Device and method for preparing butane diacid by continuously hydrolyzing dialkyl succinate ester

A technology of dialkyl succinate and succinic acid, applied in the preparation of carboxylate/lactone, organic chemistry, etc., can solve the problem of large sewage discharge, accelerated resin saturation, production scale and application constraints of succinic acid And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

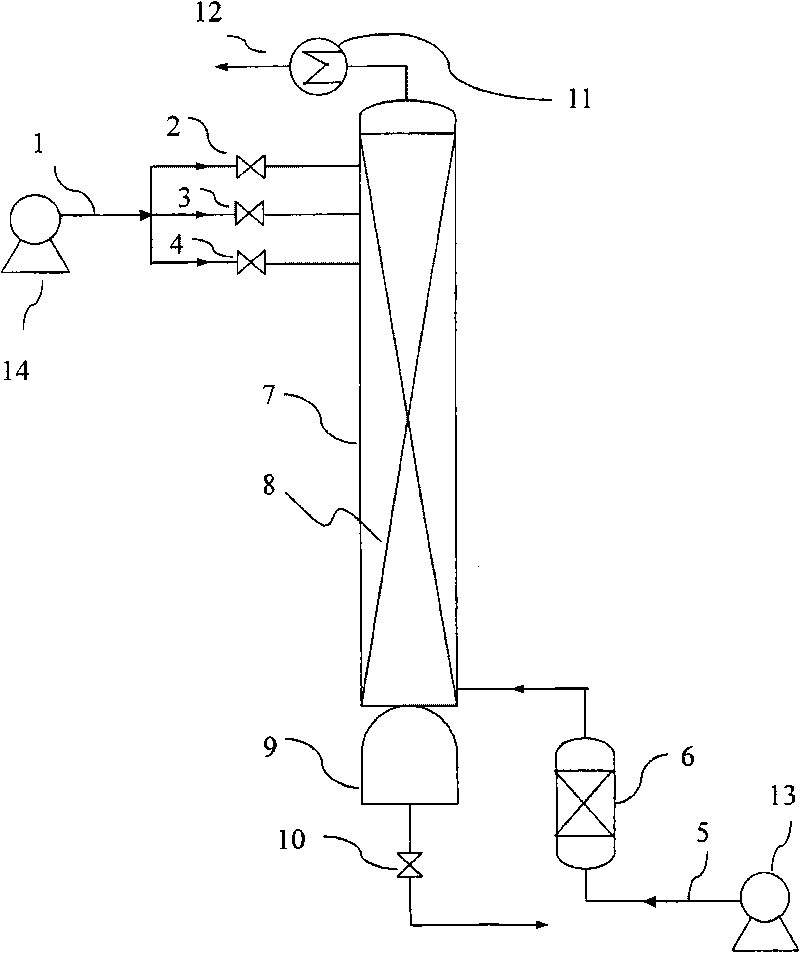

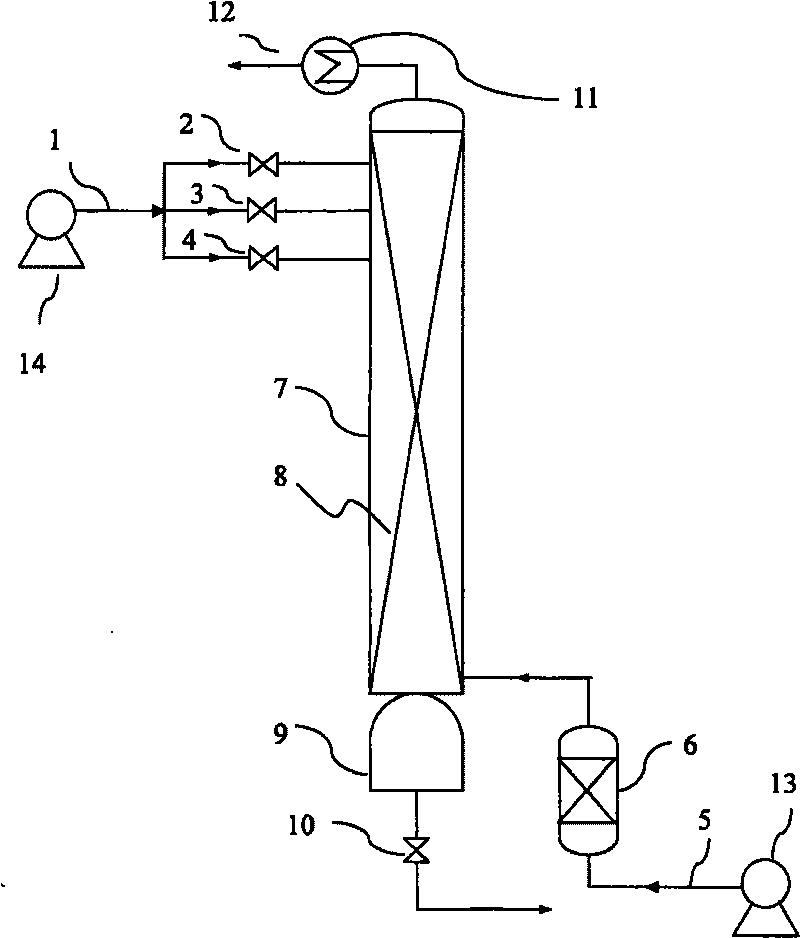

Method used

Image

Examples

Embodiment 1

[0035] The raw material is pure dibutyl 1,4-succinate

[0036] 1,4-dibutyl succinate inlet: 4

[0037] Reactive distillation tower temperature: 210°C

[0038] Reaction tower pressure: 1.9MPa

[0039] Reaction tower kettle temperature: 190°C

[0040] Steam generator temperature: 190°C

[0041] 1,4-dibutyl succinate conversion rate: close to 100%

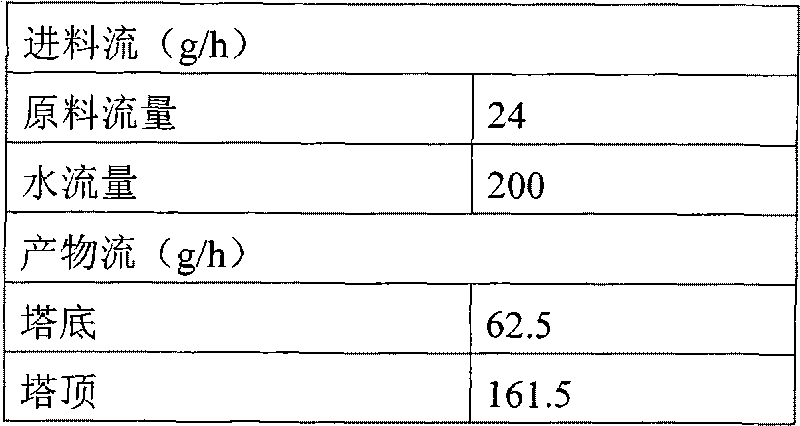

[0042]

[0043] The bottom stream composition (weight percent) at the bottom of the tower:

[0044] 1,4-dibutyl succinate: close to 0.0%

[0045] 1,4-Monobutyl succinate: close to 0.0%

[0046] 1,4-dibutyl succinate: 25.80%

[0047] Water: 74.20%

[0048] The top stream composition (percentage by weight) at the top of the tower:

[0049] Butanol: 6.43%

[0050] Water: 93.57%

Embodiment 2

[0052] The raw material is pure dibutyl 1,4-succinate

[0053] 1,4-dibutyl succinate inlet: 4

[0054] Reactive distillation tower temperature: 190°C

[0055] Reaction tower pressure: 1.2MPa

[0056] Reaction tower kettle temperature: 190°C

[0057] Steam generator temperature: 190°C

[0058] 1,4-dibutyl succinate conversion rate: close to 100%

[0059]

[0060] The bottom stream composition (weight percent) at the bottom of the tower:

[0061] 1,4-dibutyl succinate: close to 0.0%

[0062] 1,4-Monobutyl succinate: close to 0.0%

[0063] 1,4-Succinic acid: 22.94%

[0064] Water: 77.06%

[0065] The top stream composition (percentage by weight) at the top of the tower:

[0066] Butanol: 5.36%

[0067] Water: 94.64%

Embodiment 3

[0069] The raw material is pure dibutyl 1,4-succinate

[0070] 1,4-dibutyl succinate inlet: 3

[0071] Reactive distillation tower temperature: 190°C

[0072] Reaction tower pressure: 1.2MPa

[0073] Reaction tower kettle temperature: 190°C

[0074] Steam generator temperature: 190°C

[0075] 1,4-dibutyl succinate: close to 100%

[0076]

[0077] The bottom stream composition (weight percent) at the bottom of the tower:

[0078] 1,4-dibutyl succinate: close to 0.0%

[0079] 1,4-Monobutyl succinate: grade 0.0%

[0080] 1,4-Succinic acid: 48.58%

[0081] Water: 51.42%

[0082] The top stream composition (percentage by weight) at the top of the tower:

[0083] Butanol: 8.26%

[0084] Water: 91.74%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com