Production method of rice wine

A production method and rice wine technology, applied in the production field of rice wine, can solve the problems of poor taste, poor saccharification and fermentation, thin wine taste, etc., and achieve the effects of reducing production costs, enriching varieties, and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

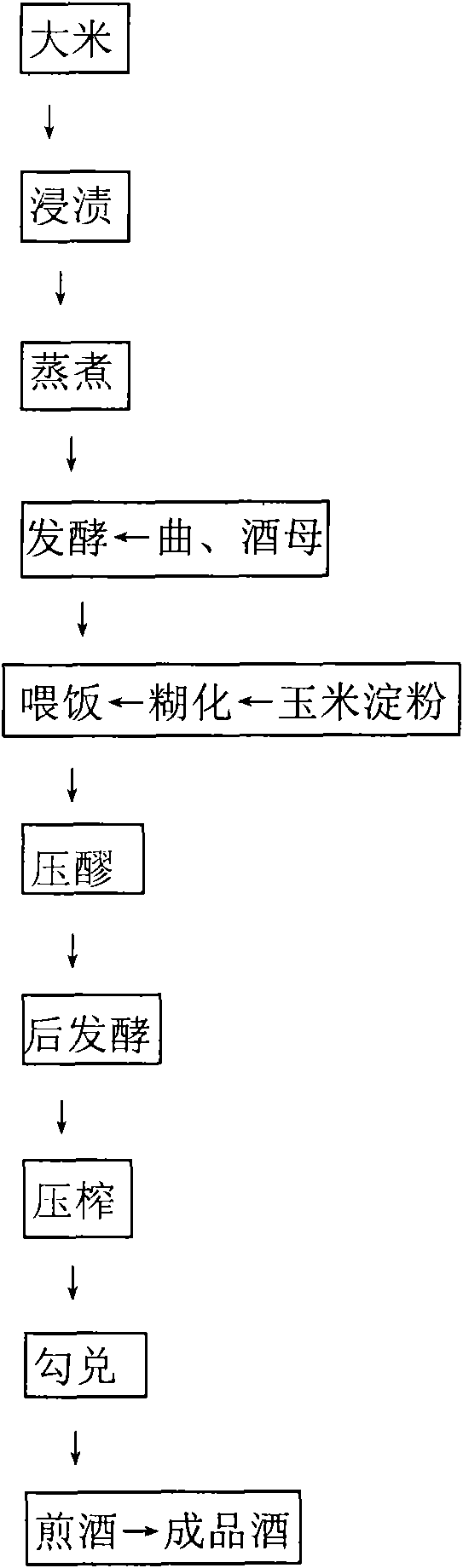

[0010] Example 1, according to Figure one The given production process flow diagram. The specific technological process of the present invention is that 8568 kilograms of japonica rice, 2,000 kilograms of japonica rice, 800 kilograms of raw koji, 4 kilograms of glucoamylase, 8 kilograms of amylase, and 10 kilograms of protease are fed at 8 o'clock in the morning that day. 9.6 tons of corn flour after liquefaction was put at 10 am the next day.

[0011] The steps of corn liquefaction are as follows: 2 tons of corn flour are divided equally into five portions, each portion is heated to 40°C with 1.52 tons of water, 250g compound enzyme and 500g calcium chloride are added to each portion-1.5°C / min. Heat to 70-72°C-keep warm 40 minutes -1.0°C / min, heating up to 95°C-keeping warm for 15 minutes-iodine reaction-1°C / min, cooling down to 30°C-putting in the front fermentation tank

[0012]

1 day

2 days

4 days

5 days

11 days after leavening

15 days

22 days

26 days

Alcoh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com