Preparation method of neodymium-doped titanium base tin dioxide-antimony electrode

A technology doped with tin dioxide and neodymium, which can be used in chemical instruments and methods, electrodes, electrolytic components, etc., and can solve problems such as complex components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

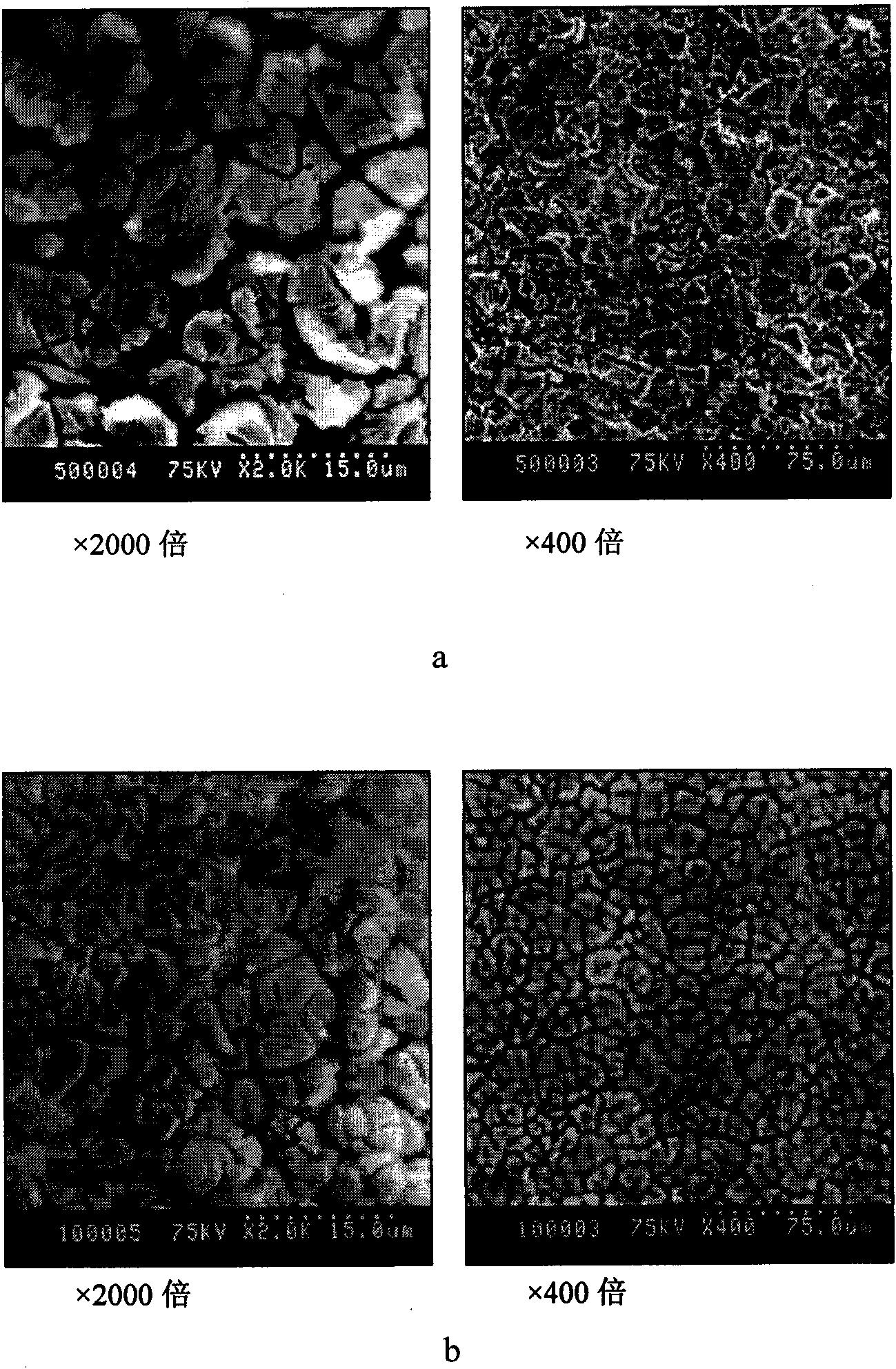

[0047] A kind of neodymium doped Ti / Sb-SnO 2 The preparation method of electrode, its preparation method is as follows:

[0048] 1) Electrode substrate pretreatment

[0049] The titanium wire specification of the electrode base titanium mesh is 1.5mm×1.0mm, the diamond mesh size is 3mm×8mm, and the pretreatment method is as follows:

[0050] (1) Grinding

[0051] First, mechanical polishing is used to remove oxides and dirt on the surface of the electrode substrate, and then the corners are polished with 600-grit sandpaper to make them smooth, and finally rinsed with deionized water;

[0052] (2) Alkaline washing

[0053] The whole electrode was immersed in 5% sodium carbonate (Na 2 CO 3 ) in the lotion, keep the pole pieces in a separated state, heat to boiling, keep for 1h, stop heating, cool, and rinse with deionized water;

[0054] (3) pickling

[0055] Submerge the entire electrode in oxalic acid washing solution with a mass concentration of 10%, treat it in a boil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com