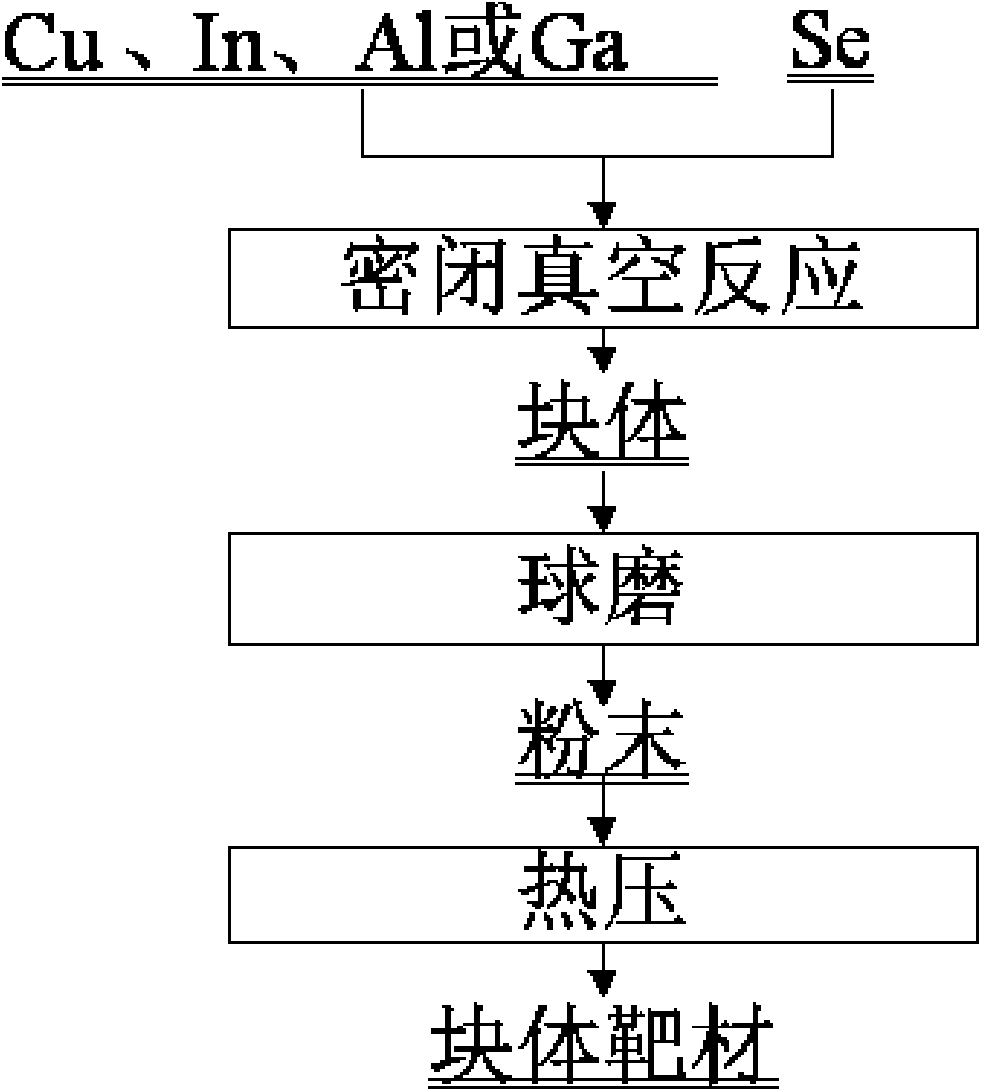

Preparation method of selenide material for absorbing layer of thin film solar cell

A technology of solar cells and selenides, which is applied in the manufacture of circuits, electrical components, and final products. It can solve the problems of unreasonable preparation process design, difficulty in forming integrated alloys, and large density differences. The ratio of elements is easy to control, The effect of low cost and accurate ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Put Cu powder and Se block with a purity of 99.995% into an autoclave lined with alumina ceramics in a molar ratio of Cu:Se=2:1 after 400g, and put them into an autoclave lined with alumina ceramics. -3 Close the autoclave under Pa vacuum condition.

[0021] Place the autoclave in a furnace that is cooled by nitrogen circulation and the furnace wall is cooled by circulating water. The temperature in the furnace is constant temperature gradient, that is, the temperature is adjusted to a temperature higher than the melting point of the material at a heating rate of 10°C / min. 1200°C is divided into 5 stages of temperature rise and constant temperature. The temperature of each temperature stage is: the final adjusted temperature higher than the melting point of the material / 5+1, that is, the 5 stages of constant temperature are 200°C, 400°C, 600°C, and 800°C. , 1000°C, and the constant temperature time is 2 hours respectively, and finally adjusted to 1200°C for 2 hours, so ...

Embodiment 2

[0024] Put the Cu powder and Se block with a purity of 99.98% into a reaction kettle lined with alumina ceramics and fill it with 8×10 4 Pa argon to seal the reactor.

[0025] Place the reaction kettle filled with argon in the furnace for gradient temperature rise and constant temperature, that is, at a temperature rise rate of 15°C / min, according to the final temperature adjusted to 1210°C higher than the melting point of the material, it is divided into 5 stages of temperature rise and constant temperature, each temperature The temperature of the section is: -12+℃, the temperature finally adjusted to be higher than the melting point of the material / 5+1, that is, the constant temperature of the five sections are 190℃, 380℃, 570℃, 760℃, 950℃, and the constant temperature time: 2.5 Hours, and finally adjusted to 1210 ° C temperature conditions for 2.5 hours, so that it was slowly cooled to room temperature within 8 hours. The prepared block was taken out from the reactor and t...

Embodiment 3

[0028] Put In block and Se block with a purity of 99.8% into the autoclave lined with zirconia ceramics after the molar ratio of In:Se=2:3 is 500g, at 6.2×10 -3 Close the autoclave under Pa vacuum condition.

[0029] The autoclave closed under vacuum is placed in a furnace cooled by nitrogen circulation, and the furnace wall is cooled by circulating water. The temperature in the furnace is constant temperature gradient, that is, at a heating rate of 20°C / min, according to the final adjustment to a temperature higher than The temperature of the melting point of the material is 950°C, which is divided into 4 stages of temperature rise and constant temperature. The temperature of each temperature stage is: 10°C + the final adjusted temperature higher than the melting point of the material / 4+1, that is, the 4 stages of constant temperature are 200°C and 400°C respectively. °C, 600 °C, 800 °C, the constant temperature time is 3 hours respectively, and finally adjusted to 950 °C tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com