Method for synthesizing oriented MFI type molecular sieve membrane by means of microwave heating

A technology of microwave heating and molecular sieve, which is applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of high preparation cost and complicated operation steps, and achieve the effects of uniform grain size, continuous film layer and shortened synthesis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

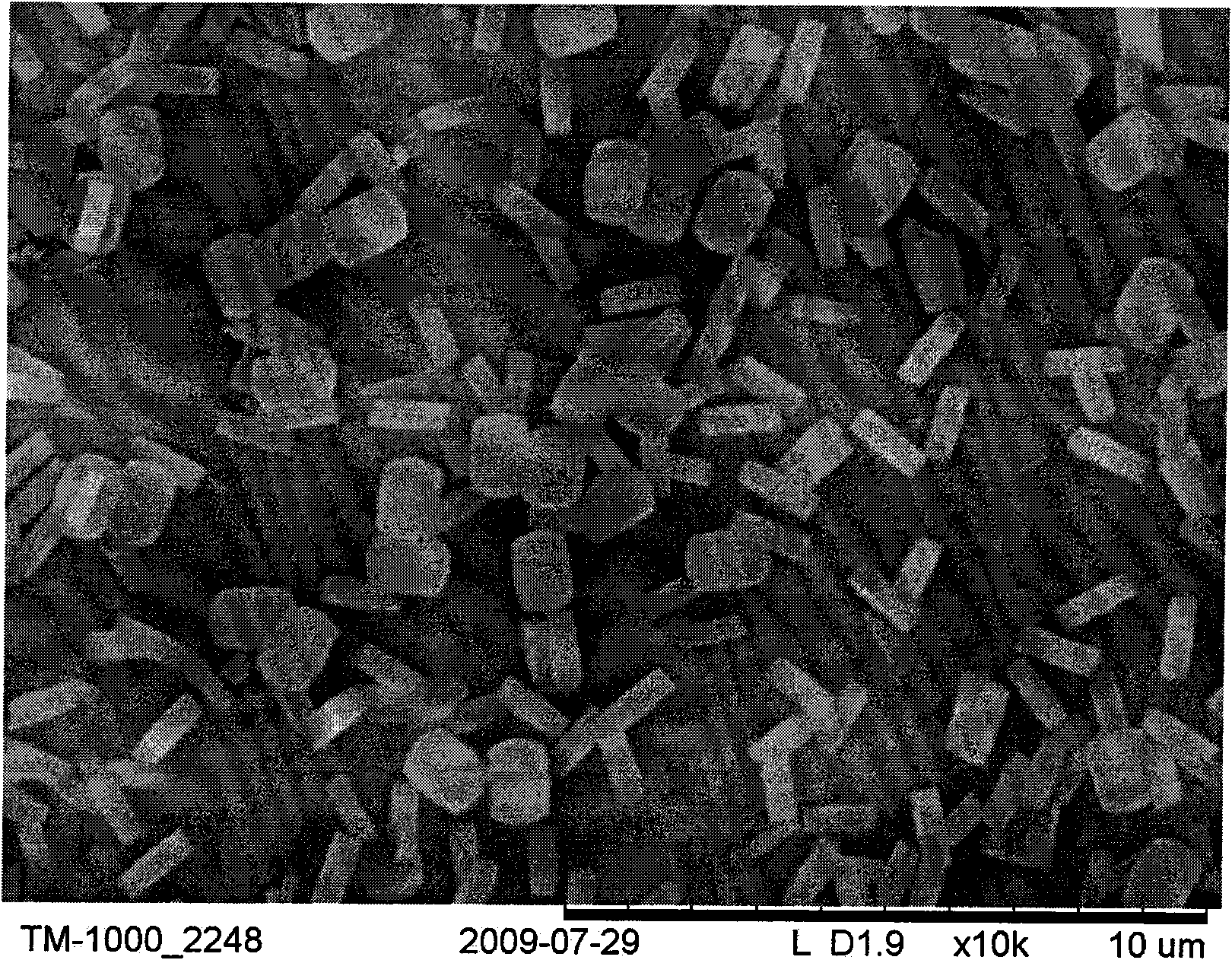

[0026] Example 1 Synthesis of Oriented MFI Molecular Sieve Membrane by Traditional Heating Method

[0027] The molar ratio is ethyl orthosilicate: tetrapropyl ammonium hydroxide: water = 1: 0.32: 165 40 milliliters of synthesis solution was stirred at room temperature for 4 hours to obtain a clear and transparent solution, and then this synthesis solution was supported by a stainless steel sheet Put the body together in a 100 ml synthesis kettle with a polytetrafluoroethylene liner, then put the sealed synthesis kettle into a blast oven at 165°C for crystallization for 2 hours, and finally take out the crystallized synthesis kettle After quenching to room temperature, the support body was taken out, washed with deionized water and dried. The scanning electron microscope pictures of the dried molecular sieve membranes are as follows: figure 1 As shown, the obtained molecular sieve membrane is a continuous b-axis oriented MFI type molecular sieve membrane.

Embodiment 2

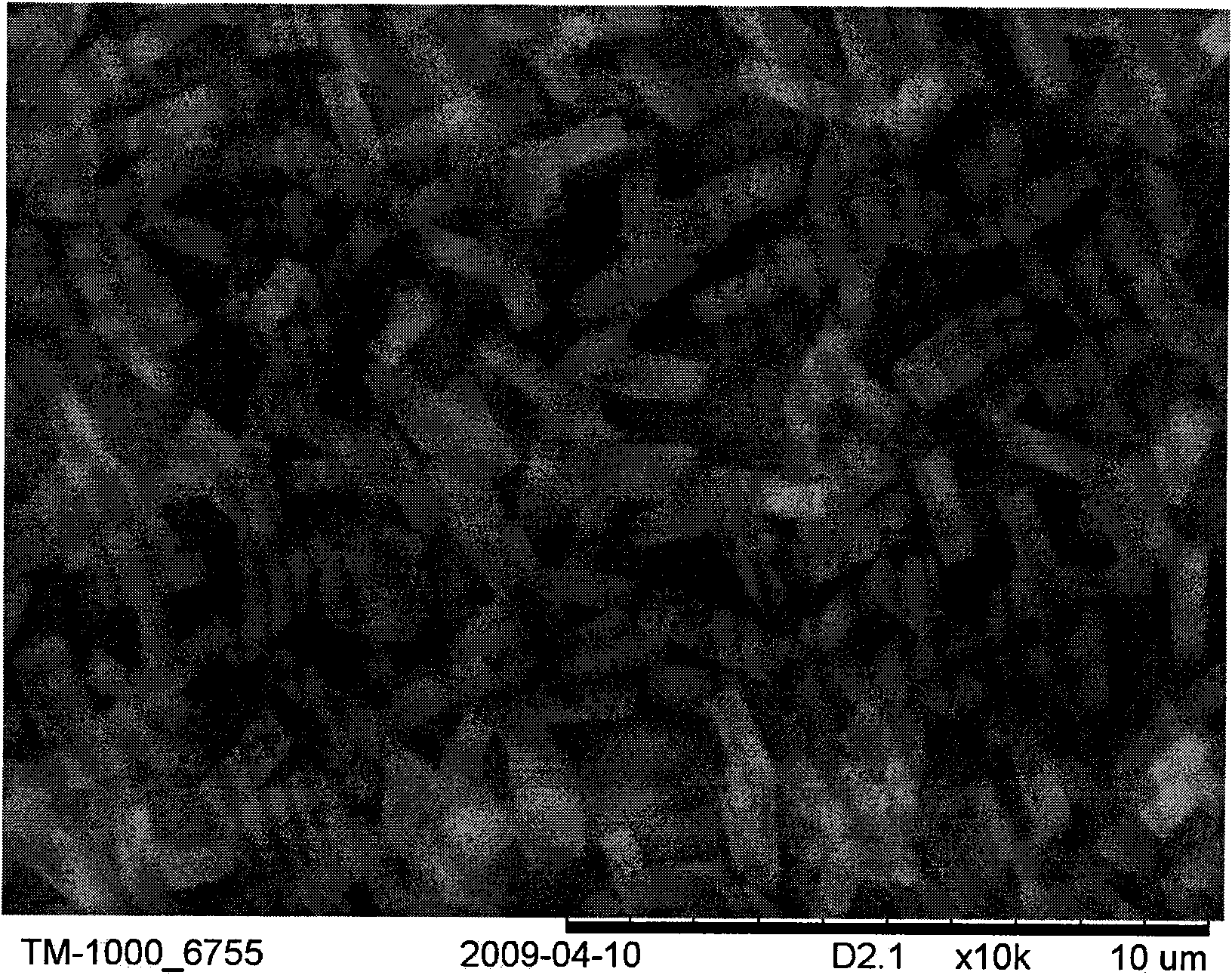

[0028] Example 2 Synthesis of Oriented MFI Molecular Sieve Membrane by Aging at Room Temperature and Microwave Heating

[0029] Stir 20 milliliters of synthetic solution with a molar ratio of tetrapropylammonium hydroxide: water = 1:0.32:165 at room temperature for 4 hours to obtain a clear and transparent solution, and then stir and age at room temperature for 20 hours , and then put the synthetic solution together with the stainless steel sheet support into a 70 ml synthesis kettle with a polytetrafluoroethylene liner, and then put the sealed synthesis kettle into a microwave oven and raise the temperature to 165 ° C for 35 minutes to crystallize. Finally, the crystallized synthesis kettle was naturally cooled to room temperature, and then the support was taken out, washed with deionized water, and then dried. The scanning electron microscope pictures of the dried molecular sieve membranes are as follows: figure 2 As shown, the obtained molecular sieve membrane is a contin...

Embodiment 3

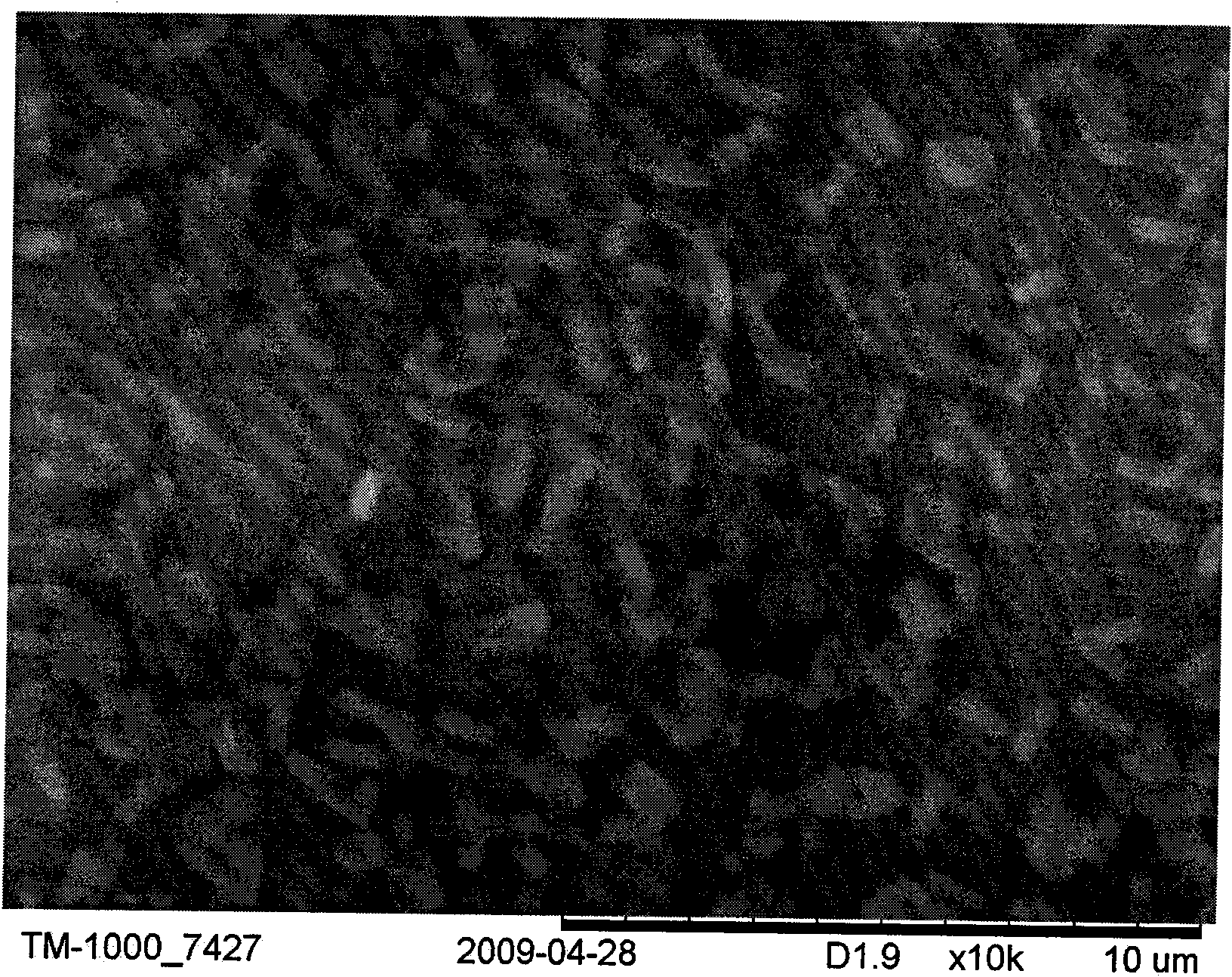

[0030] Example 3 Synthesis of Oriented MFI Molecular Sieve Membrane by Aging at Room Temperature and Microwave Heating

[0031] Same as Example 2, aging with stirring at room temperature for 50 hours. From the scanning electron microscope picture of the dried molecular sieve membrane, it can be seen that the obtained molecular sieve membrane is a continuous b-axis oriented MFI type molecular sieve membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com