Series connection type waste gas recycling cooler for medium and heavy duty vehicle

A technology of exhaust gas recirculation and cooler, which is applied in the direction of exhaust gas recirculation, machines/engines, and adding non-fuel substances to fuel, etc., to achieve the effects of reducing processing difficulty, reasonable layout, and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

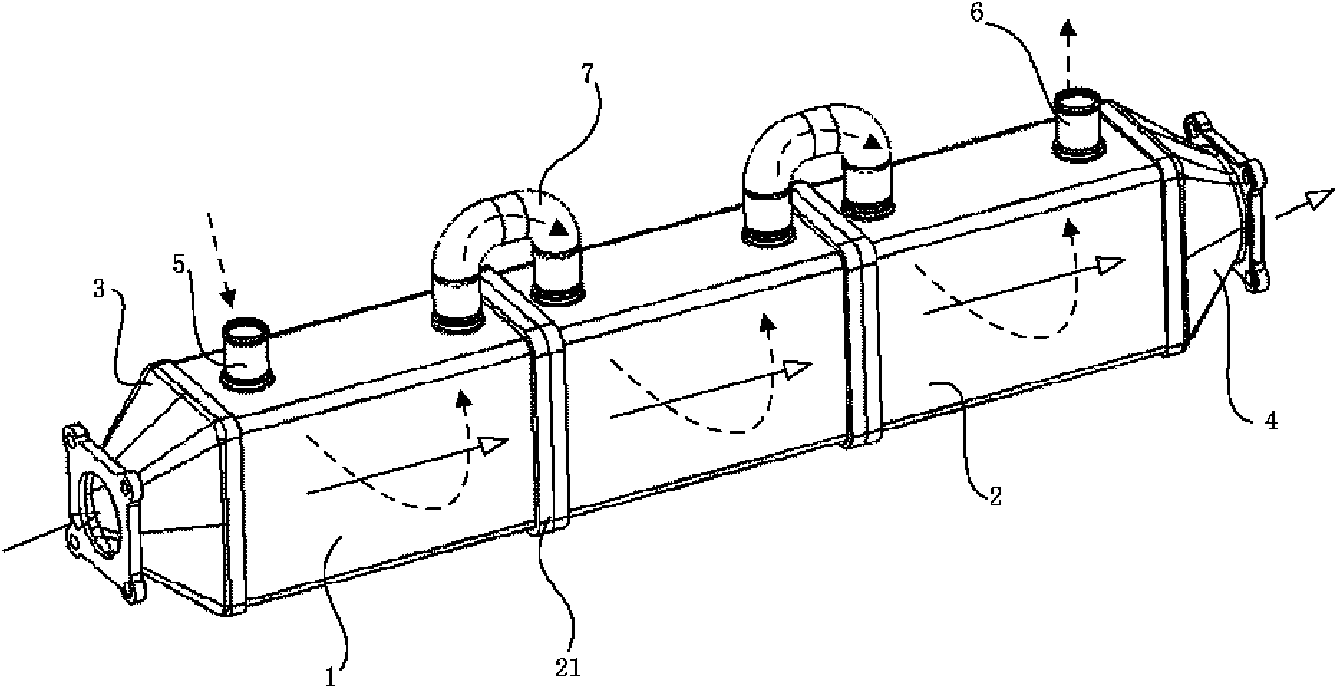

[0027] This embodiment is a series exhaust gas recirculation cooler for medium and heavy vehicles, including: an intake pipe box 3 connected to the engine exhaust pipe, an exhaust pipe box 4 connected to the intake pipe of the engine exhaust gas recirculation system, and an intake pipe box There are at least two heat exchange pipe assemblies connected to the exhaust pipe box respectively through ridge rings. The heat exchange pipe assembly 1 connected to the intake pipe box is provided with a water inlet pipe 5, and the heat exchange pipe assembly 1 connected to the air outlet pipe box The body assembly 2 is provided with a water outlet pipe 6 . The heat exchange tube assembly is connected through the heat exchange tube connector 21 connected to the air circuit, and connected to the water channel through the water channel connector 7 .

[0028] The heat exchanger described in this embodiment may consist of two heat exchange tube assemblies, or may be composed of three, four or...

Embodiment 2

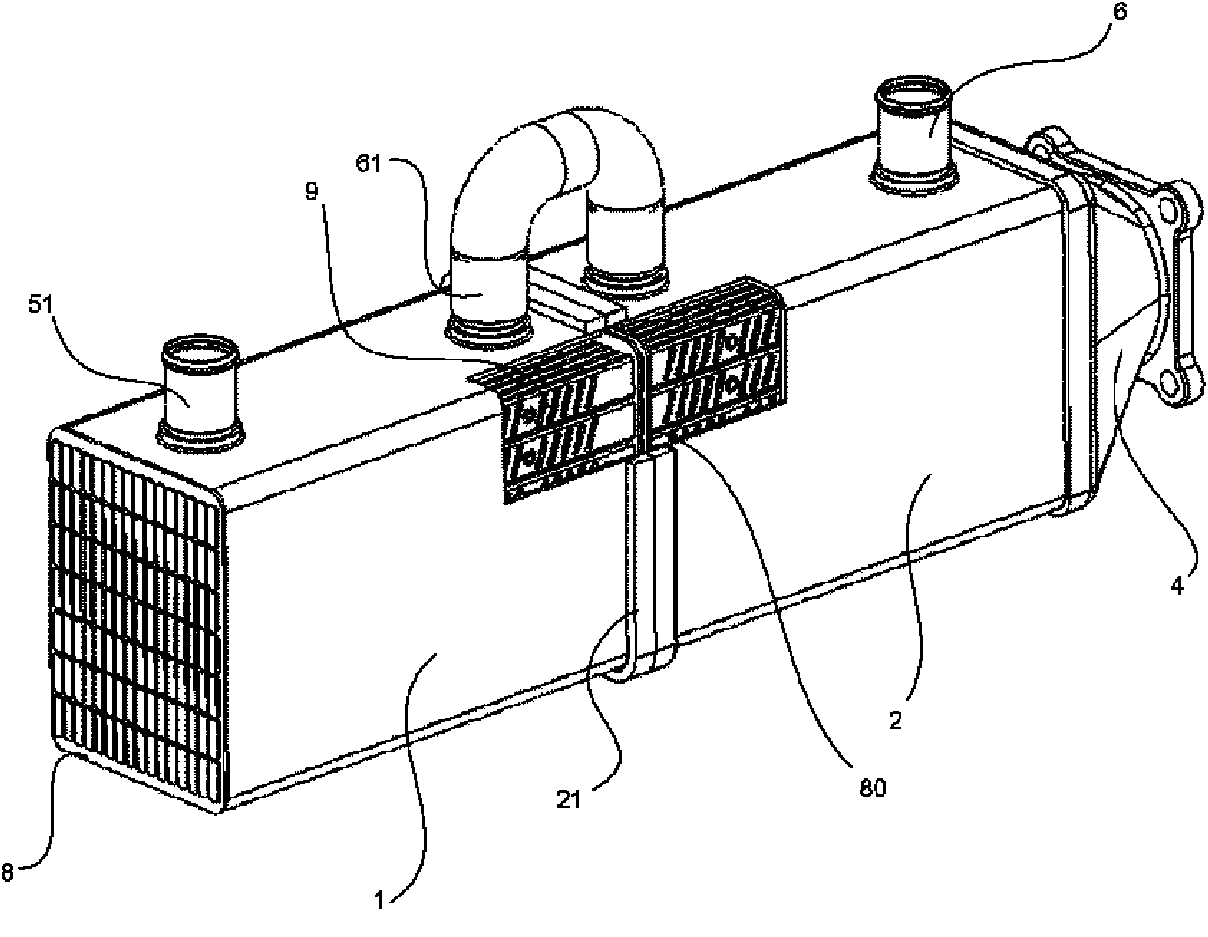

[0036] This embodiment is an improvement of Embodiment 1, and it is the refinement of Embodiment 1 on the heat exchange tube assembly, such as image 3 shown. The heat exchange tube body assembly described in this embodiment includes a tube shell 1 with a rectangular or circular cross-section surrounded by metal plates. End plates 8 are welded to the two ends of the shell opening, and a circulating exhaust gas is installed between the two end plates. A plurality of heat exchange tubes 9.

[0037] The heat exchange tube body assembly described in this embodiment is similar to a small heat exchanger, and also has tube shells, heat exchange tubes and tube sheets, and the tube sheets are called end plates for the sake of distinction. The cross-section of the heat exchange tube can have various shapes, which can be circular or flat, or elliptical and so on. The surface of the heat exchange tube may have inwardly recessed grooves to improve the heat exchange efficiency of the heat...

Embodiment 3

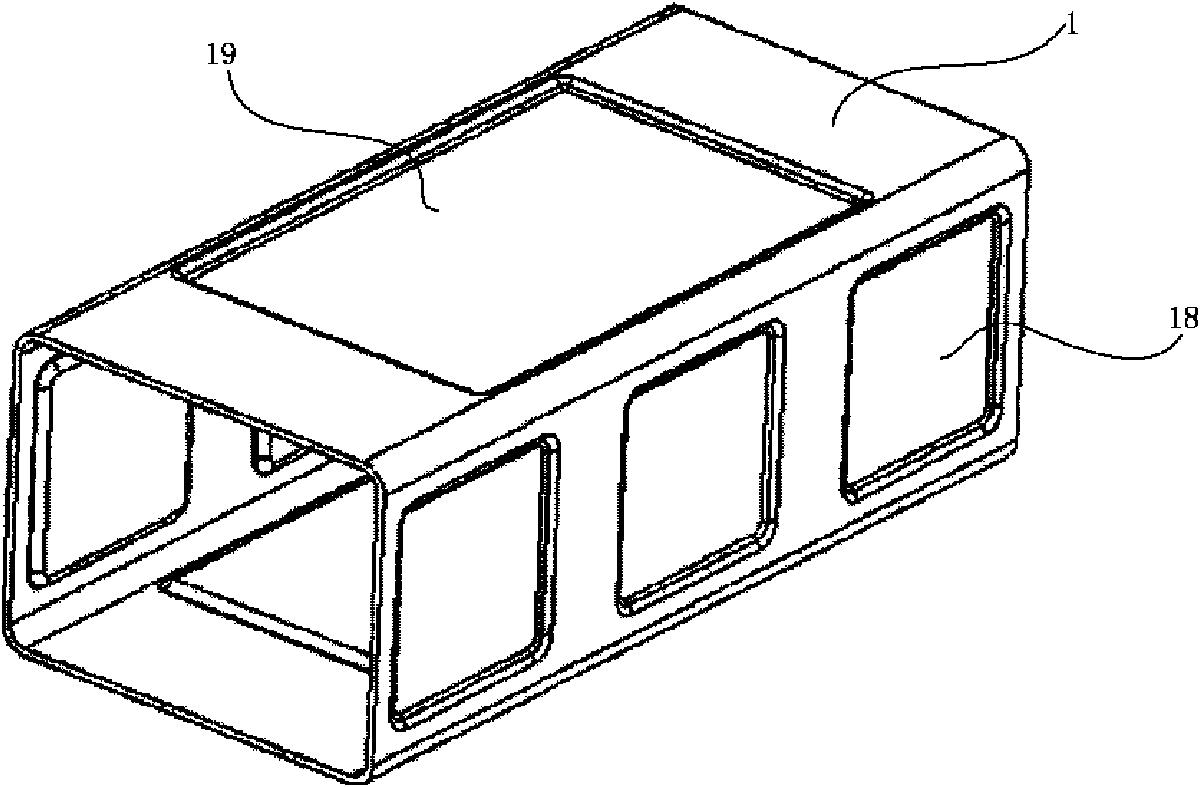

[0041] This embodiment is the refinement of embodiment two, and it is the refinement of embodiment two about the shell, such as Figure 4 , 5 shown. The tube shell described in this embodiment is surrounded by two sections of metal plates connected by a ridge ring.

[0042] The shell can be made of one piece of sheet metal or two pieces of sheet metal, either directly welded in between or joined using spine rings or flanged. In this embodiment, a ridge ring is used to connect the two shells 12 , 13 . The ridge ring 14 described in this embodiment is a metal ring with a shape corresponding to the shell and with a step on the end face of the shell. The shell with ridged ring resists thermal stress.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com