Plasma display panel provided with triangular pixel structure and driven according to sub-row branch fields

A pixel structure and plasma technology, applied in static indicators, cold cathode tubes, instruments, etc., can solve the problems of reduced efficiency, halved luminous efficiency, reduced display brightness and luminous efficiency, etc., to improve product qualification rate, The effect of reducing the difficulty of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

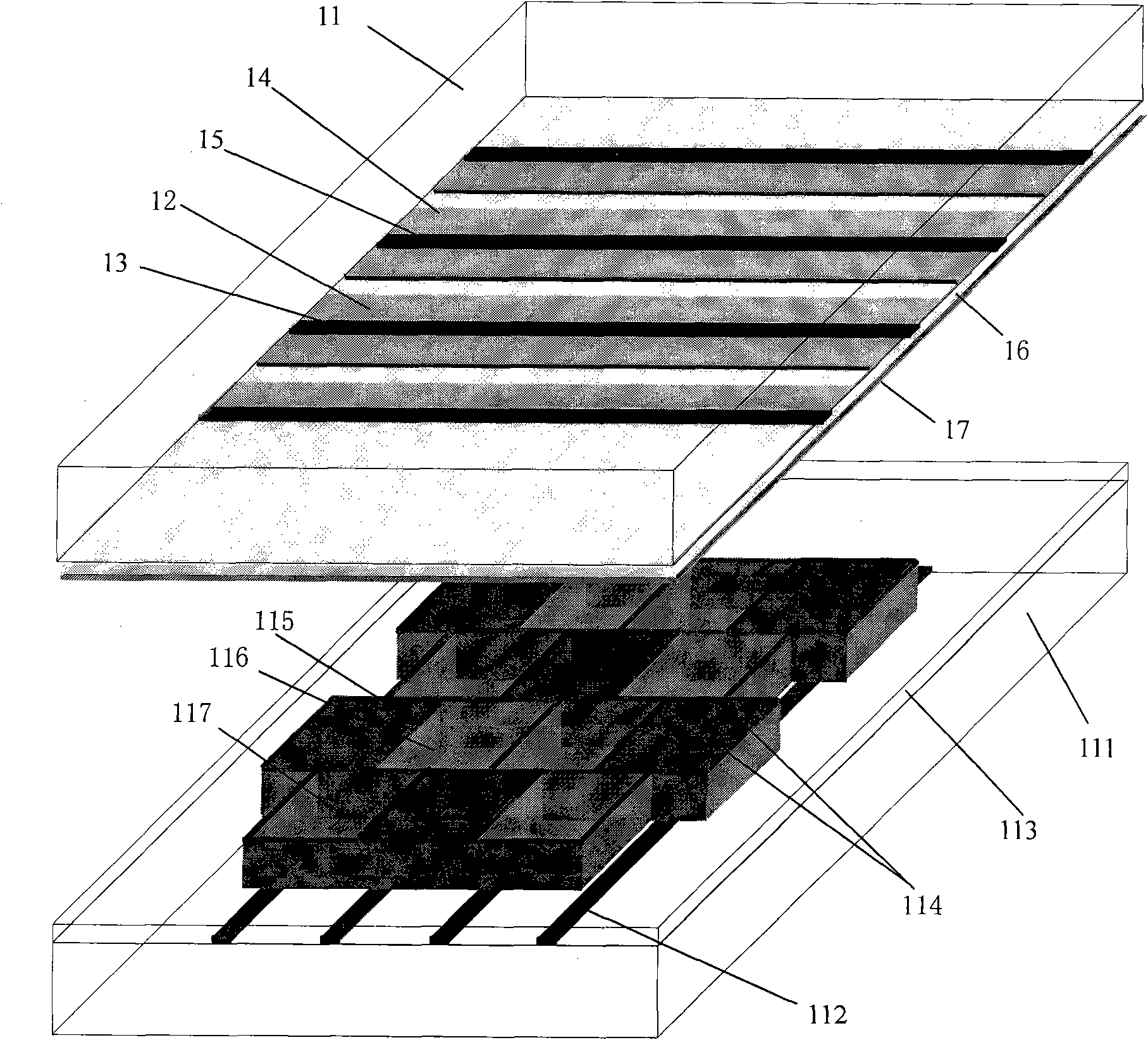

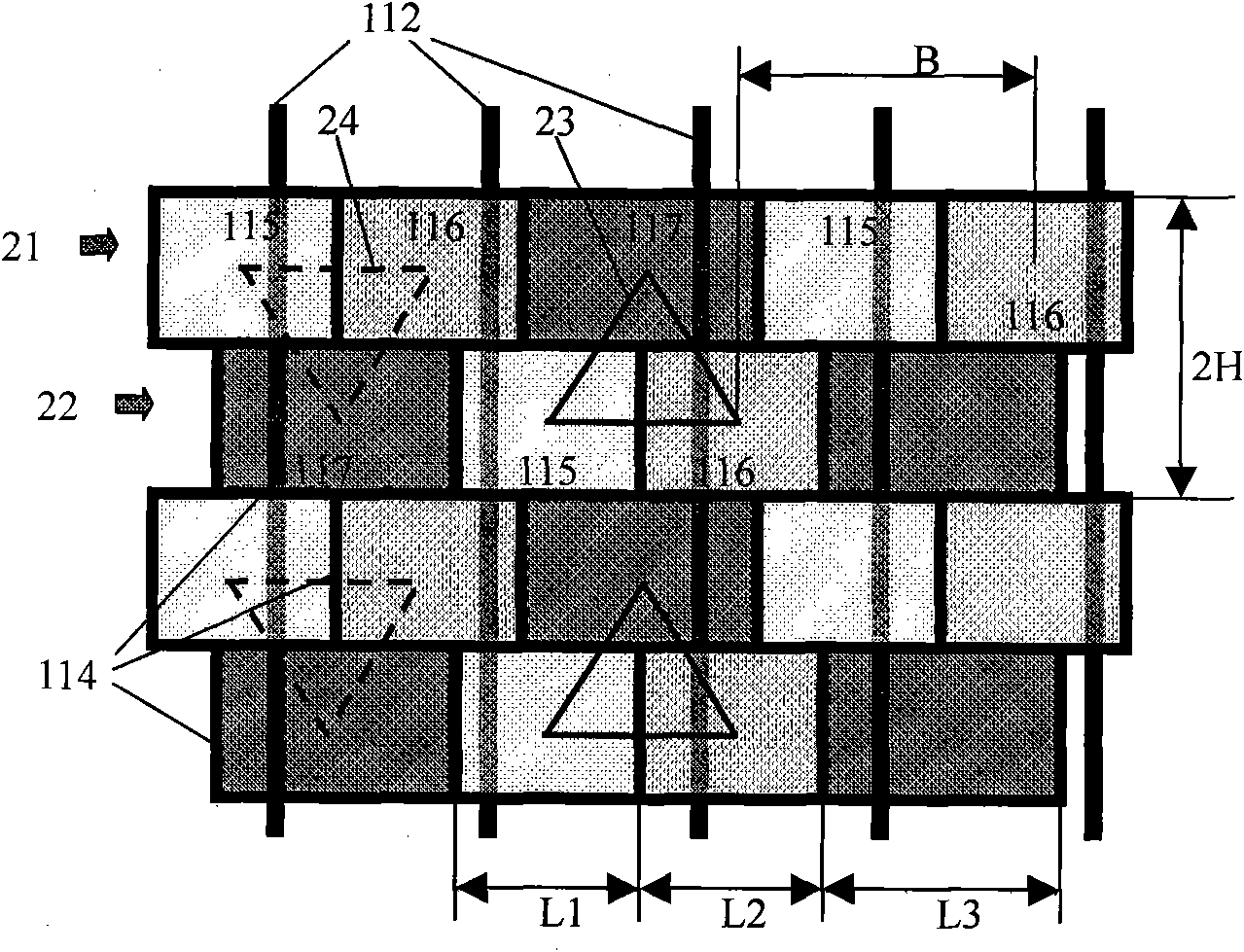

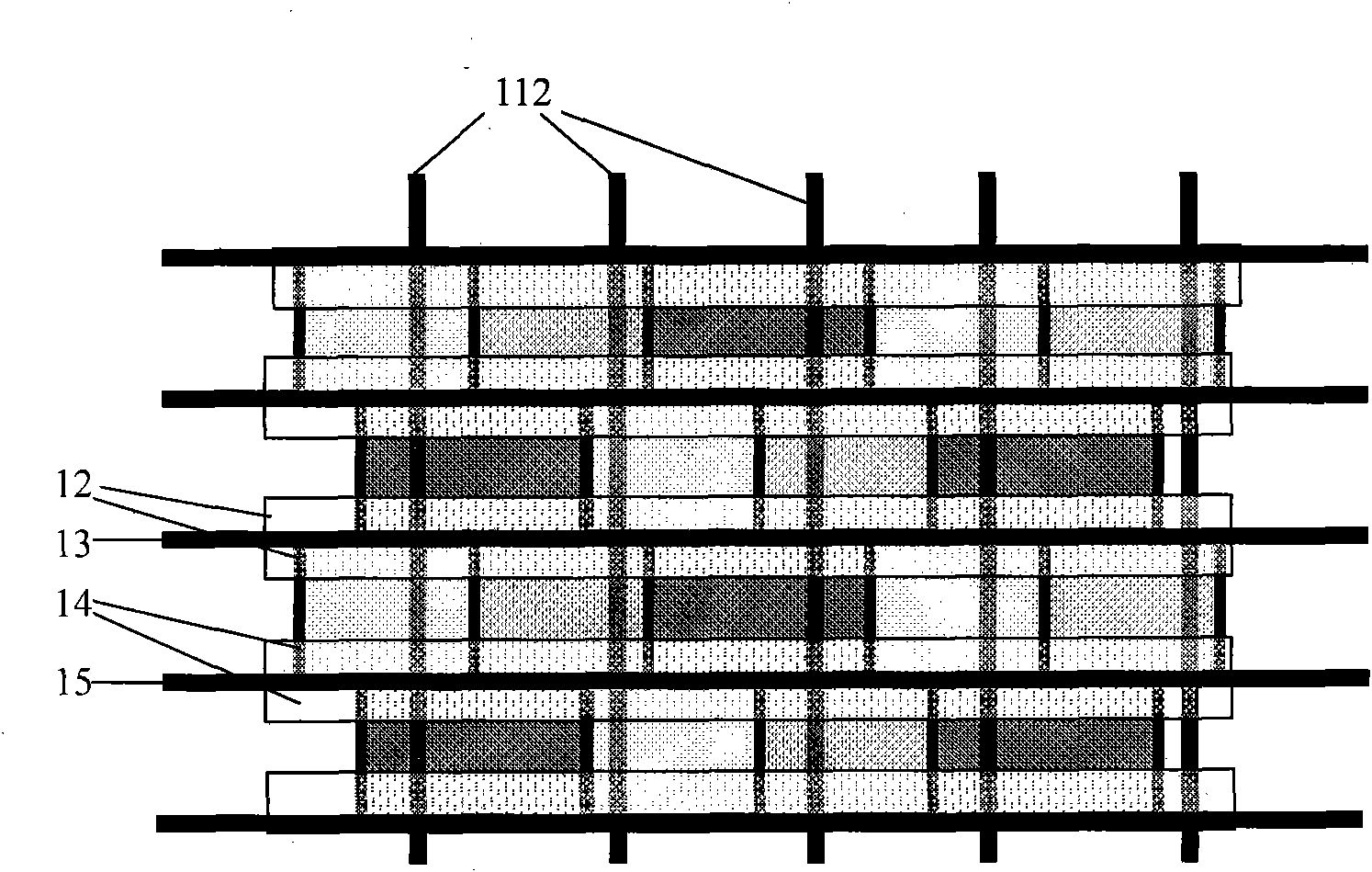

[0034] 42-inch high-definition display screen with 1920×1080 pixels and a sub-pixel size of 320μm×240μm. On the rear glass, use conventional screen printing to prepare strip-shaped linear A electrodes and the dielectric layer of the rear plate, and use sandblasting and sintering processes to prepare rectangular barriers. The thickness of the barrier is 30 μm, and the height is 110 μm. The effective area of the sub-pixel is 290 μm×210 μm. ; In order to coat three-primary-color phosphors with a screen printing method, three primary-color rectangular sub-pixels are obtained by printing three times to form triangular and inverted triangular pixels. The transparent and conductive X electrodes and Y electrodes on the front plate are strip-shaped structures, which are prepared by standard photolithography and etching techniques. The gap between the X electrodes and Y electrodes is 130 μm. The dielectric layer of the front plate was prepared by screen printing technology, and the di...

Embodiment 2

[0036] 42-inch high-definition display screen with 1920×1080 pixels and a sub-pixel size of 320μm×240μm. On the rear plate glass, the A electrode with a folded line structure and the dielectric layer of the rear plate were prepared by conventional screen printing, and the rectangular barrier was prepared by sandblasting and sintering. The thickness of the barrier was 30 μm, and the height was 110 μm. ; In order to coat three-primary-color phosphors with a screen printing method, three primary-color rectangular sub-pixels are obtained by printing three times to form triangular and inverted triangular pixels. The transparent and conductive X electrodes and Y electrodes on the front plate are strip-shaped structures, which are prepared by standard photolithography and etching techniques. The gap between the X electrodes and Y electrodes is 130 μm. The dielectric layer of the front plate was prepared by screen printing technology, and the dielectric protection layer of magnesium o...

Embodiment 3

[0038] 42-inch high-definition display screen, 1920×1080 pixels, available sub-pixel size is 320μm×240μm. On the rear glass, the electrode and the dielectric layer of the sinusoidal structure A are prepared by conventional screen printing, and the rectangular barrier is prepared by sandblasting and sintering. The thickness of the barrier is 30 μm, and the height is 110 μm. 210 μm; in order to coat three-primary-color phosphors by screen printing, three primary-color rectangular sub-pixels are obtained by printing three times, forming triangular and inverted triangular pixels. The transparent and conductive X electrodes and Y electrodes on the front plate are strip-shaped structures, which are prepared by standard photolithography and etching techniques. The gap between the X electrodes and Y electrodes is 130 μm. The dielectric layer of the front plate was prepared by screen printing technology, and the dielectric protection layer of magnesium oxide with a thickness of 700 nan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com