Vacuum basal plate transmitting system

A transmission system and substrate technology, which is applied in the direction of conveyor objects, electromechanical transmission devices, electromechanical devices, etc., can solve the problems of increased pollution sources of the driving mechanism, vacuum environment pollution, substrate scratches, etc., and achieve fast and effective synchronous transmission of substrates , solve the pollution of the vacuum system, facilitate repair and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

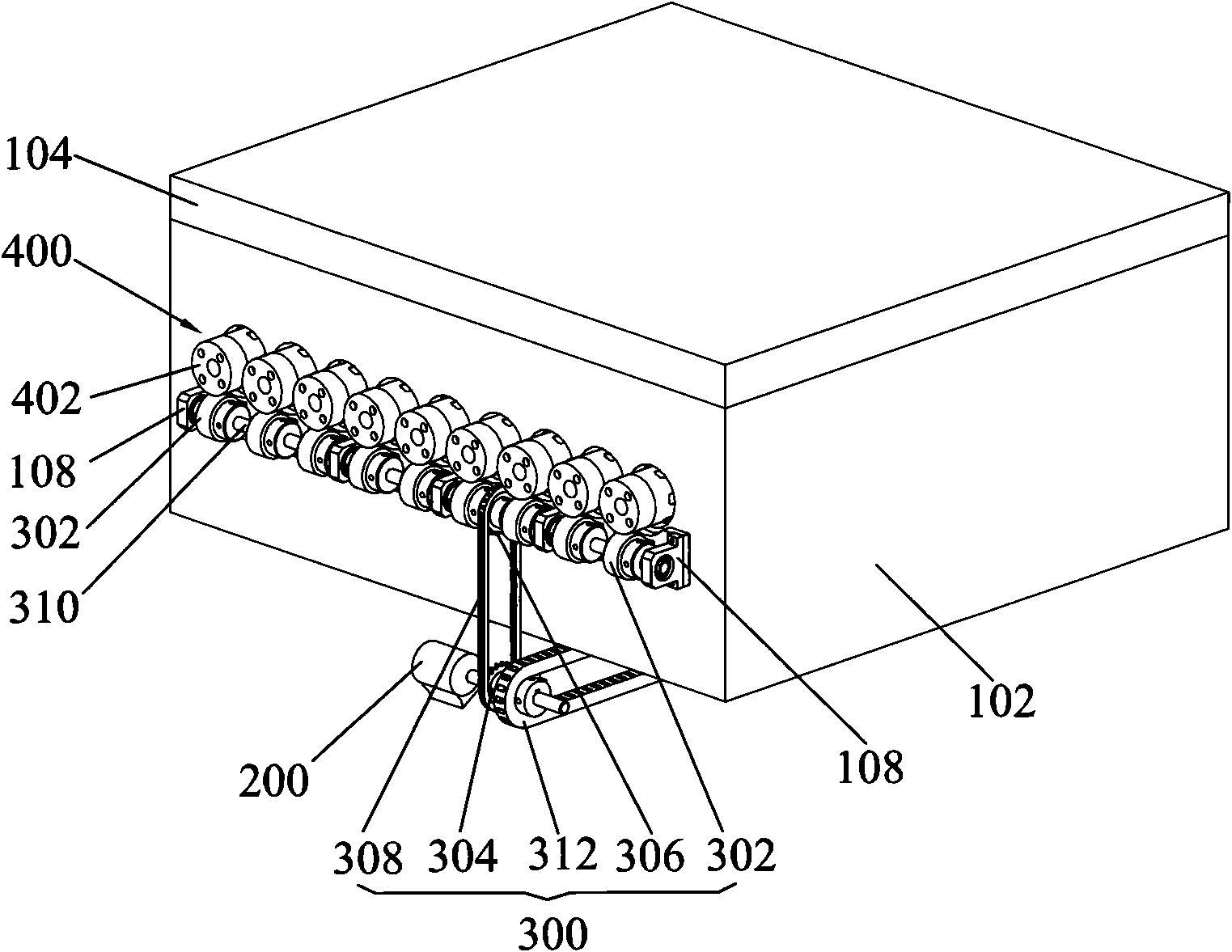

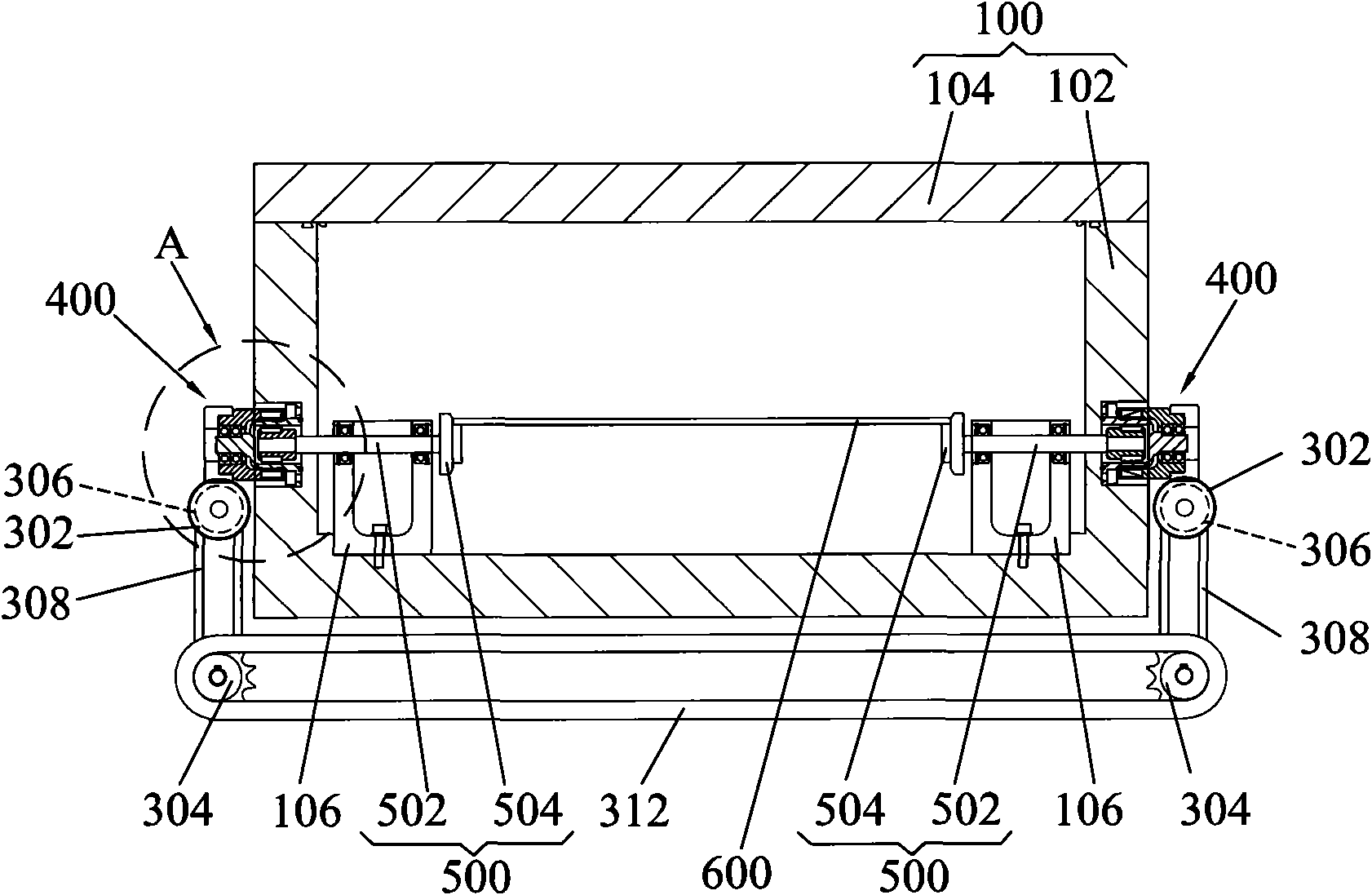

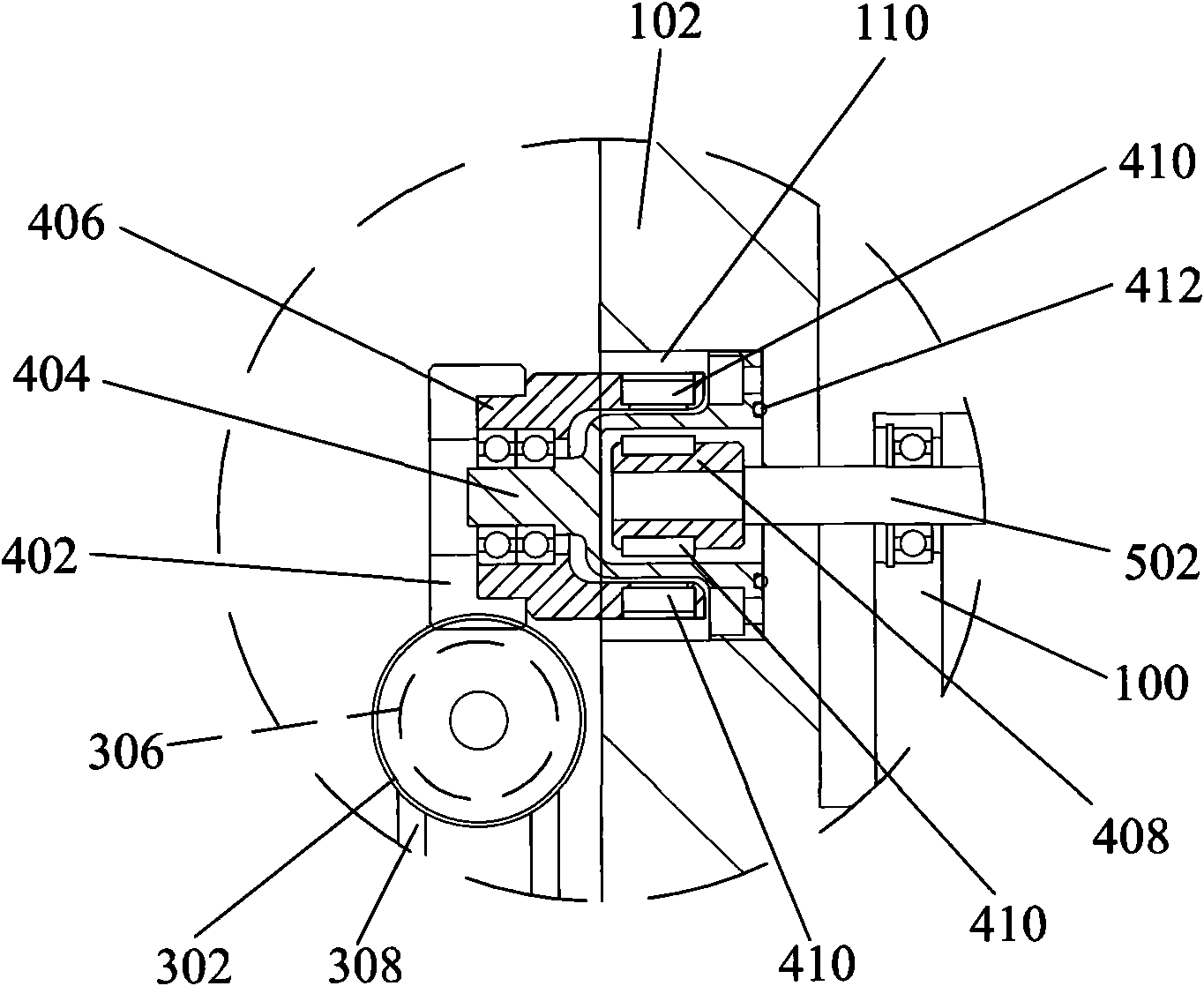

[0016] In order to describe the technical content and structural features of the present invention in detail, the following will be further described in conjunction with the embodiments and accompanying drawings, wherein the same reference numerals in different drawings represent the same components. Such as Figure 1-3 As shown, the present invention discloses a vacuum substrate transfer system, including a closed chamber 100 for forming a vacuum environment, a driving mechanism 200, an outer transmission mechanism 300, a sealed transmission mechanism 400, and an inner transmission mechanism 500, the driving mechanism 200 and the external transmission mechanism 300 are both arranged outside the vacuum chamber 100, the sealed transmission mechanism 400 is arranged on the side wall of the chamber 100, and the power from the external transmission mechanism 300 is transmitted through the sealed transmission mechanism 400 For the internal transmission mechanism 500, the internal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com