Biological activating solution for surface of magnesium alloy and application thereof

A bioactivation, magnesium alloy technology, used in bone implants, medical science, prostheses, etc., can solve problems such as loss of advantages and biological activity, and achieve the effect of promoting cell adhesion, cell adhesion, and accelerating bone healing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

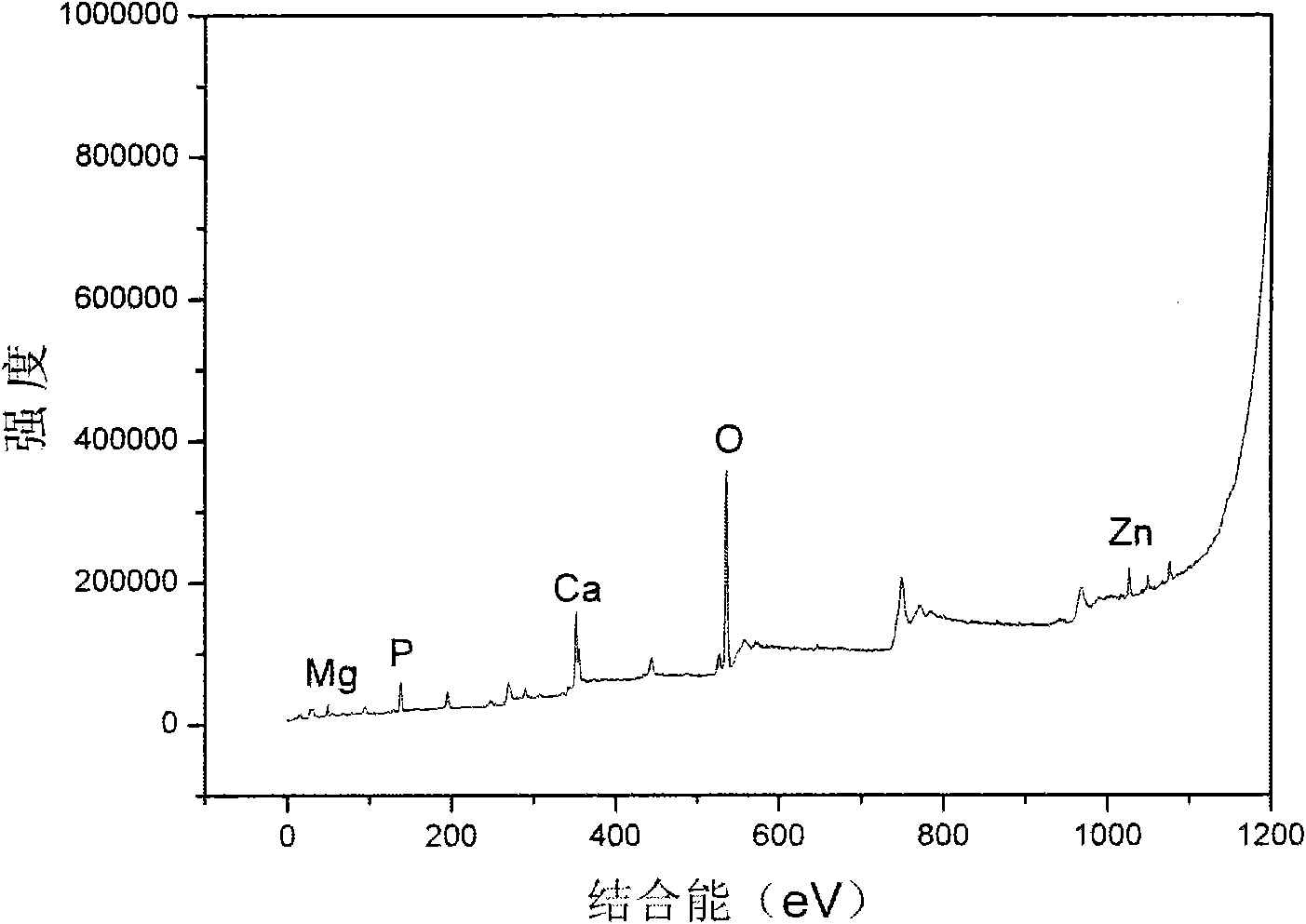

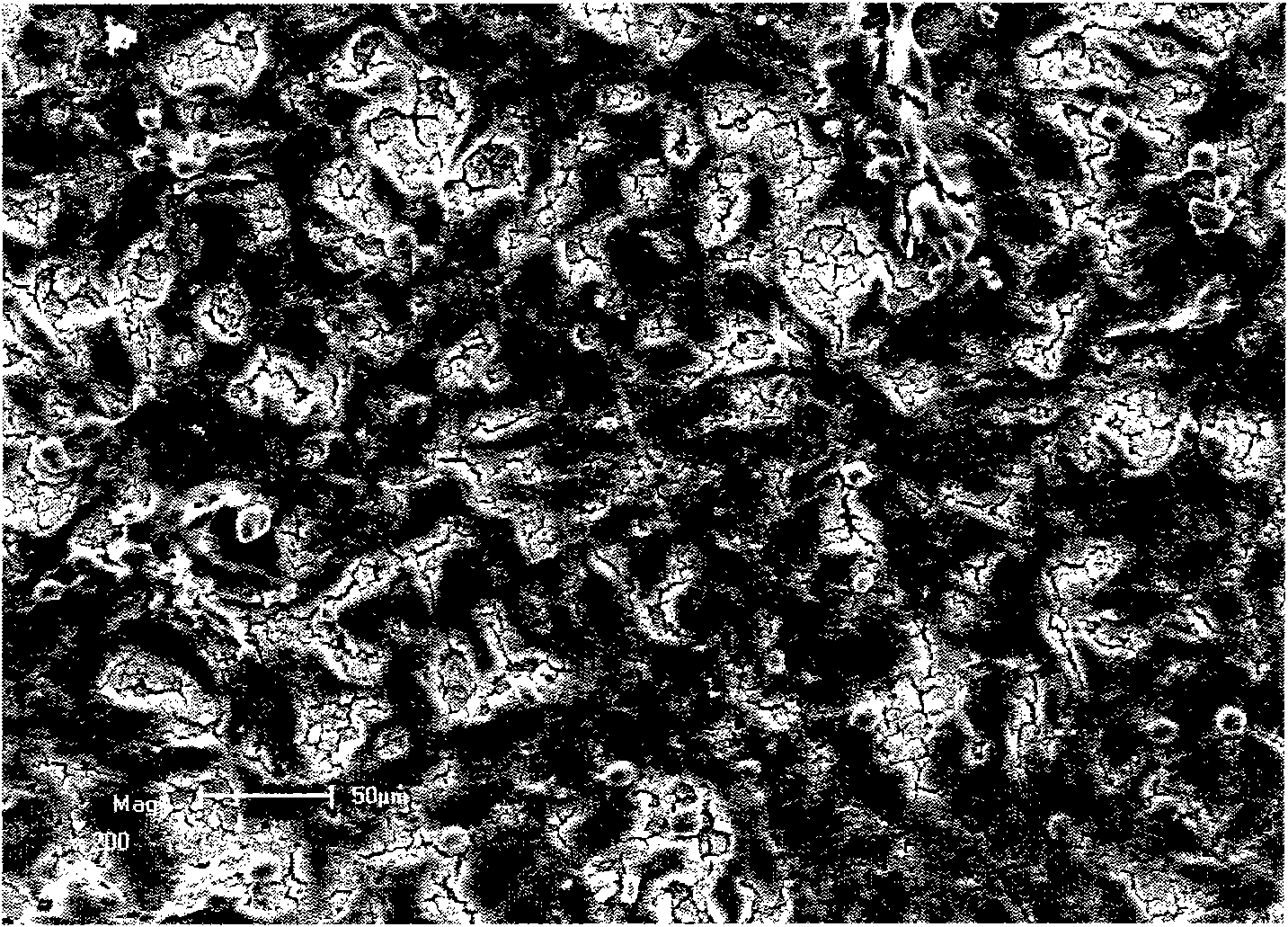

[0031] The magnesium alloy used is Mg-Mn-Zn, and the alloy grade is MZ11.

[0032] 1. The alloy sample after conventional grinding and degreasing was treated with 2% H 3 PO 4 Activation in the solution for 5 seconds, the volume of the phosphoric acid solution in this embodiment and the surface area ratio of the magnesium alloy to be activated are 110mL / cm 2 , rinse with distilled water and dry before use.

[0033] 2. Take an appropriate amount of distilled water, and use the following ingredients: H 3 PO 4 7g / L, CaH 2 PO 4 7.47g / L, ZnH 2 PO 4 1.60g / L, NaNO 3 2g / L, NaNO 2 3g / L solution, the molar ratio of calcium ions to zinc ions in the solution of this example is about 6:1, and the pH is adjusted to 4.0.

[0034]3. Heat the prepared treatment solution to 60°C, then put the activated alloy sample into the treatment solution and soak for 5 minutes, take it out, wash it with distilled water and dry it, the thickness of the obtained bioactive coating on the surface of t...

Embodiment 2

[0038] The difference from Example 1 is:

[0039] The magnesium alloy used is Mg-Mn-Zn, and the alloy grade is MZ11.

[0040] 1. Put the polished and degreased alloy sample in 2% H 3 PO 4 Activation in the solution for 5 seconds, the volume of the phosphoric acid solution in this embodiment and the surface area ratio of the magnesium alloy to be activated are 120mL / cm 2 , rinse with distilled water and dry before use.

[0041] 2. Take an appropriate amount of distilled water, according to the following ingredients: H 3 PO 4 8g / L, CaH 2 PO 4 8.00g / L, ZnH 2 PO 4 1.02g / L, NaNO 3 2g / L, NaNO 2 3g / L solution, the molar ratio of calcium ions to zinc ions in the solution of this example is 10:1, and the pH is adjusted to 3.5.

[0042] 3. Heat the prepared treatment solution to 50°C, then put the activated alloy sample into the treatment solution and soak for 20 minutes, take it out, wash it with distilled water and dry it, the thickness of the obtained bioactive coating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com