Corrosion inhibitor suitable for complex wastewater of oilfield and preparation method thereof

A corrosion inhibitor and complex technology, applied in the field of corrosion inhibitor and its manufacturing, can solve the problems of lack of corrosion inhibitor and poor corrosion inhibition effect of sewage, etc., and achieve the effect of high salinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

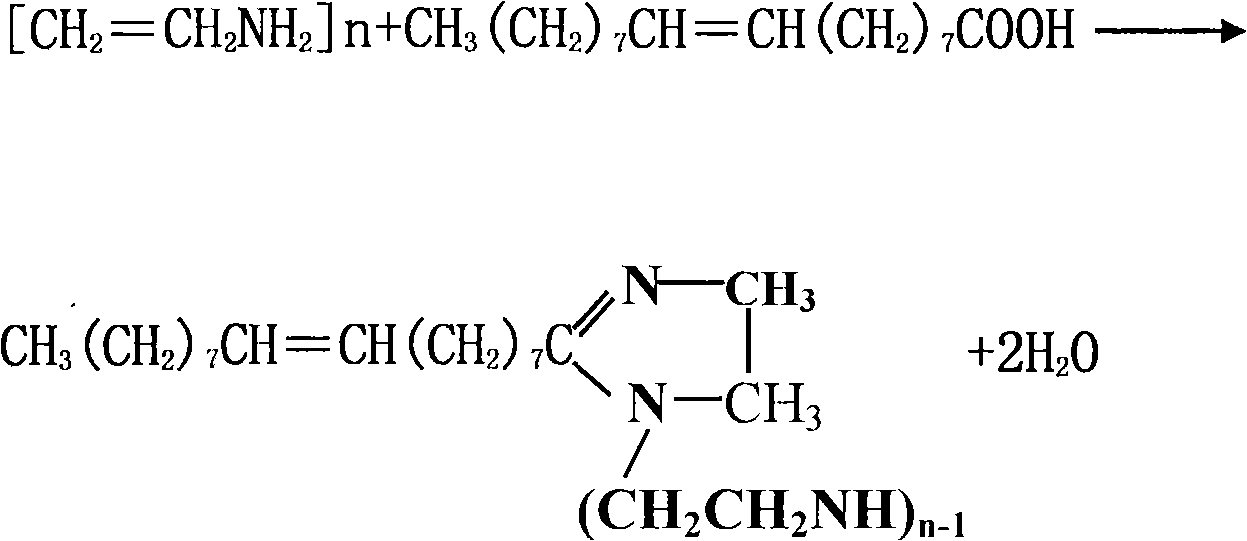

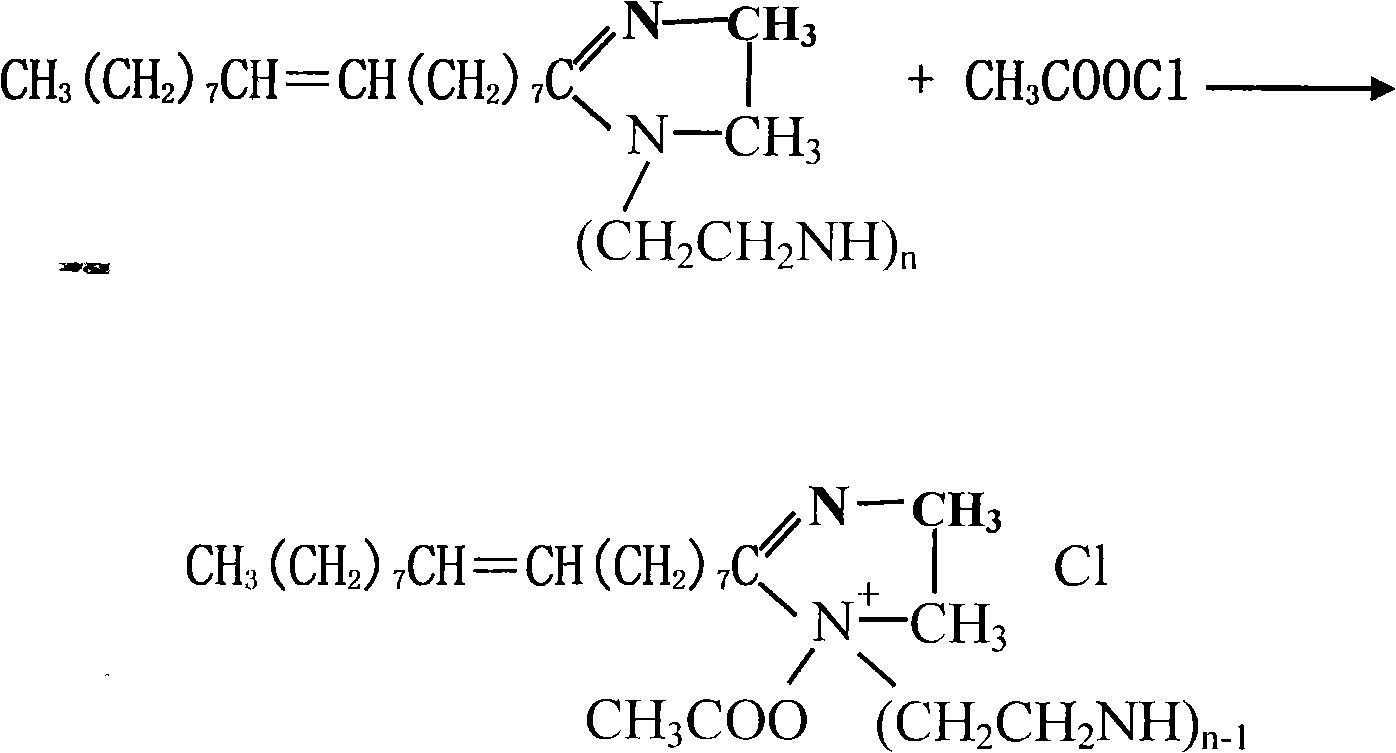

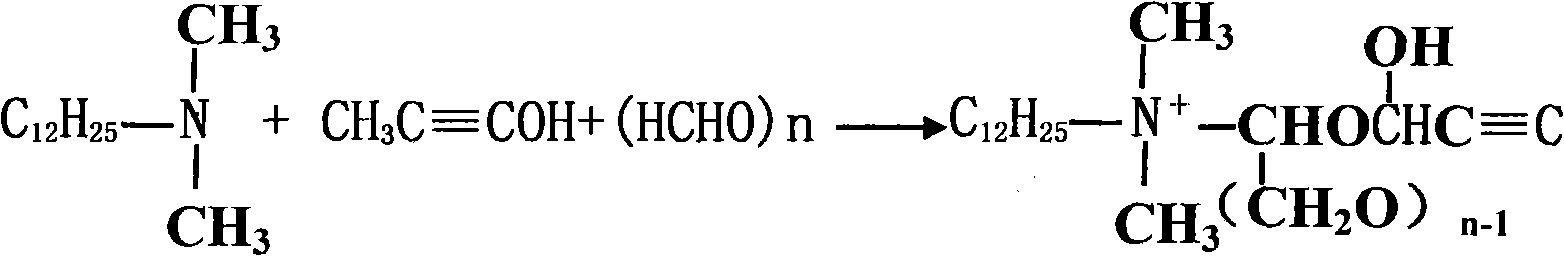

[0050] Embodiment 1, according to the first step and the second step of the manufacturing method of corrosion inhibitor of the present invention mentioned above, imidazoline chloroacetate corrosion inhibitor and alkynyloxymethylamine quaternary ammonium salt corrosion inhibitor were prepared respectively;

[0051] Synthesis of the first step imidazoline chloroacetate corrosion inhibitor

[0052] A. Synthesis of oxazoline matrix

[0053] raw material:

[0054] Polyethylene polyamine, molecular formula [CH 2 =CH 2 NH 2 ]n (property: yellow or orange-red transparent viscous liquid, co-product of ethylenediamine, diethylenetriamine, triethylenetetramine and tetraethylenepentamine)

[0055] Oleic acid (cis-9-+ octa(carbon)enoic acid), molecular formula CH 3 (CH 2 ) 7 CH=CH(CH 2 ) 7 COOH;

[0056] By mass ratio of polyethylene polyamine and oleic acid:

[0057] [CH 2 =CH 2 NH2 ]n:CH 3 (CH 2 ) 7 CH=CH(CH 2 ) 7 COOH=1.1,

[0058] Add it into the reaction kettle, rai...

Embodiment 2

[0072] Embodiment two, also according to the first step and the second step of the manufacture method of the above-mentioned corrosion inhibitor of the present invention, but during the synthesis of the oxazoline substrate in the synthetic A process of the imidazoline chloroacetate corrosion inhibitor in the first step By mass ratio of polyethylene polyamine and oleic acid:

[0073] [CH 2 =CH 2 NH 2 ]n:CH 3 (CH 2 ) 7 CH=CH(CH 2 ) 7 COOH=1.2, other conditions are unchanged, respectively make imidazoline chloroacetate corrosion inhibitor and alkynoxymethylamine quaternary ammonium salt corrosion inhibitor;

[0074] The third step is to compound the corrosion inhibitor-II according to the mass ratio of imidazoline chloroacetate corrosion inhibitor: alkynyloxymethylamine quaternary ammonium salt corrosion inhibitor = 1:2.

Embodiment 3

[0075] Embodiment three, also according to the first step and the second step of the manufacturing method of corrosion inhibitor of the present invention mentioned above, respectively make imidazoline chloroacetate corrosion inhibitor and alkynoxymethylamine quaternary ammonium salt corrosion inhibitor;

[0076] The third step is to compound the corrosion inhibitor-III according to the mass ratio of imidazoline chloroacetate corrosion inhibitor: alkynyloxymethylamine quaternary ammonium salt corrosion inhibitor = 2:1.

[0077] Application of corrosion inhibitor of the present invention in Dagang area. For example, Zaoda Station in Dagang Oilfield: the temperature at this station is 65°C, the salinity is 50,000mg / L, the hydrogen sulfide content is 30mg / L, the blank corrosion rate of the on-site coupon is 1.5mm / a, and the test piece is partially corroded and pitted After adding 30mg / L of corrosion inhibitor-I of the present invention, the corrosion rate is 0.015mm / a, the corrosi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com