Nano material for CA mortar

A nano-material and mortar technology, which is applied in the field of manufacturing auxiliary materials for cement asphalt mortar, can solve the problems affecting the strength and other properties of the CA mortar layer, easy delamination, poor compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

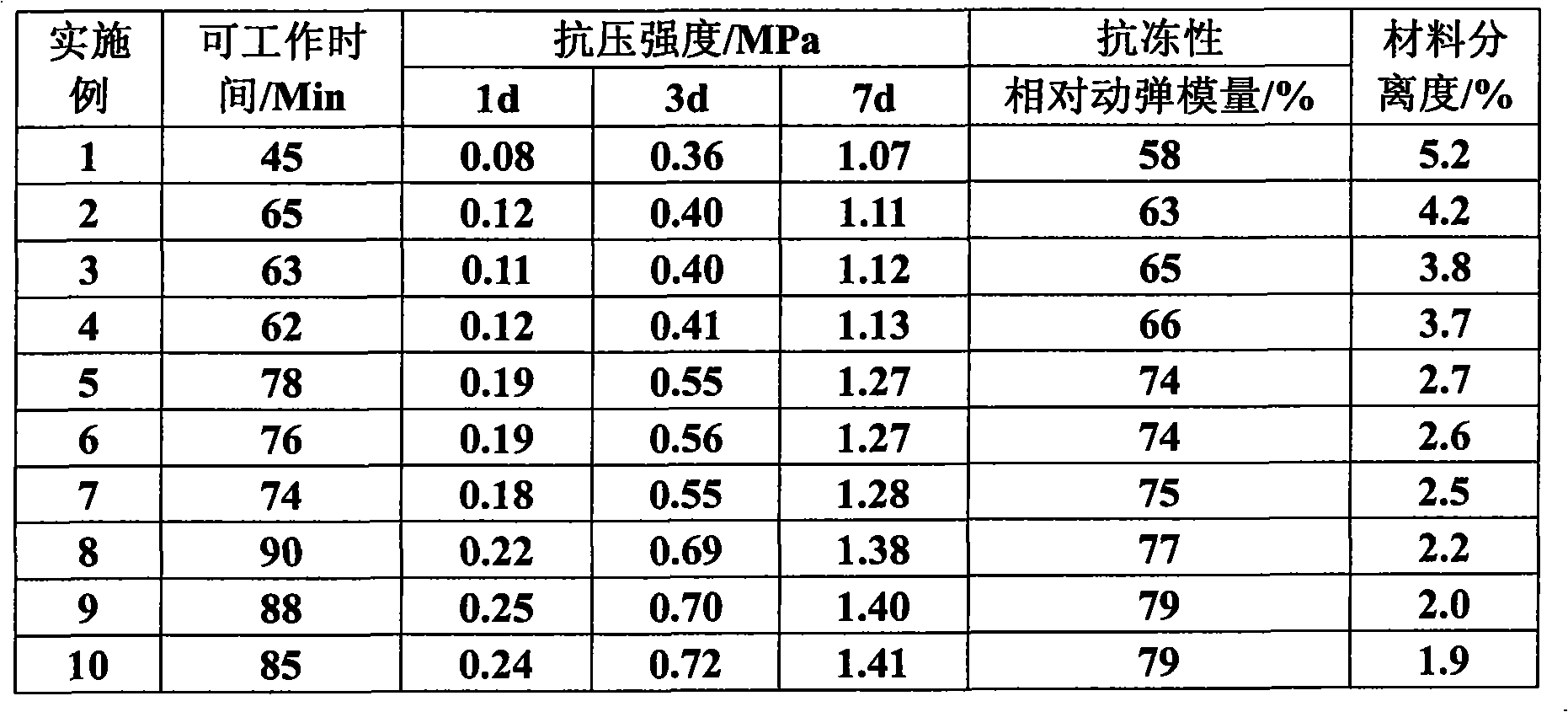

Examples

Embodiment 1

[0010] Example 1 (Comparative example of prior art): take 100 parts of cement, 220 parts of fine aggregate, 0.55 part of defoaming agent, 10 parts of expansion agent, 180 parts of asphalt emulsion, and 25 parts of water, and test the sample after mixing and stirring .

Embodiment 2

[0011] Example 2: Take 100 parts of cement, 220 parts of fine aggregates, 0.55 parts of defoamer, 10 parts of expansion agent, nanomaterials (nano-SiO 2 : Nano-CaCO 3 : 1 part of zinc oxide = 45:50:5), 180 parts of asphalt emulsion, and 25 parts of water. After mixing and stirring, the samples were tested.

Embodiment 3

[0012] Example 3: Take 100 parts of cement, 220 parts of fine aggregate, 0.55 parts of defoamer, 10 parts of expansion agent, nanomaterials (nano-SiO 2 : Nano-CaCO 3 : 1 part of zinc oxide = 38:57:5), 180 parts of asphalt emulsion, and 25 parts of water, and the samples were tested after mixing and stirring.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com