Method for extracting apigenin from Chinese violet

A technology of viola ditin and apigenin, which is applied in the direction of organic chemistry, can solve the problems of less development and utilization of active ingredients and low pharmacological activity, and achieve the effects of short separation time, simple separation operation process and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

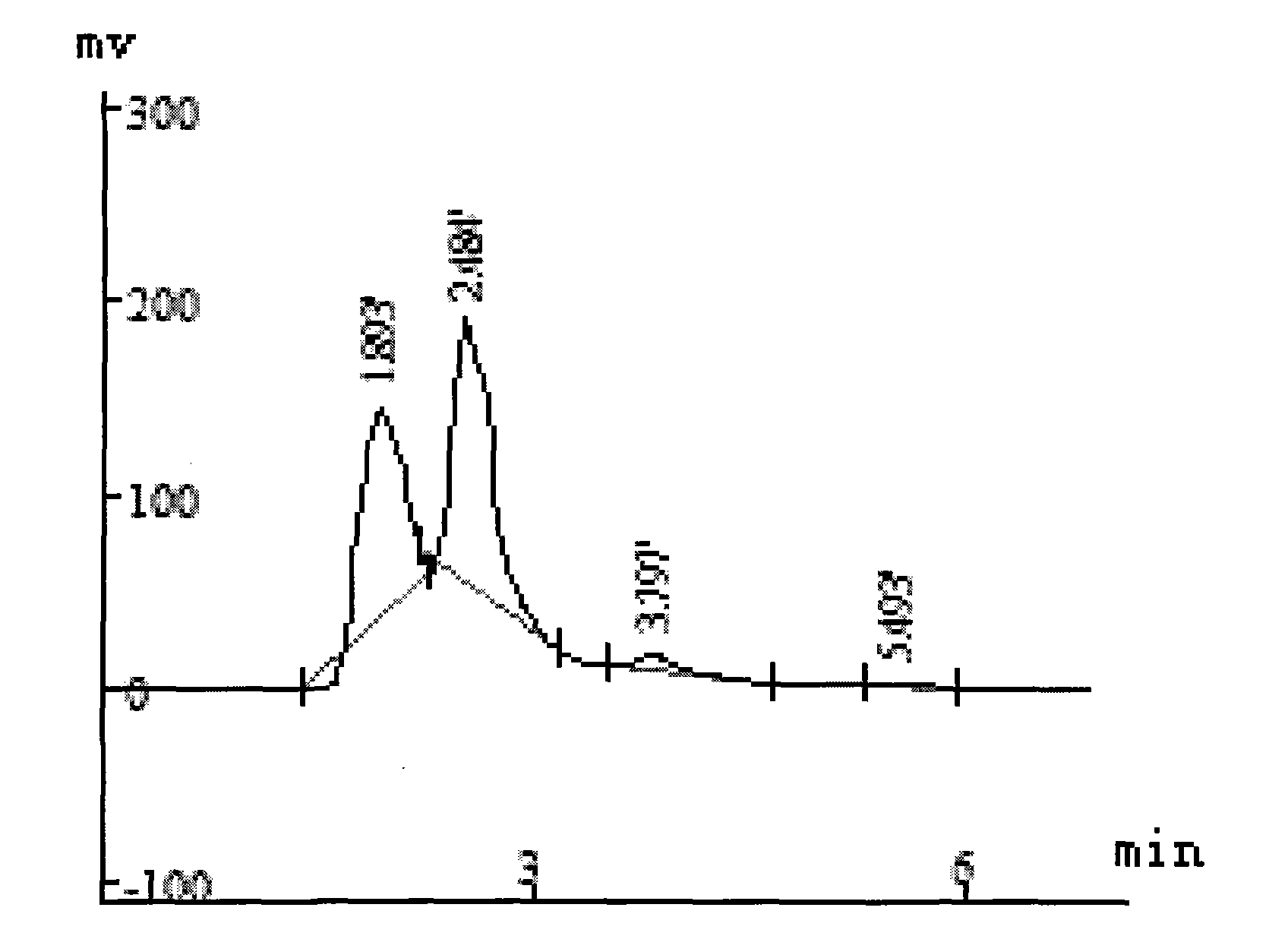

Embodiment 1

[0032] Weigh 500kg of viola powder, add 70% methanol 4000L, ultrasonicate at 50°C for 10min, extract for 30min and then centrifuge for 10min (3000r / min), the precipitate is extracted once with 70% methanol 1000L, and the two supernatants are combined liquid. Concentrate the supernatant to about 100L, add 40L of petroleum ether to the concentrated solution for extraction, remove the lower layer, extract the concentrated solution four times continuously, combine the four lower layer extracts for a total of 160L, and then use ethyl acetate 40L The solution containing petroleum ether was extracted, and after the solution containing petroleum ether was continuously extracted four times, the ethyl acetate part of the upper layer was combined for a total of 160L, and the extract was concentrated to obtain ethyl acetate concentrate, which was stored in a fume hood Dry at 60°C. Completely dissolve ethyl acetate in 10 L of 50% ethanol at 40°C, extract and dry the product, put it on a m...

Embodiment 2

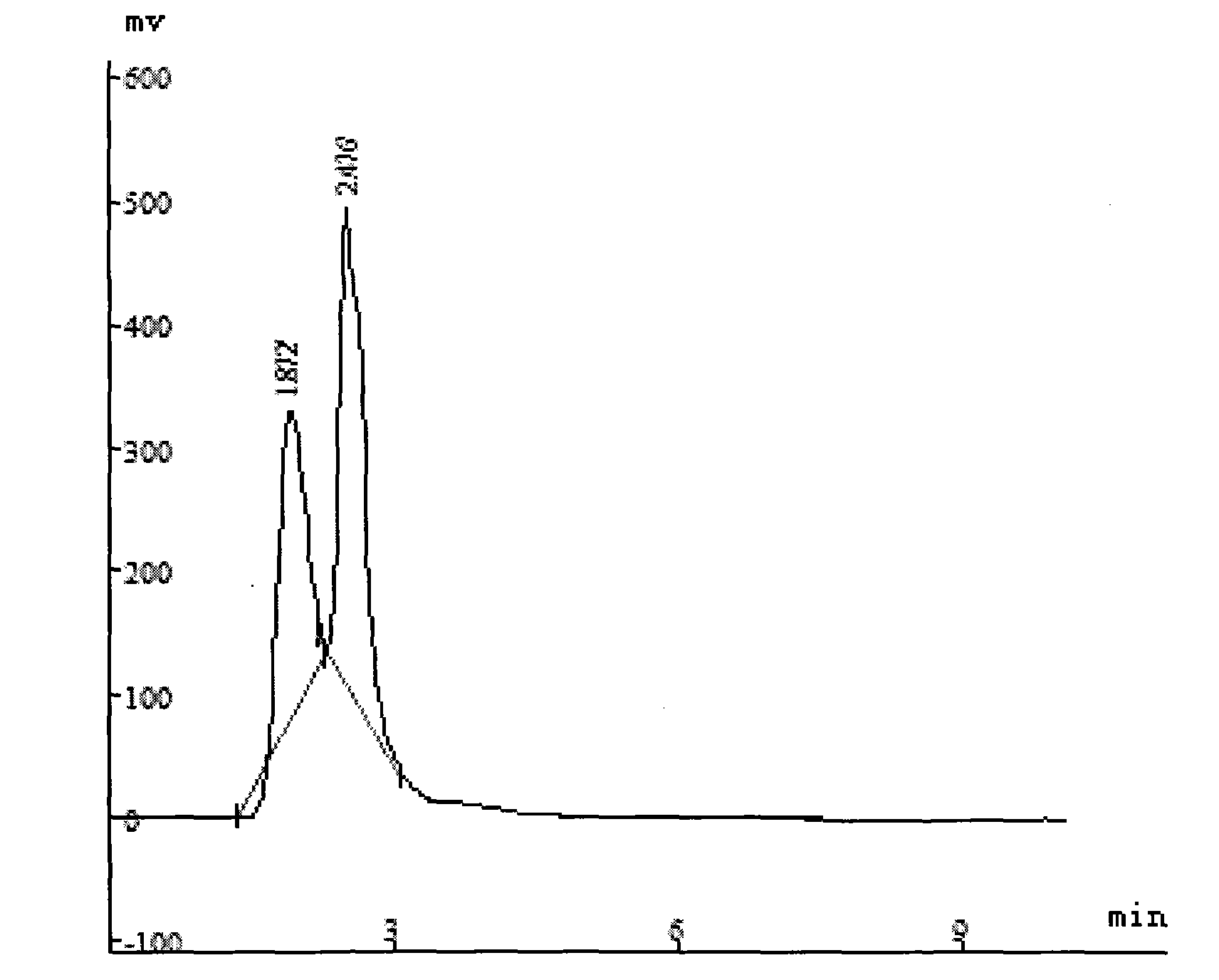

[0038] Weigh 1000kg of viola powder, add 70% methanol 8000L, ultrasonically treat at 50°C for 10min, extract for 30min and then centrifuge for 10min (3000r / min), extract the precipitate once with 70% methanol 2000L, and combine the two supernatants liquid. Concentrate the supernatant to about 200L, add petroleum ether 80L to the concentrated solution for extraction, remove the lower layer, extract the concentrated solution four times continuously, combine the four lower layer extracts for a total of 320L, and then use ethyl acetate 80L The solution containing petroleum ether was extracted, and after the solution containing petroleum ether was continuously extracted four times, the ethyl acetate part of the upper layer was combined for a total of 320L, and the extract was concentrated to obtain ethyl acetate concentrate, which was stored in a fume hood Dry at 60°C. Completely dissolve ethyl acetate in 20 L of 50% ethanol at 40°C, extract and dry the product, put it on a macrop...

Embodiment 3

[0040] Weigh 300kg of viola powder, add 2000L of 70% ethanol, ultrasonicate for 10min at 50°C, extract for 30min and then centrifuge for 10min (3000r / min), extract the precipitate once with 1000L of 70% ethanol, and combine the two supernatants liquid. Concentrate the supernatant to about 50L, add petroleum ether 30L to the concentrated solution for extraction, remove the lower layer, extract the concentrated solution four times continuously, combine the four lower layer extracts for a total of 120L, and then use ethyl acetate 30L The solution containing petroleum ether is extracted, and after the solution containing petroleum ether is continuously extracted four times, the ethyl acetate part of the upper layer is combined for a total of 120L, and the extract is concentrated to obtain ethyl acetate concentrate. Dry at 60°C. Completely dissolve ethyl acetate in 10 L of 50% ethanol at 40°C, extract and dry the product, put it on a macroporous adsorption resin LSA-10 column, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com