Absolute spectral radiance luminance responsivity calibrating system utilizing wide tunable laser

A technology of spectral radiance and responsivity, which is applied in the field of remote sensing science and optical radiation measurement, can solve the problems of difficulty in improving the accuracy and cannot meet the needs of quantitative remote sensing, and achieves the effect of simple structure and improved calibration accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

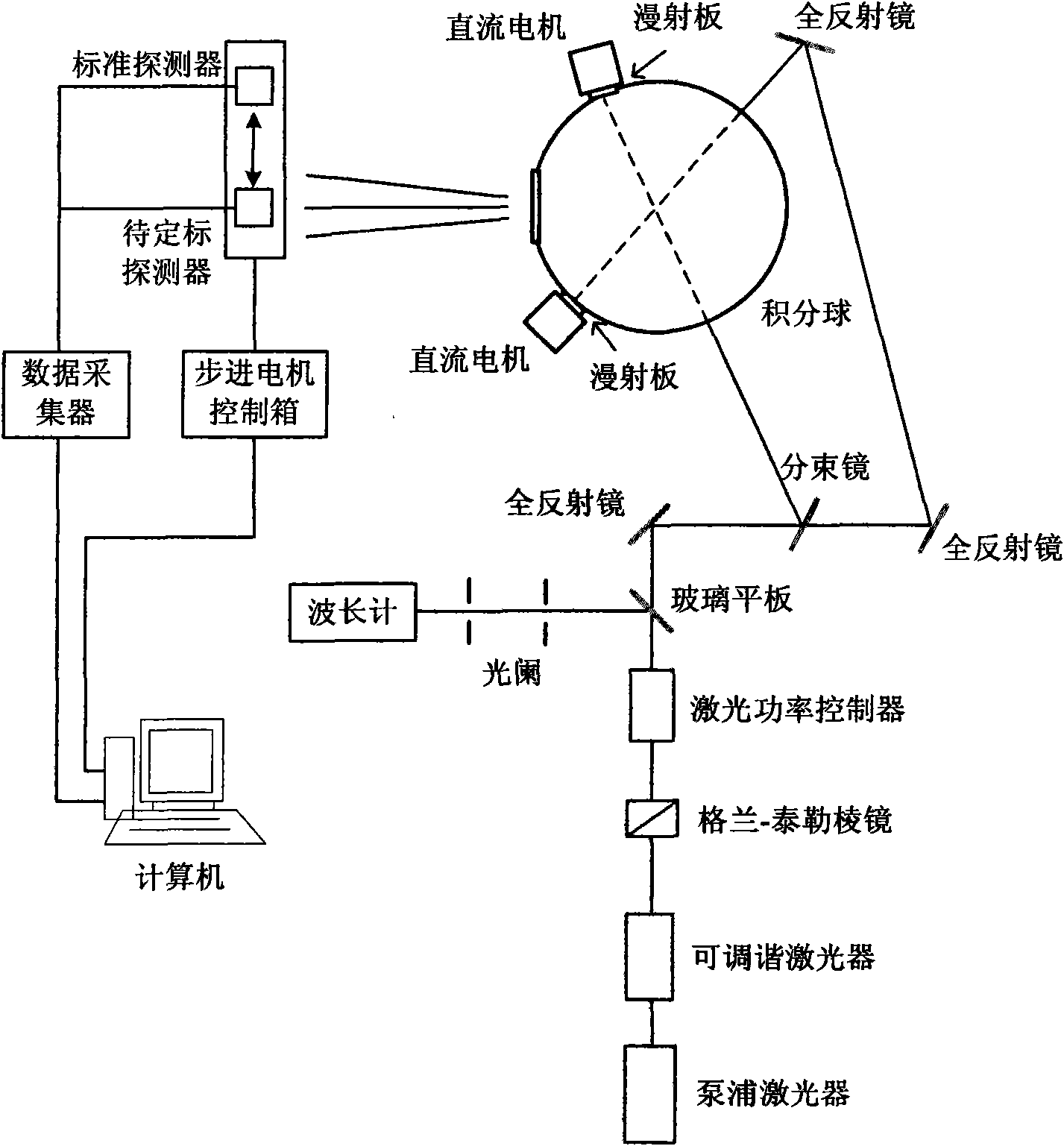

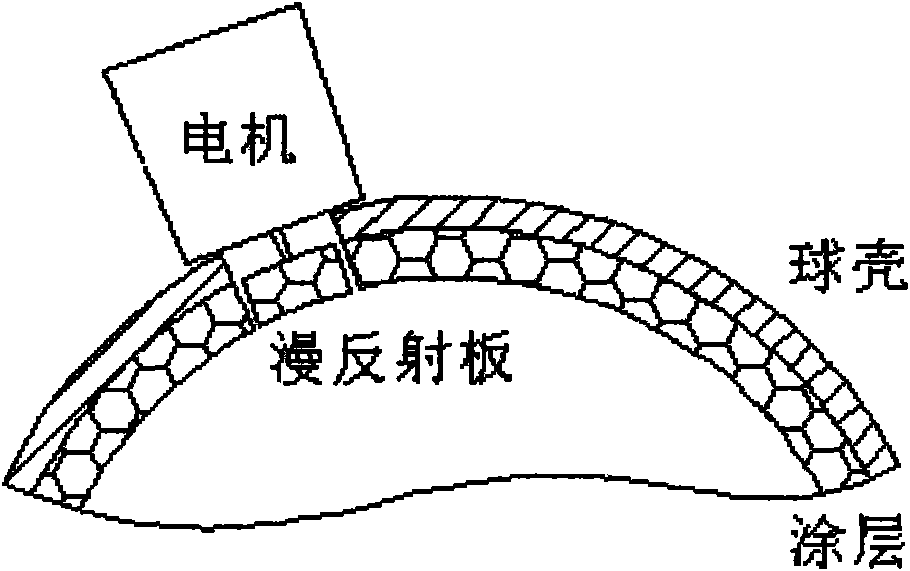

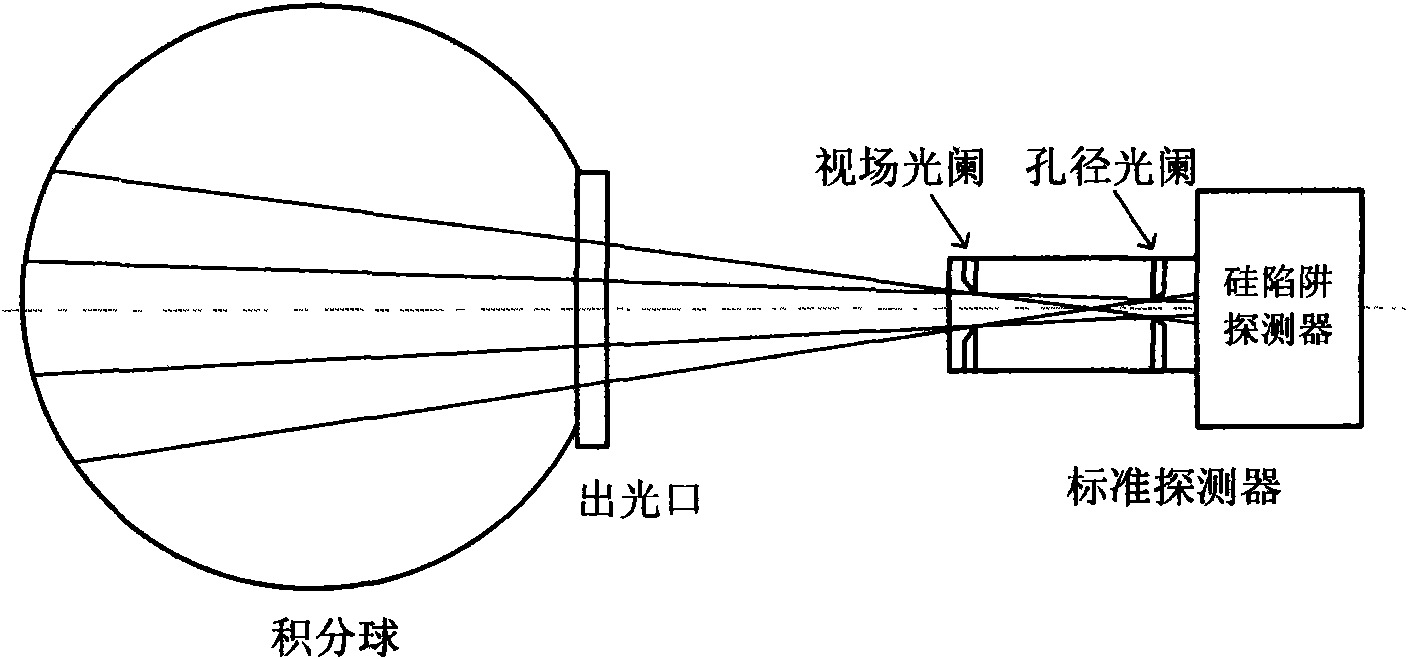

[0018] The absolute spectral radiance responsivity calibration system using a wide tunable laser includes a two-dimensional mobile platform, the movement of the two-dimensional mobile platform is controlled by a computer through a stepping motor control box, and a standard detector is placed on the two-dimensional mobile platform. The detector and the detector to be calibrated also include a calibration light source, the outgoing light of the calibration light source can be irradiated into the standard detector and the detector to be calibrated on the two-dimensional mobile platform, and the calibration light source includes an integrating sphere and a tunable laser In the system, the output light of the tunable laser is guided into the integrating sphere, and exits at the light outlet of the integrating sphere to form a calibration light source. The standard detector and the detector to be calibrated successively observe the center of the light outlet of the integrating sphere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com