Thermal regenerant for asphalt concrete pavement and preparation method thereof

A technology of asphalt concrete and thermal regeneration agent, which is applied in the directions of reagents, building components, building insulation materials, etc., can solve the problems of weak interface between layers and longitudinal cold joints, difficult to mass-produce, and difficult to meet the requirements of compaction, etc. Achieve the effect of eliminating weak joints and weak interfaces, improving the quality of pavement repairs, and being easy to mass-produce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

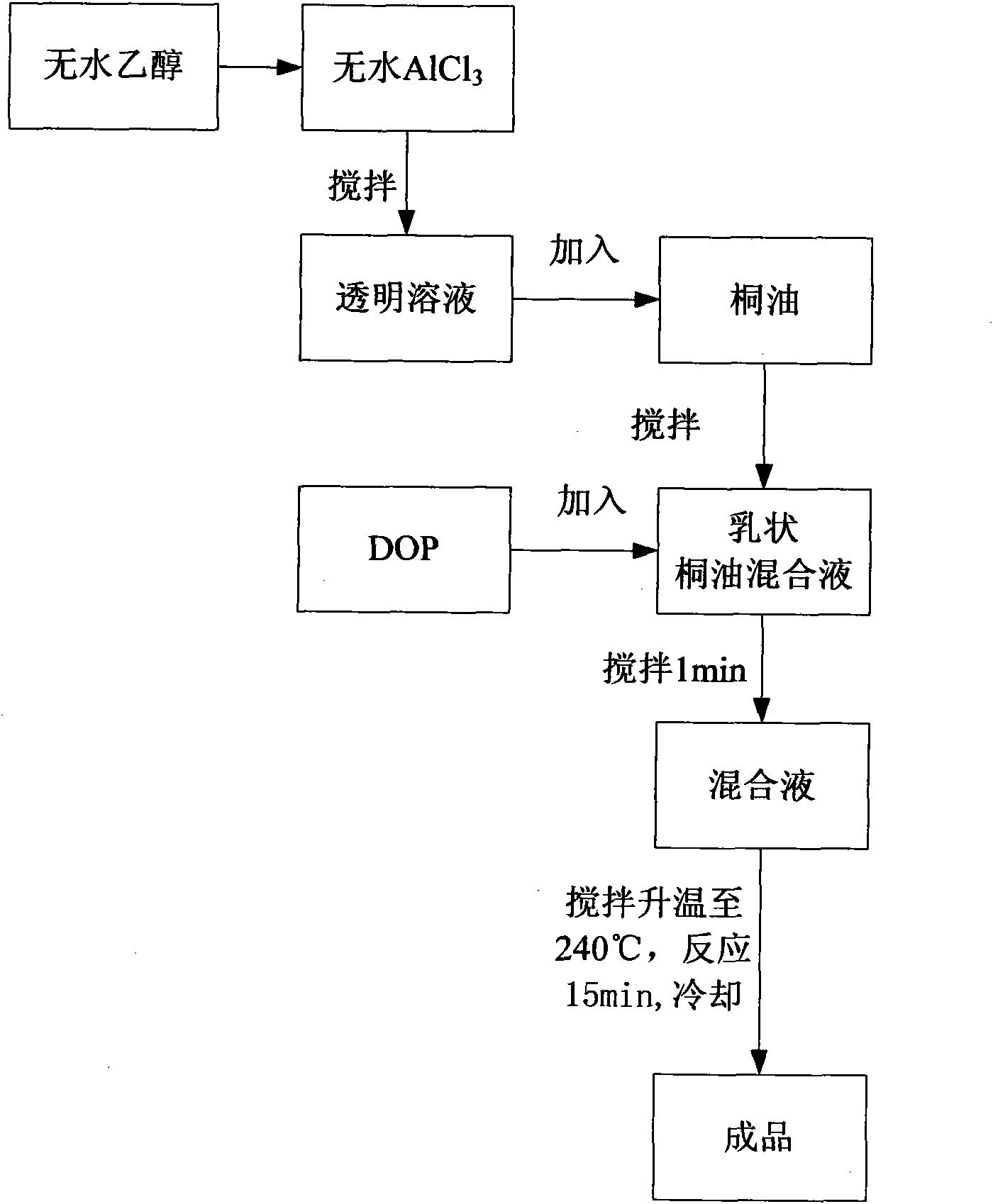

Method used

Image

Examples

Embodiment Construction

[0036] The performance index of tung oil selected by the present invention, DOP is shown in Table 2, Table 3 respectively

[0037] Table 2 Properties of Tung Oil

[0038] Indicator name

Index value

color

light yellow

Specific gravity(25℃)

0.94

typical value

1.66

6

Light component content (%)

15

Aroma content (%)

75

[0039] Table 3 Properties of dimethyl phthalate

[0040] Indicator name

Index value

color

colorless, transparent liquid

Specific gravity(25℃)

1.05

Flash point (°C)

175

Dissolving temperature (°C)

-40

[0041] In order to determine the input amount of each component, according to the properties of the regenerant components and the performance requirements of the regenerant, the main factors are the amount of tung oil (A), the amount of anhydrous aluminum trichloride (B), and the amount of ...

PUM

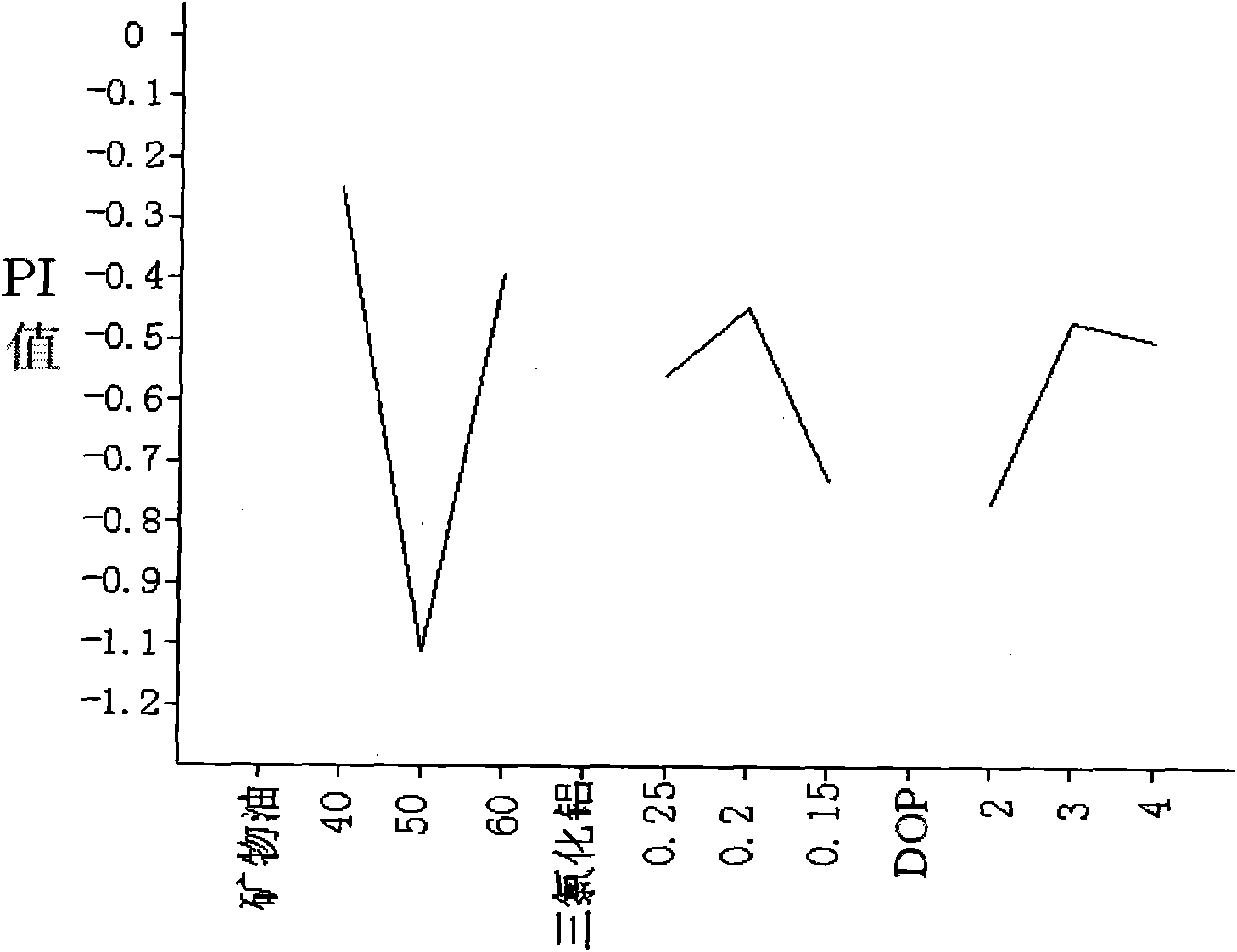

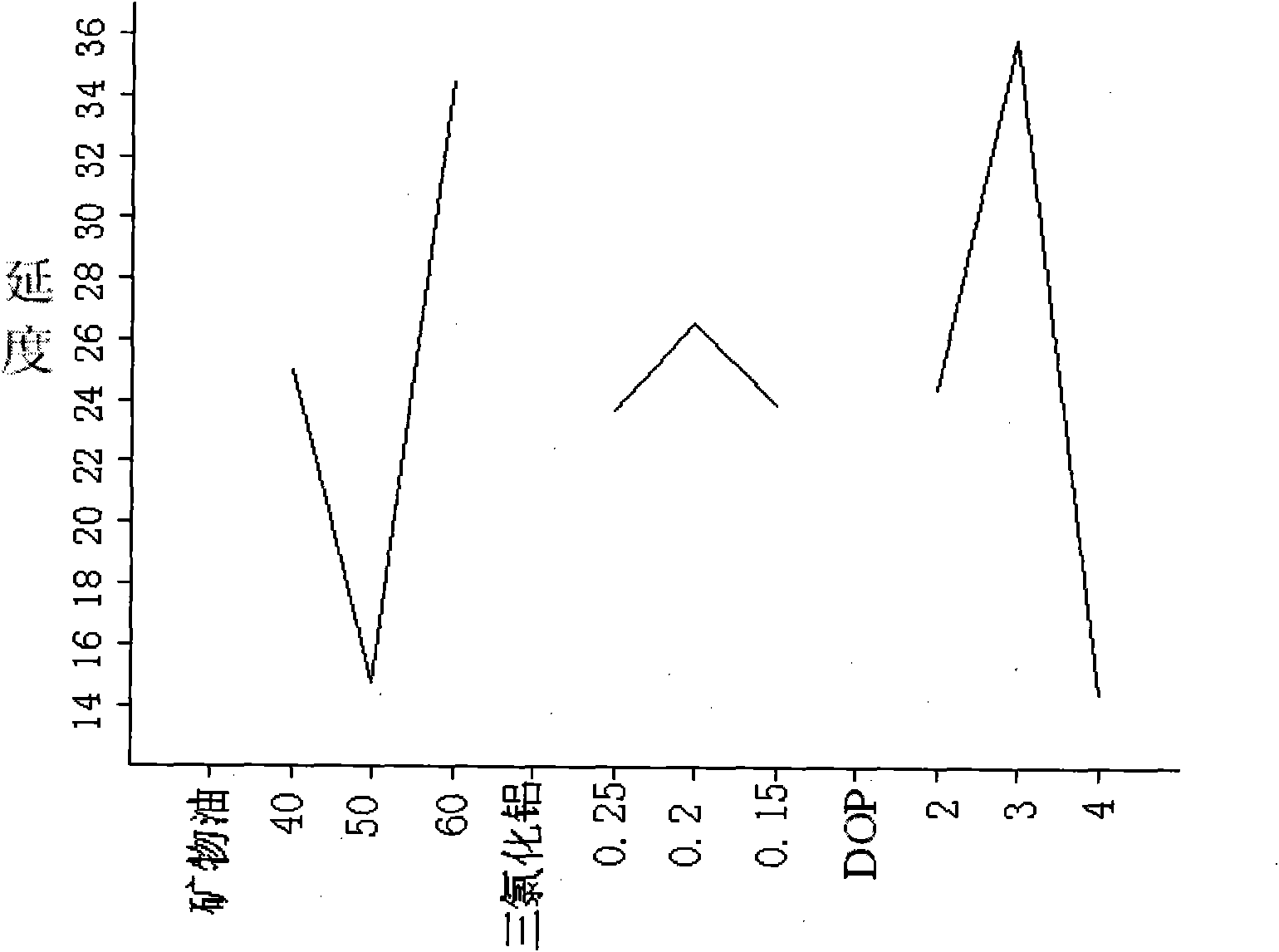

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com