Catalyst combination process of sulfur recovering device

A sulfur recovery and catalyst technology, which is applied in physical/chemical process catalysts, chemical recovery, sulfur preparation/purification, etc., can solve the problems of high device operating costs, no economic benefits generated by the tail gas hydrogenation device, and large one-time investment. , to achieve the effect of improving the recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

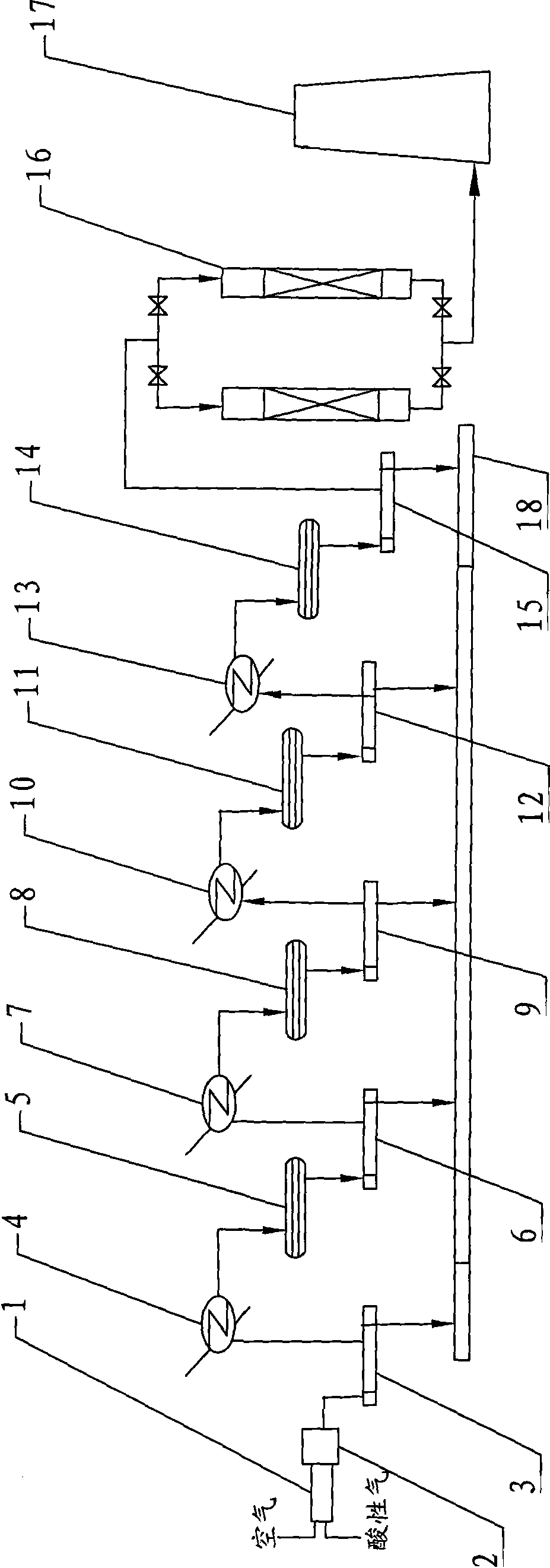

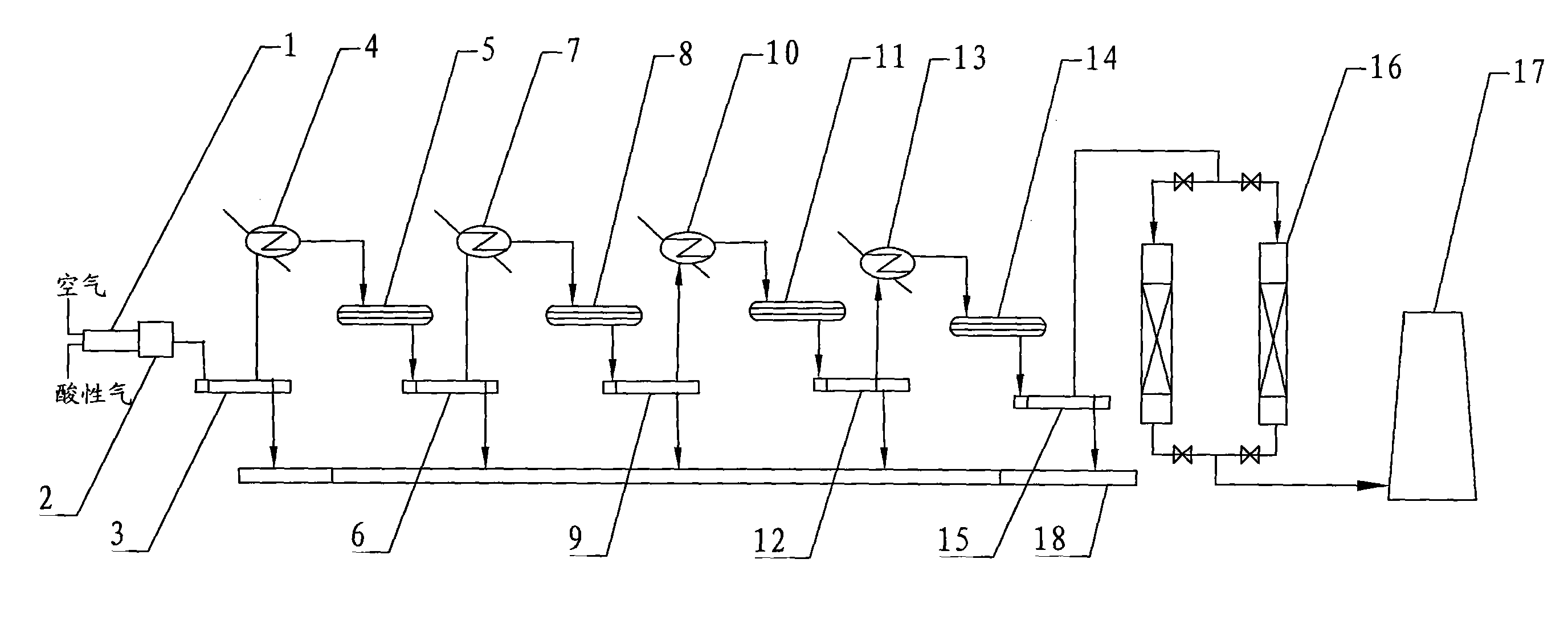

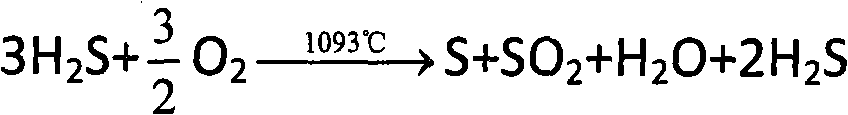

[0055] 1) Device connection: such as figure 1 As shown, a reduction-oxidation-absorption integrated sulfur recovery device includes a combustion furnace 1, a waste pot 2, a primary condenser 3, a primary reheater 4, a primary Claus reactor 5, The secondary condenser 6, the secondary reheater 7, the secondary Claus reactor 8, the tertiary condenser 9, the tertiary reheater 10, the selective hydrogenation reduction reactor 11, the quaternary condenser 12, Four-stage reheater 13, selective oxidation reactor 14, five-stage condenser 15, adsorption desulfurization tower 16 and vent chimney 17;

[0056] The first-stage condenser 3 , the second-stage condenser 6 , the third-stage condenser 9 , the fourth-stage condenser 12 , and the fifth-stage condenser 15 are connected to a liquid sulfur tank 18 .

[0057] The adsorption desulfurization tower 16 is connected in parallel with two devices.

[0058] 2) Process parameters: Catalyst loading scheme and operating conditions are shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com