TiNiNb/NbTi memory alloy composite material and preparation method thereof

A composite material and memory alloy technology, which is applied to the composite material of TiNiNb memory alloy and its preparation, and the field of TiNiNb/NbTi memory alloy composite material and its preparation, can solve the problems of limited application of damping materials, low yield strength, etc., to meet the demand , good plasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of TiNiNb / NbTi memory alloy composite material provided by the invention can comprise the following specific steps:

[0040] (1) selecting niobium with a purity of 99.9wt.%, titanium with a purity of 99.9wt.%, and nickel with a purity of 99.9wt.% according to the composition ratio of the composite material;

[0041] (2) Putting the above-mentioned composite material components into a smelting furnace, smelting to obtain a TiNiNb / NbTi memory alloy composite material, and casting it into an ingot;

[0042] (3) In a vacuum furnace, perform homogenization annealing on the cast ingot at 950°C for 10 hours;

[0043] (4) Hot forging the annealed ingot at 850°C radially into a cake-shaped material;

[0044] (5) Plastic processing is repeated on the cake-shaped material obtained by hot forging until the required profile is obtained.

Embodiment 1

[0045] Embodiment 1: Preparation of Nb 60 Ti 25 Ni 15 memory alloy composite

[0046] (1) by Nb content 60at.%, the ratio of Ti and Ni atomic ratio 5: 3 selects the niobium that purity is 99.9wt.%, the titanium that purity is 99.9wt.%, the nickel that purity is 99.9wt.%, wherein , the sum of the atomic percentages of Nb, Ti and Ni is 100%;

[0047] (2) Put the above-mentioned alloy components into a smelting furnace, melt and cast them into ingots under the protection of -0.5MPa argon;

[0048] (3) In a vacuum furnace, the ingot is homogenized and annealed at 950°C for 10 hours;

[0049] (4) hot forging the annealed button-shaped ingot at 850°C radially into a cake-shaped material with a thickness of 10 mm;

[0050] (5) Carry out cold rolling to the pie-shaped material that hot forging obtains, and the distortion of cold rolling is 50%-60%;

[0051] (6) Anneal the cold-rolled material at 800°C for 20 minutes;

[0052] (7) Step (5) and step (6) are repeated until a plate...

Embodiment 2

[0055] Embodiment 2: Preparation of Nb 54 Ti 26 Ni 20 memory alloy composite

[0056] (1) According to Nb content 54at.%, the ratio of Ti and Ni atomic ratio 1.3: 1 selects the niobium that purity is 99.9wt.%, the titanium that purity is 99.9wt.%, the nickel that purity is 99.9wt.%, wherein , the sum of the atomic percentages of Nb, Ti and Ni is 100%;

[0057] (2) Put the above-mentioned alloy components into a vacuum melting furnace, and melt them into ingots under the protection of -0.5MPa argon;

[0058] (3) Homogenize and anneal the smelted ingot at 950°C for 10 hours in a vacuum furnace;

[0059] (4) Hot forging the annealed ingot at 850°C into a rod-shaped material;

[0060] (5) At 470°C, hot-draw the hot-forged rod-shaped material;

[0061] (6) Step (5) is repeated until a wire with a diameter of 0.5 mm is obtained.

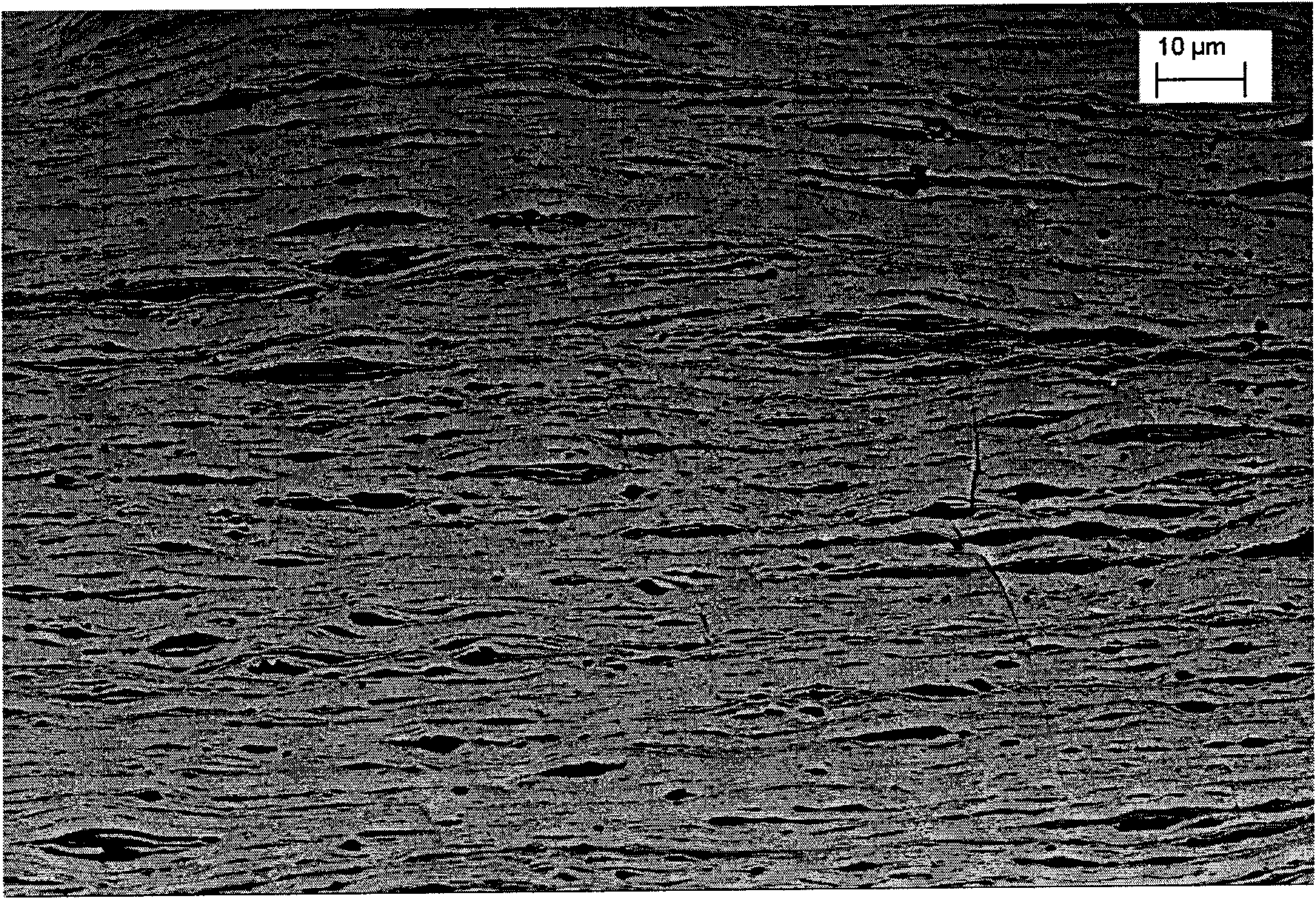

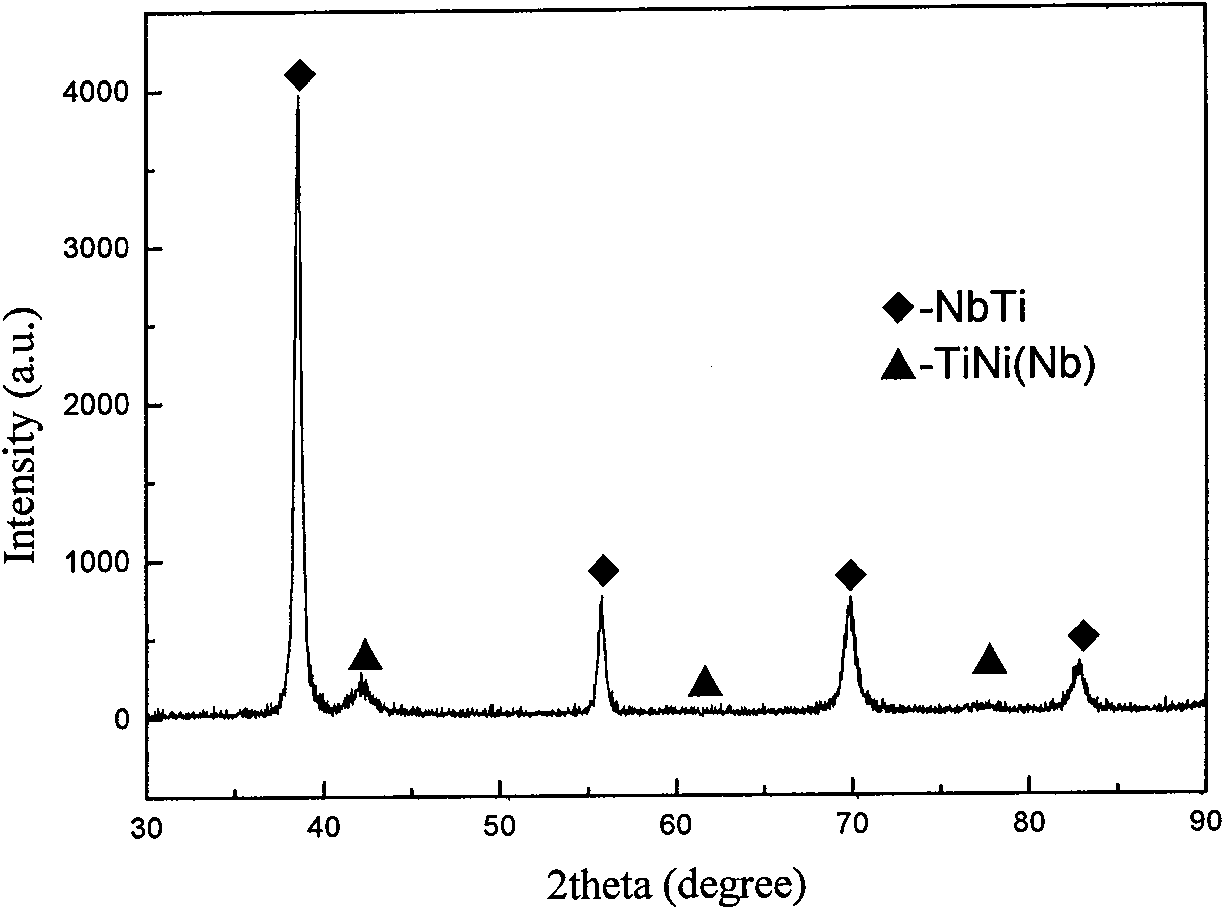

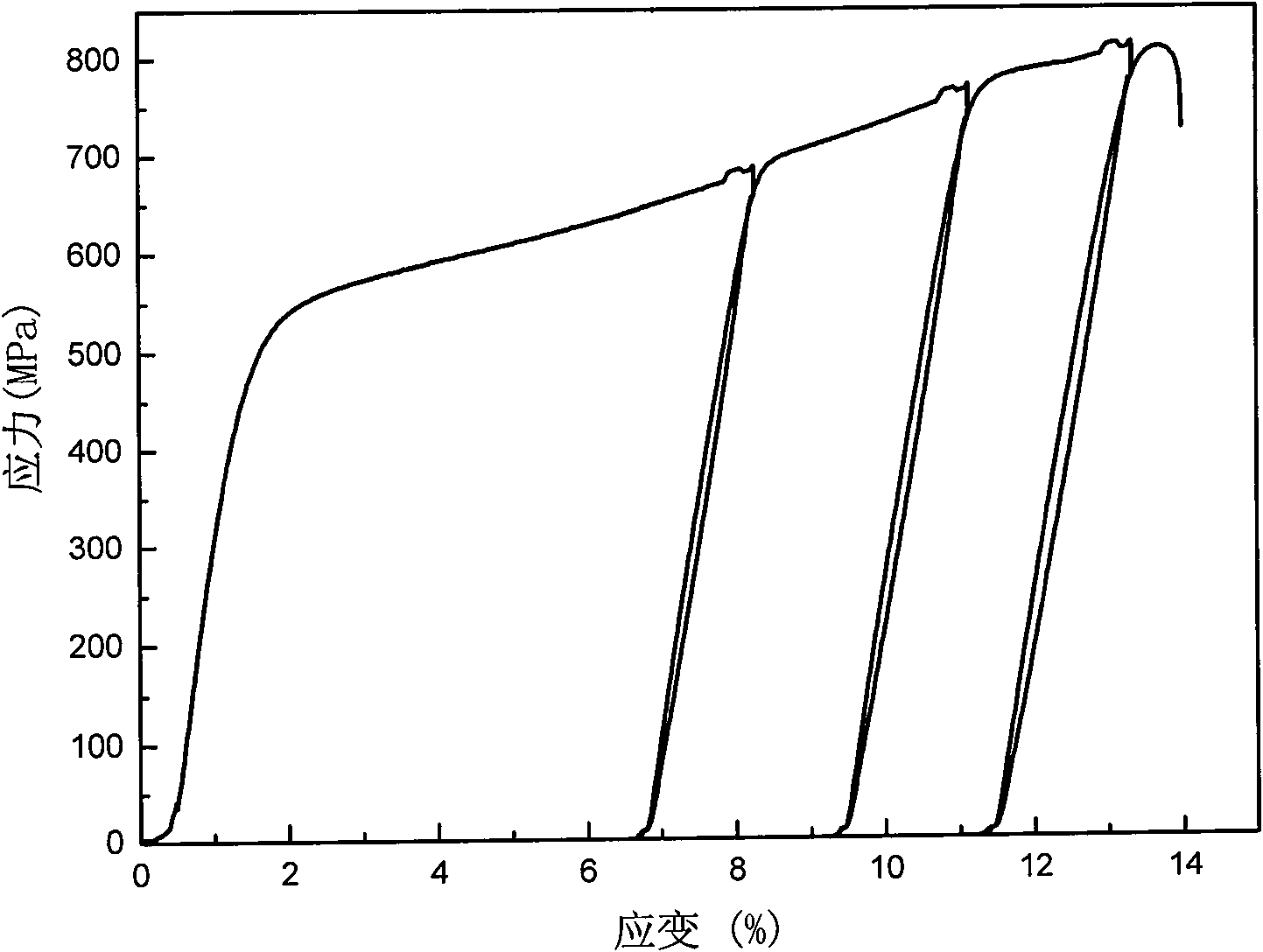

[0062] Cut off the 100mm long wire from the wire material obtained in step (6), after annealing at 400°C for 20min, observe the microstructure with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com