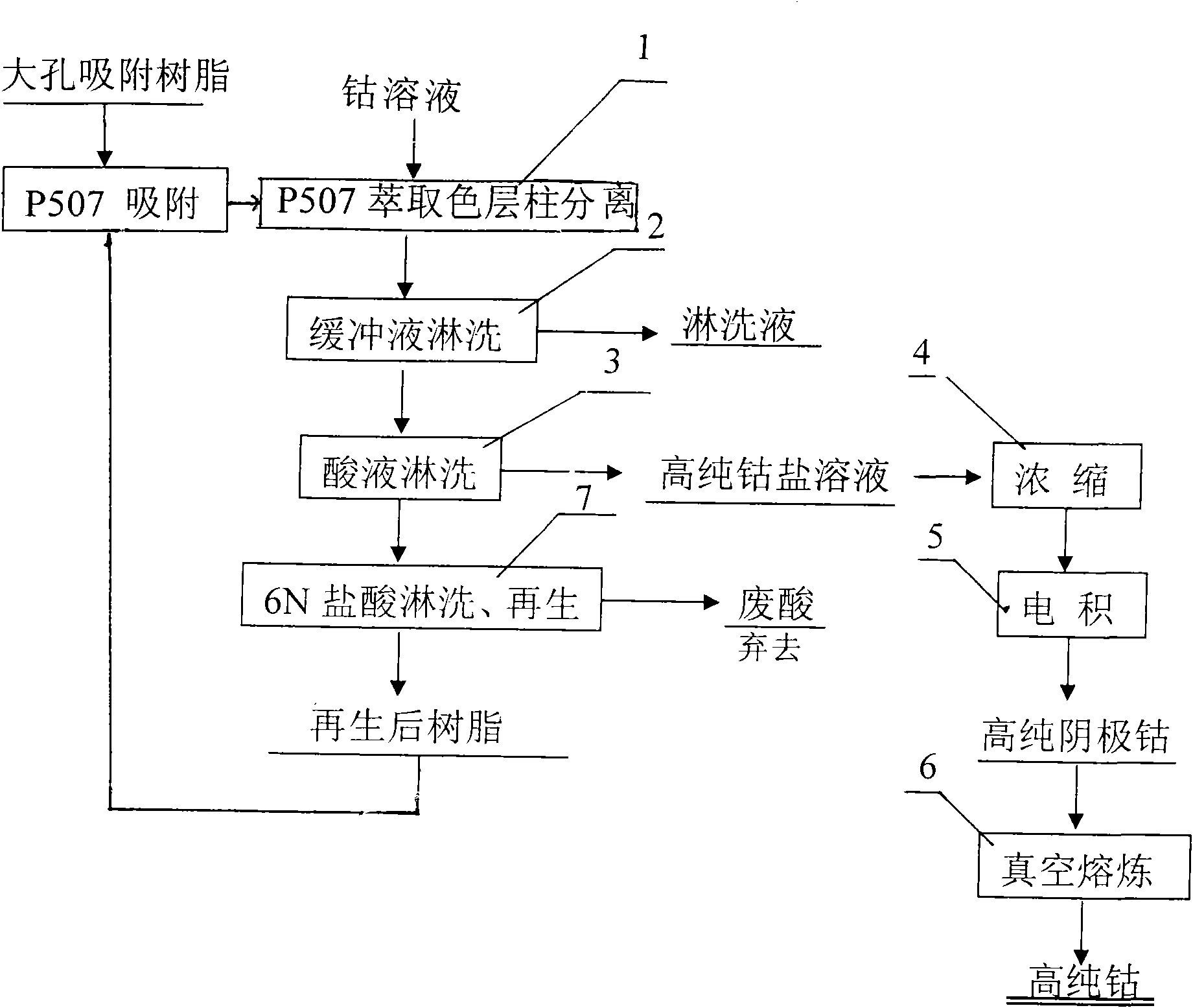

Process method for separating and purifying cobalt solution by extraction chromatography

A chromatographic separation and process method technology, applied in the field of producing high-purity cobalt solution, can solve the problems of difficult pH value control in the column, low cobalt direct yield, low efficiency, etc., and achieves reduction of irritating odor, high product quality, The effect of improving the rinsing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Get 10 kilograms of water-containing macroporous adsorbent resin (buy from the market, brand HPD-100, its relevant parameters: 1, particle size: (particle diameter 0.3-1.2mm) ≥ 90%); 2, average pore diameter: 85-90 ° A; specific surface 650-700m 2 / g; adsorption flow rate: 1-4BV / h; desorption flow rate: 0.6-2BV / h; desorbent: ethanol or ethanol aqueous solution; desorbent dosage: 2-3BV) into the aqueous solution, add 2 kg of P507 extractant, Carry out adsorption treatment under the condition of stirring, prepare the extraction resin of 34%P507 after filtration, pack into the diameter and be 80mm, be long the plexiglass column of 850mm, be assembled into P507 extraction resin column, its empty volume is about About 400ml.

[0037] Add 5 liters of cobalt chloride feed liquid, wherein the cobalt concentration is 60 g / L, the pH value of the feed liquid is 4.5, and the P507 extraction resin column is rinsed until the pH value of the eluate changes from 1.7 to 3.5 and ends. ...

Embodiment 2

[0042] The test operation method is the same as in Example 1. Prepare 50% P507 extraction resin. Add 5 liters of cobalt sulfate feed solution, wherein the cobalt concentration is 80 g / L, the pH value of the feed solution is 4, and the P507 extraction resin column is rinsed until the pH value of the eluate changes from 1.7 to 3.

[0043] Then use the HAc-NaAc buffer solution with a pH value of 3 to wash the loaded P507 extraction resin, control the flow rate to be 1.2 times / h of the chromatographic column void volume, when the eluate volume is 4 times of the chromatographic column void volume When the acidity is 1 mol / L sulfuric acid solution is used instead to quickly elute the cobalt ions adsorbed by the chromatography column.

[0044] Finally, regenerate and rinse the P507 extraction resin column. The regeneration solution is 6 mol / L hydrochloric acid solution. When the volume of the eluate is 4 times the void volume of the chromatographic column, use deionized water to rin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com