Method for preparing aqueous-phase semiconductor nanocrystalline by using ammonia compound for catalysis

A technology for catalytic preparation and semiconductor, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve the problems of limiting the scale and practical use of semiconductor nanocrystals, energy consumption, and long reaction time of nanocrystals, so as to shorten the Preparation cycle and energy consumption, effect of high fluorescence quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1: with Te powder and NaBH 4 Preparation of NaHTe aqueous solution as raw material

[0031] Via Te powder and NaBH 4Reaction to prepare NaHTe aqueous solution: first 0.34g NaBH 4 Fully dissolve in 6mL deionized water, then add 0.51g Te powder, leaving only one pinhole in the reaction system to discharge the hydrogen generated in the system, and react in an ice-water bath for 8 hours to obtain a 0.666mol / L NaHTe aqueous solution.

[0032] 2: with CdCl 2 , NaHTe, and mercaptopropionic acid as raw materials to synthesize CdTe nanocrystal precursor solution

[0033] Add 4×10 to the 20ml reaction system -4 mol of CdCl 2 and 9.6×10 -4 mol of mercaptopropionic acid, adjust the pH to 9.3 with NaOH, and pass N 2 Gas protection; add 0.12mL, 0.666mol / L NaHTe aqueous solution under stirring condition; CdCl 2 , NaHTe, and mercaptopropionic acid in a molar ratio of 1:0.2:2.4, and continued stirring for 10 minutes to obtain a CdTe nanocrystal precursor solution.

[0034] 3: R...

Embodiment 2

[0037] 1: Synthetic NaHTe method is as described in Example 1;

[0038] 2: The method for synthesizing the CdTe nanocrystal precursor solution is as described in Example 1;

[0039] 3: Rapid growth of precursor solution

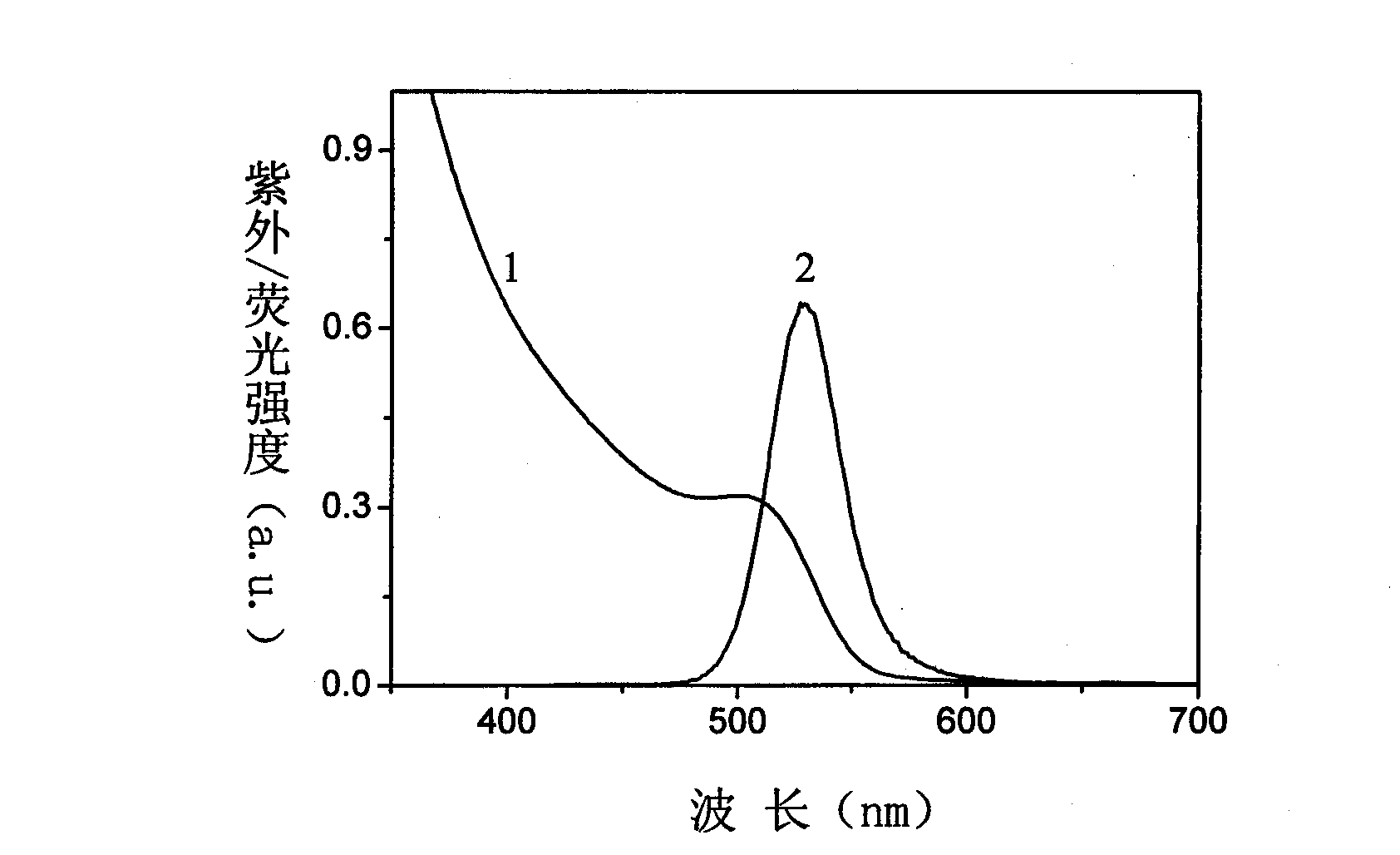

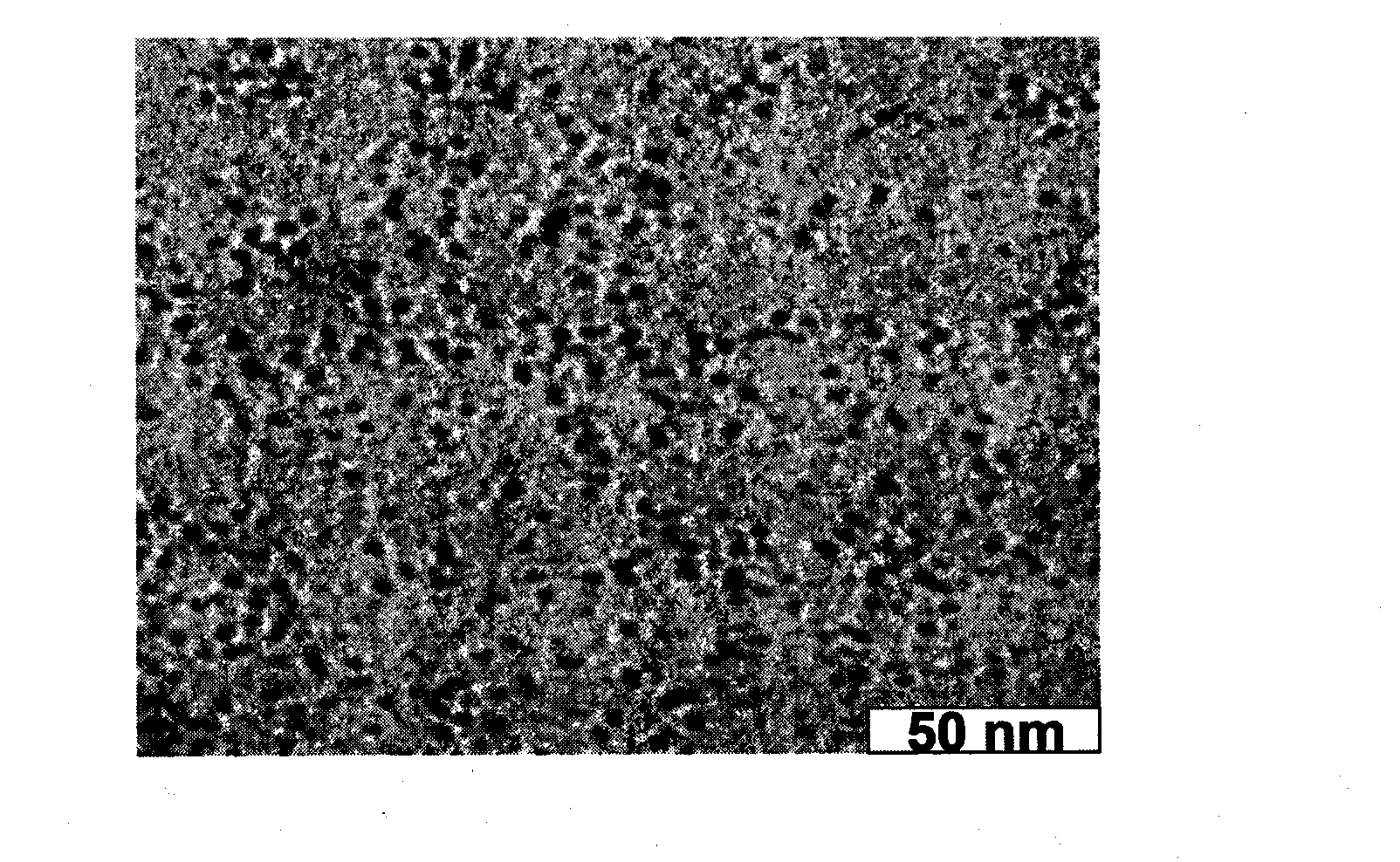

[0040] Add 1 mL of freshly prepared CdTe precursor solution and 85 wt% N to the 40 mL reaction system 2 h 4 ·H 2 O solution 27.36mL, where Cd 2+ with N 2 h 4 ·H 2 The molar ratio of O is 1:24000. After the solution was placed in the dark at room temperature for 2 hours, if Figure 2(a) , 2(b) As shown, the obtained fluorescent color is yellow (the emission peak is 565nm), and the average particle size is 3.06nm CdTe nanocrystals.

Embodiment 3

[0042] 1: Synthetic NaHTe method is as described in Example 1

[0043] 2: Synthesis of CdTe nanocrystal precursor solution method as described in Example 1

[0044] 3: Rapid growth of precursor solution

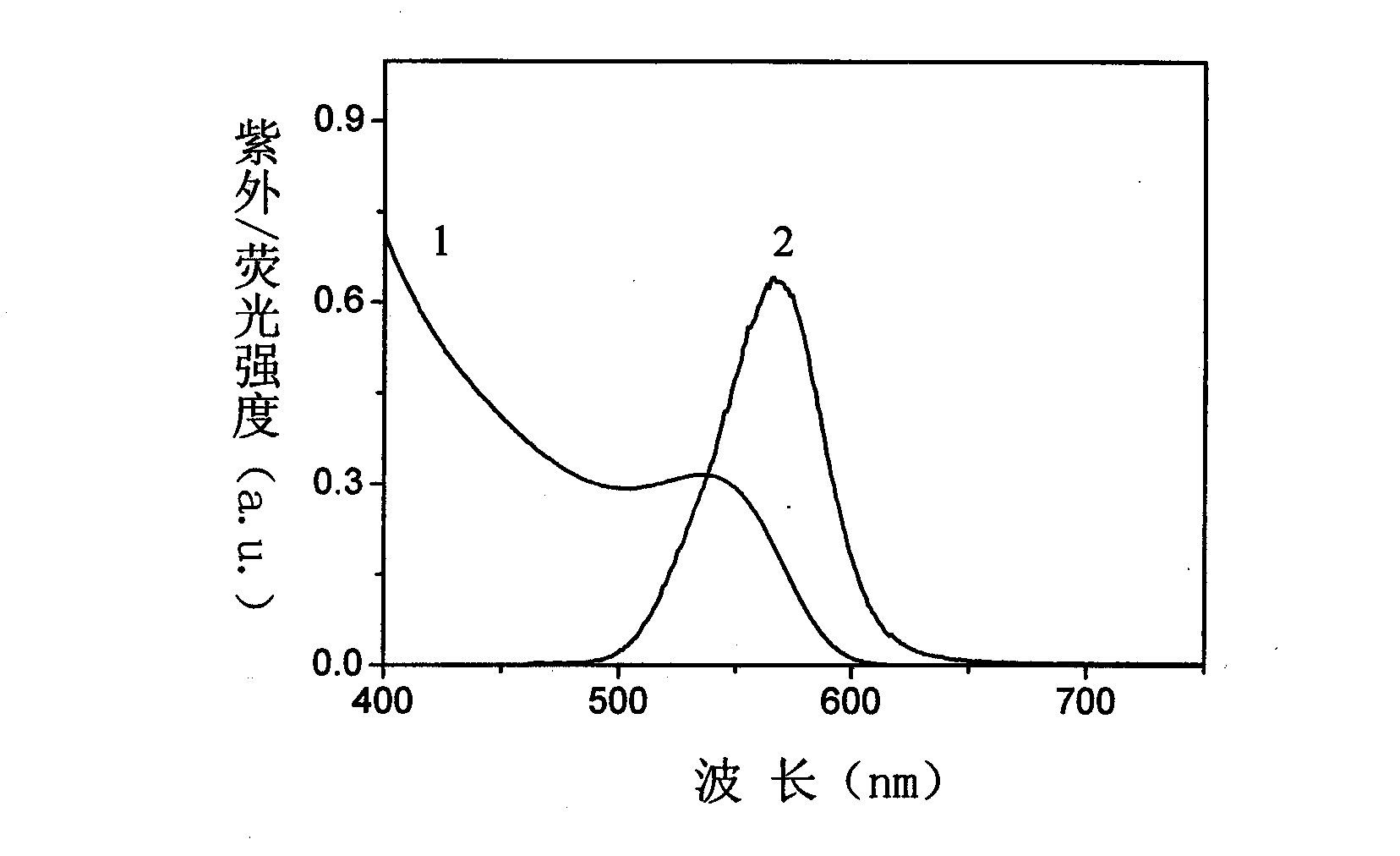

[0045] Add 1 mL of freshly prepared CdTe precursor solution and 85 wt% N to the 40 mL reaction system 2 h 4 ·H 2 O solution 27.36mL, where Cd 2+ with N 2 h 4 ·H 2 The molar ratio of O is 1:24000. After the solution was kept in the dark at room temperature for 24 hours, if Figure 3(a) , 3(b) As shown, the obtained fluorescent color is orange (emission peak is 597nm), and the average particle size is 3.37nm CdTe nanocrystal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com