A kind of silicon calcium phosphate nanopowder, preparation method and application

A technology of silicon calcium phosphate and nanopowder, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of decreased biological activity, difficult sintering of CPS powder, poor mechanical properties of ceramic materials, etc., and achieve the degree of reunion Low, easy to industrialized production, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The invention provides a preparation method of silicon calcium phosphate nanopowder, comprising the following steps:

[0048] (1) The calcium source is mixed with the first liquid phase dispersant to prepare a calcium source dispersion system, and then the silicon source is added dropwise to disperse evenly to obtain a calcium-silicon mixed liquid.

[0049]In this step, the calcium source is any one or more of easily soluble, soluble or slightly soluble calcium sources, for example, any one of calcium nitrate, calcium chloride, calcium phosphate, and calcium hydroxide can be selected. or more, preferably calcium hydroxide; the silicon source can be selected from commonly used silicon source reagents, more suitable are ethyl orthosilicate, silica sol, sodium silicate, calcium silicate, and the above-mentioned Any one or more of the silicon source reagents is preferably ethyl orthosilicate.

[0050] It should be noted that the above-mentioned easily soluble, soluble, and...

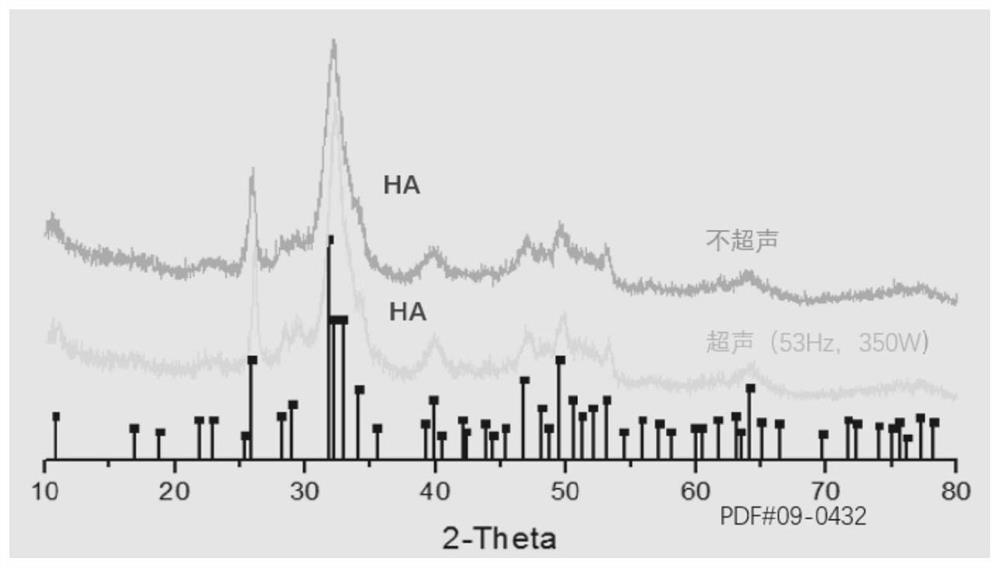

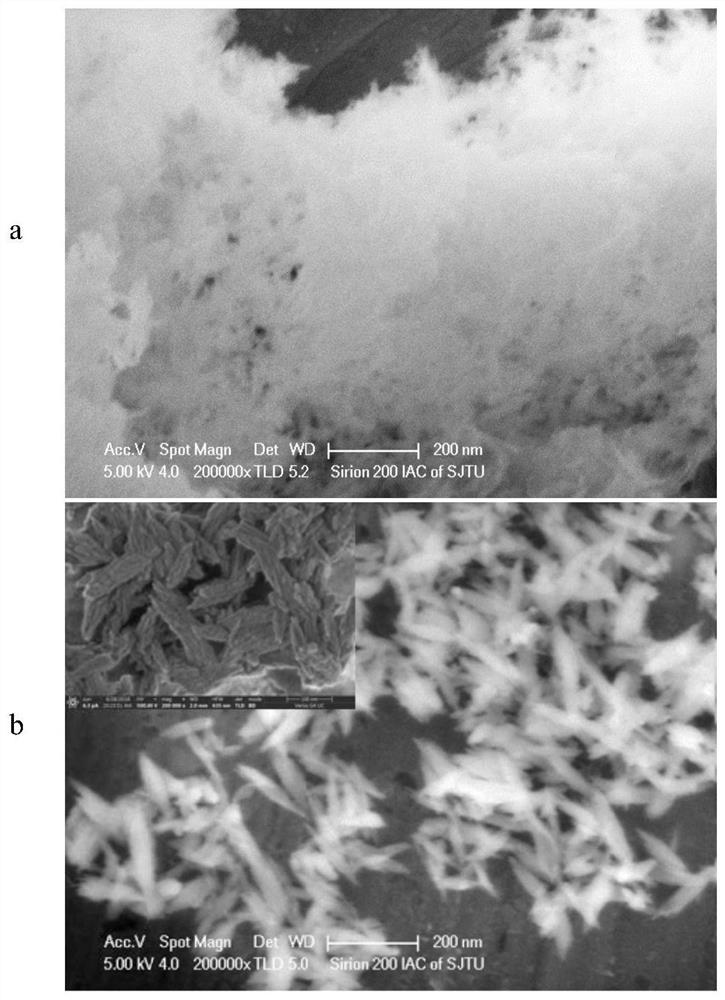

Embodiment 1

[0082] (1) Prepare Ca(OH) with a concentration of 0.5mol / L 2 Solution 500mL. Weigh 18.53 g of analytically pure calcium hydroxide powder into a beaker, add deionized water until the total volume of the solution is 500 mL, place the beaker in an ultrasonic device for full-power ultrasonication with mechanical stirring for 30 min, and obtain a highly dispersed suspension.

[0083] (2) Prepare H with a concentration of 0.2mol / L 3 PO 4 Solution 500mL. Measure 6.8mL of analytically pure H 3 PO 4 , diluted with deionized water to a total volume of 500mL, placed in an ultrasonic device and ultrasonically mixed evenly.

[0084] (3) Measure 11.2 mL of analytically pure tetraethyl orthosilicate (TEOS) and add it dropwise to Ca(OH) 2 The suspension was placed in an ultrasonic device for continuous ultrasonication and mechanical stirring for 1 hour to obtain a calcium-silicon mixture.

[0085] (4) After step (3), the H 3 PO 4 The solution was slowly added dropwise into the calciu...

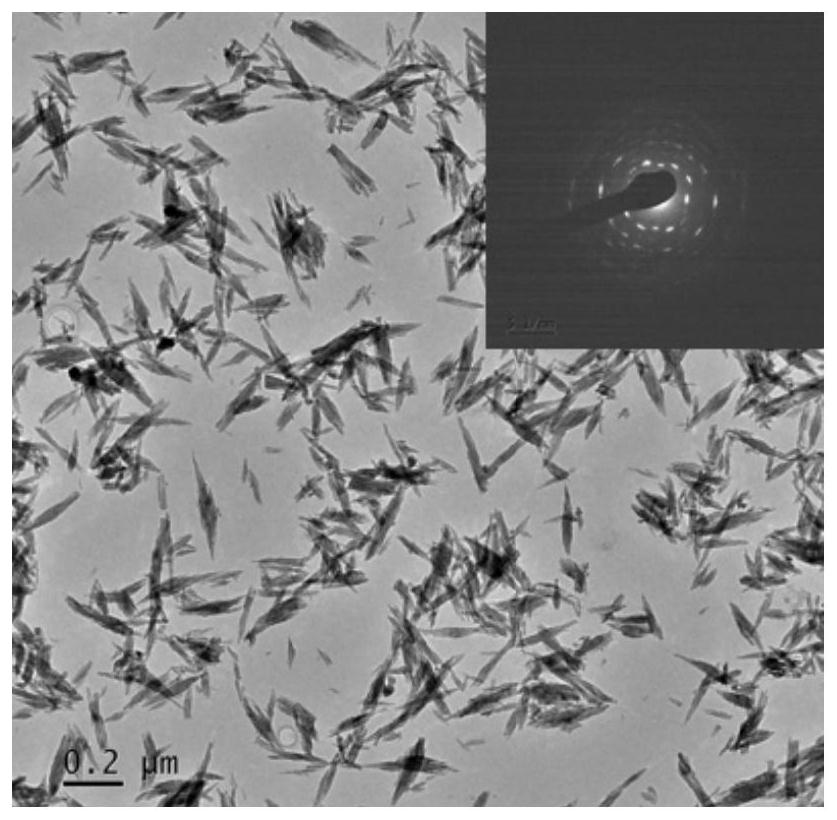

Embodiment 2

[0089] (1) With embodiment 1.

[0090] (2) With embodiment 1.

[0091] (3) with embodiment 1.

[0092] (4) After step (3), the H 3 PO 4 The solution was slowly added dropwise into the calcium and silicon mixed solution with a separatory funnel, and the mixed system was ultrasonically treated during the dropping process (H 3 PO 4 The solution dripping process lasted 27±2min), and continued ultrasonic treatment after the addition, wherein the ultrasonic power was 350W, the ultrasonic frequency was 53kHz, the total duration of ultrasonic treatment was 60min, and the temperature of the mixing system was maintained at 40-60°C. At the same time, ammonia water is used to control the pH of the solution between 10 and 11 without aging time.

[0093] (5) with embodiment 1.

[0094] (6) With embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com