Method for separating and purifying 5'-cytidylic acid and derivatives thereof

A technology for separation, purification and derivatives, which is applied to the preparation of sugar derivatives, sugar derivatives, and sugar derivatives, etc., can solve the problems of large equipment scale, long production cycle, long operation process, etc., and achieves high selectivity and simple steps. , does not destroy the effect of biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

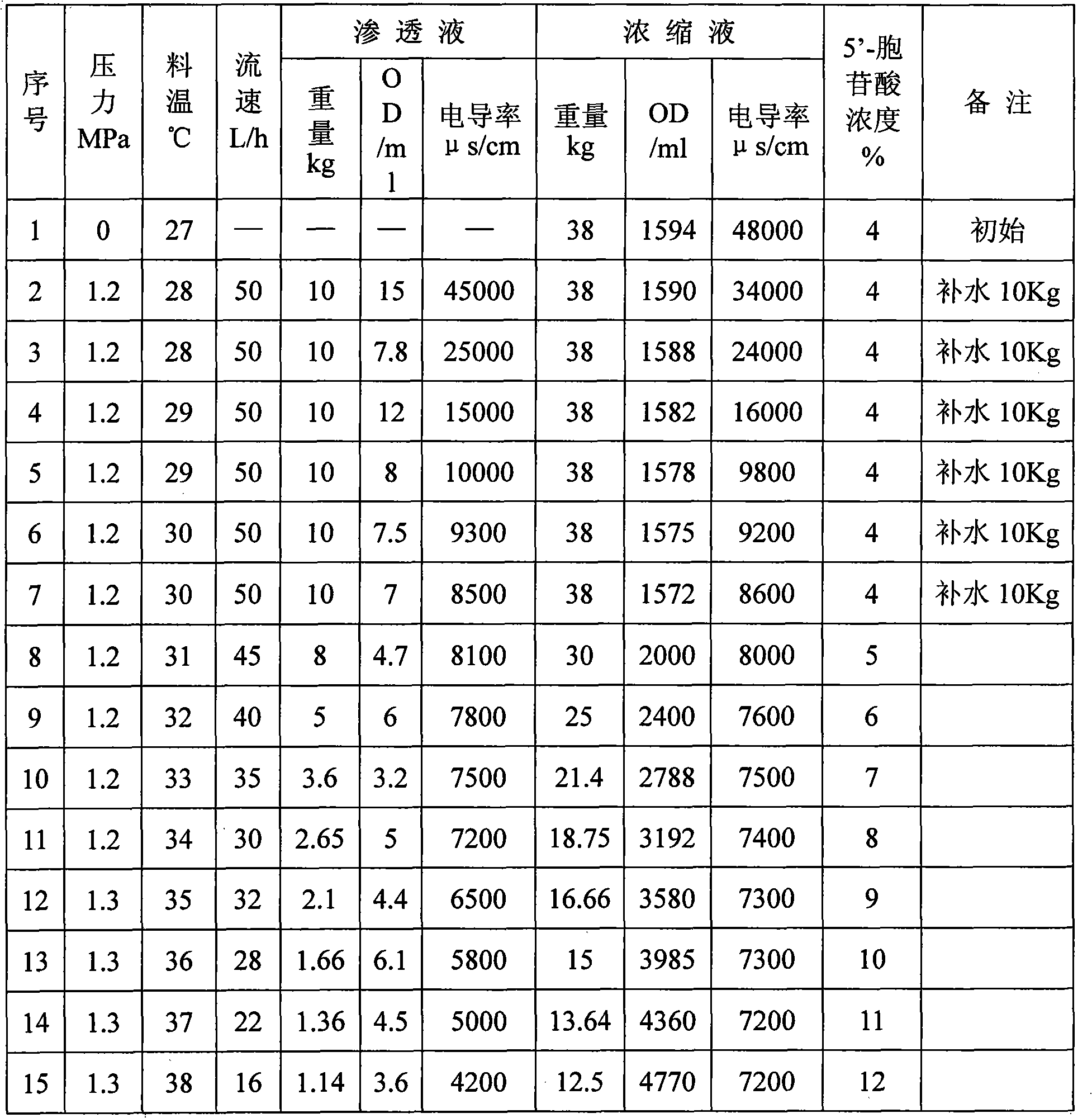

Embodiment 1

[0046] Step 1, prepare the solution to be separated;

[0047] Take 1.5kg of 5'-cytidylic acid, 1.5kg of sodium chloride, 1kg of sodium dihydrogen phosphate, add 35kg of distilled water, adjust the pH value to 5.0±0.1 with 30% sodium hydroxide solution, and then add distilled water to a total weight of 38kg;

[0048] Step 2, pour the solution to be separated into the feed liquid tank;

[0049] Step 3, carry out desalination operation;

[0050] Step 3.1, operate the equipment, and adjust the pressure to 1.2-1.5 MPa by the pressure regulating device, so that the solution to be separated passes through the nanofiltration membrane;

[0051] Step 3.2, collect the permeate, and return the retained liquid to the feed liquid tank;

[0052] Step 3.3, control the material concentration and keep the liquid level of the material in the feed liquid dregs, that is, add 10 kg of distilled water when the feed liquid in the feed liquid dregs reduces the weight by 10 kg (i.e. the permeate is c...

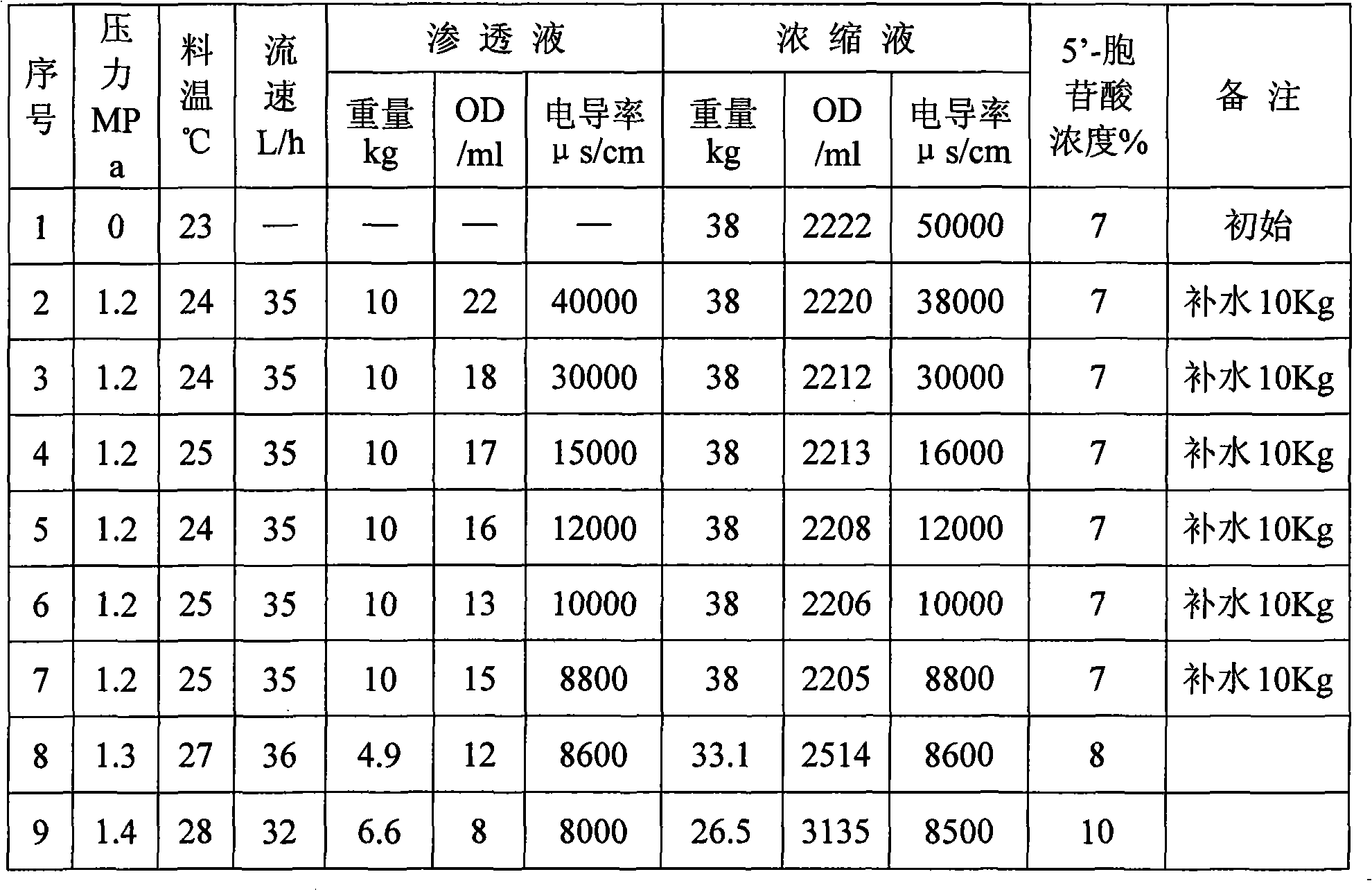

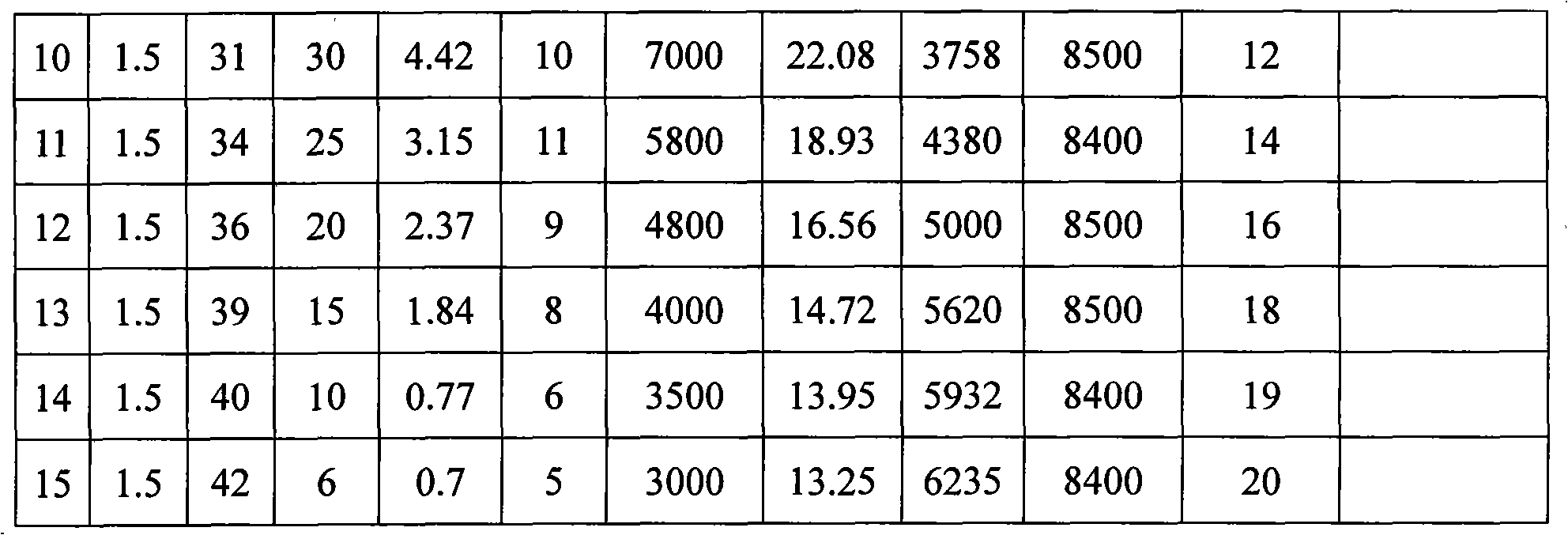

Embodiment 2

[0064] Step 1, prepare the solution to be separated;

[0065] Take 15Kg of the water phase extracted and stratified in the crude synthesis production of 5'-cytidylic acid workshop, add 22Kg of distilled water to dilute, adjust the pH value to 5.0±0.1 with 30% sodium hydroxide solution, and the solution contains about 5' - 2.65kg of cytidylic acid, the inorganic salts are mainly sodium chloride and sodium dihydrogen phosphate;

[0066] Step 2, pour the solution to be separated into the feed liquid tank;

[0067] Step 3, carry out desalination operation;

[0068] Step 3.1, operate the equipment, and adjust the pressure to 1.2-1.5 MPa by the pressure regulating device, so that the solution to be separated passes through the nanofiltration membrane;

[0069] Step 3.2, collect the permeate, and return the retained liquid to the feed liquid tank;

[0070] Step 3.3, control the material concentration and keep the liquid level of the material in the feed liquid dregs, that is, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com