycle is as follows. Will 1000 grams 12 / 18 medium density ceramic particles were added to a Hobart laboratory mixer at room temperature. Then start the mixer agitator. Then 0.8 grams of A1100 (aminopropyltriethoxysilane) was added and the timer was started (0:00 minutes). After 30 seconds, 10.0 gms EX262E (liquid resole, phenol-formaldehyde liquid resole) was added. When the timer was at 2 minutes, 18.4 grams of SD909A novolac powder (with 15% hexamethylenetetramine) was added with continued stirring (about 2.4% total organics on the granules). When the timer was at 12 minutes, the material was free flowing and removed from the mixer. The product was then tested for 24 hour UCS bond strength at 1000 psi and 200°F and found 590 psi.

Embodiment 2

[0261] This test was performed to determine the properties of the coated particles of the present invention. The coating cycle is as follows. Will 1000 grams 12 / 18 medium density ceramic particles were added to a Hobart laboratory mixer at room temperature. Then start the mixer agitator. Then 0.8 grams of A1100 (aminopropyltriethoxysilane) was added and the timer was started (0 minutes). After about 30 seconds, 10.0 gms EX262E (liquid resole) was added. When the timer is at 2 minutes, add 33.2 grams of SD672D powder (novolac, hexamethylenetetramine free) with continued stirring (about 4% total organics on the granules); SD672D powder has + / -100 Purpose granularity. When the timer was at 12 minutes, the material was free flowing and removed from the mixer. The product was then tested for 24 hour UCS bond strength at 1000 psi and 200°F and found 1075 psi.

Embodiment 3

[0263] A curable resin coating was formed by adding 0.4 grams of coupling agent (A-1100 silane) to 1 kilogram of substrate under constant stirring. Silane was followed by liquid resole resin (OWR-262E) from Hexion Specialty Chemicals, Inc., Louisville, Kentucky, 15 seconds into the cycle. Powdered novolak FD900-A (with 7% hexamethylenetetramine for preparation of samples C, D, each from Hexion Specialty Chemicals, Inc., Louisville, Kentucky) was then added at 1 minute on cycle time. and G), or powdered novolac SD-909A (with 15% hexamethylenetetramine for the preparation of samples A, B, E and F). The material was mixed for an additional 4 minutes and discharged from the mixing device. Using the procedure described above, the performance changes were analyzed while evaluating alternative resins, resin content, particle size, and substrates. The concentration of hexamethylenetetramine in the novolac powders therefore varied from 7% to 15% depending on the powder used in each f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com