Method and device for preparing carboxylic acids by hydrolysis of polybasic carboxylic acid ester

A polycarboxylic acid ester and carboxylic acid ester technology, which is applied in the fields of chemistry, materials and mechanical science, can solve the problems of catalyst regeneration, replacement and recovery difficulties, and troublesome catalyst production and filling methods, so as to achieve the effect of excellent technical effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

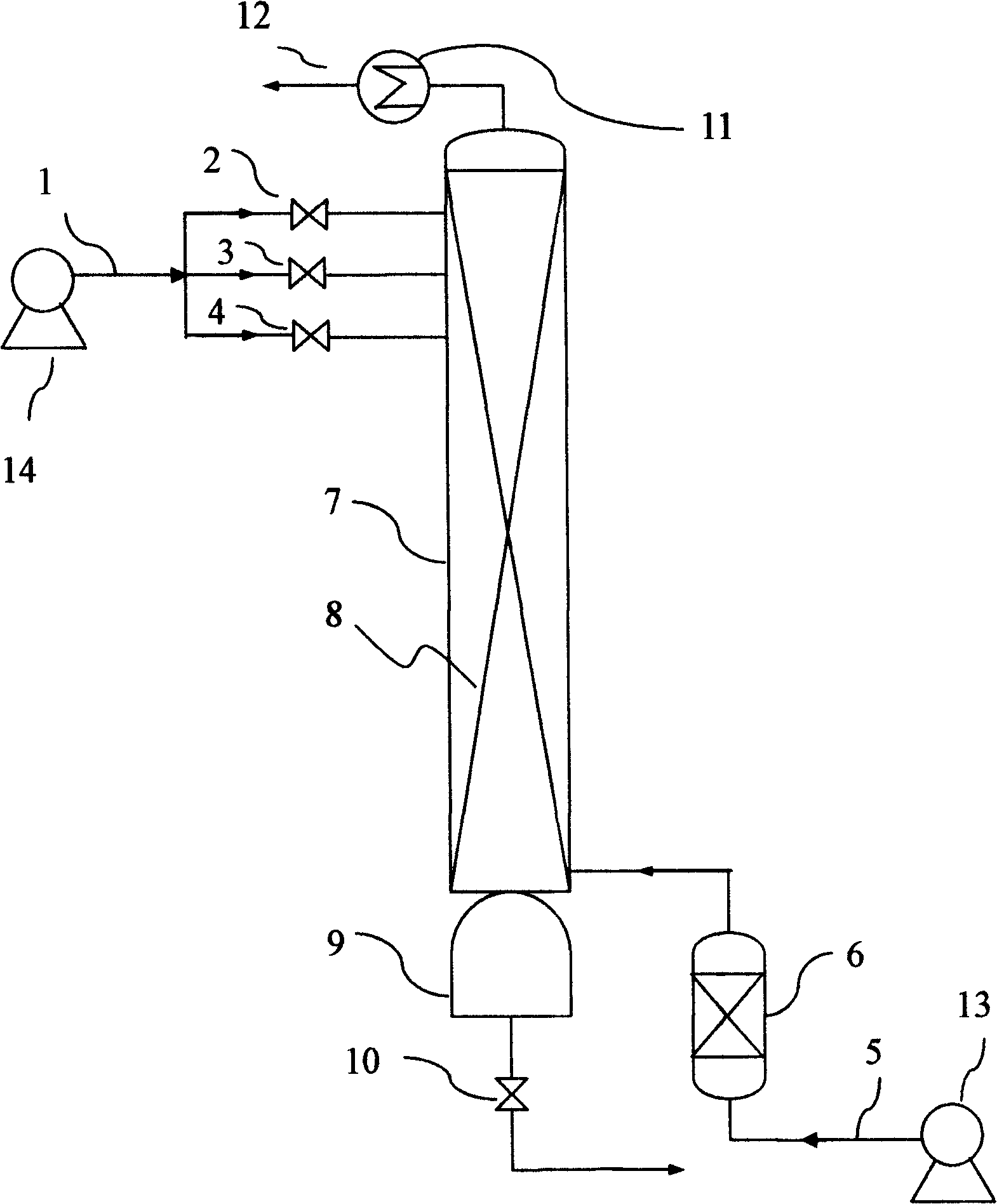

Image

Examples

Embodiment 1

[0077] The raw material is pure dimethyl 1,4-cyclohexanedicarboxylate

[0078] Carboxylate feed inlet: 4 (the number 4 refers to the number of feed inlets and the number of segments for segmented feeding)

[0079] Reactive distillation tower temperature: 200°C

[0080] Reaction tower pressure: 1.5MPa

[0081] Reactor tower kettle temperature: 165°C

[0082] Steam generator temperature: 170°C

[0083] Dimethyl 1,4-cyclohexanedicarboxylate conversion rate: 100%

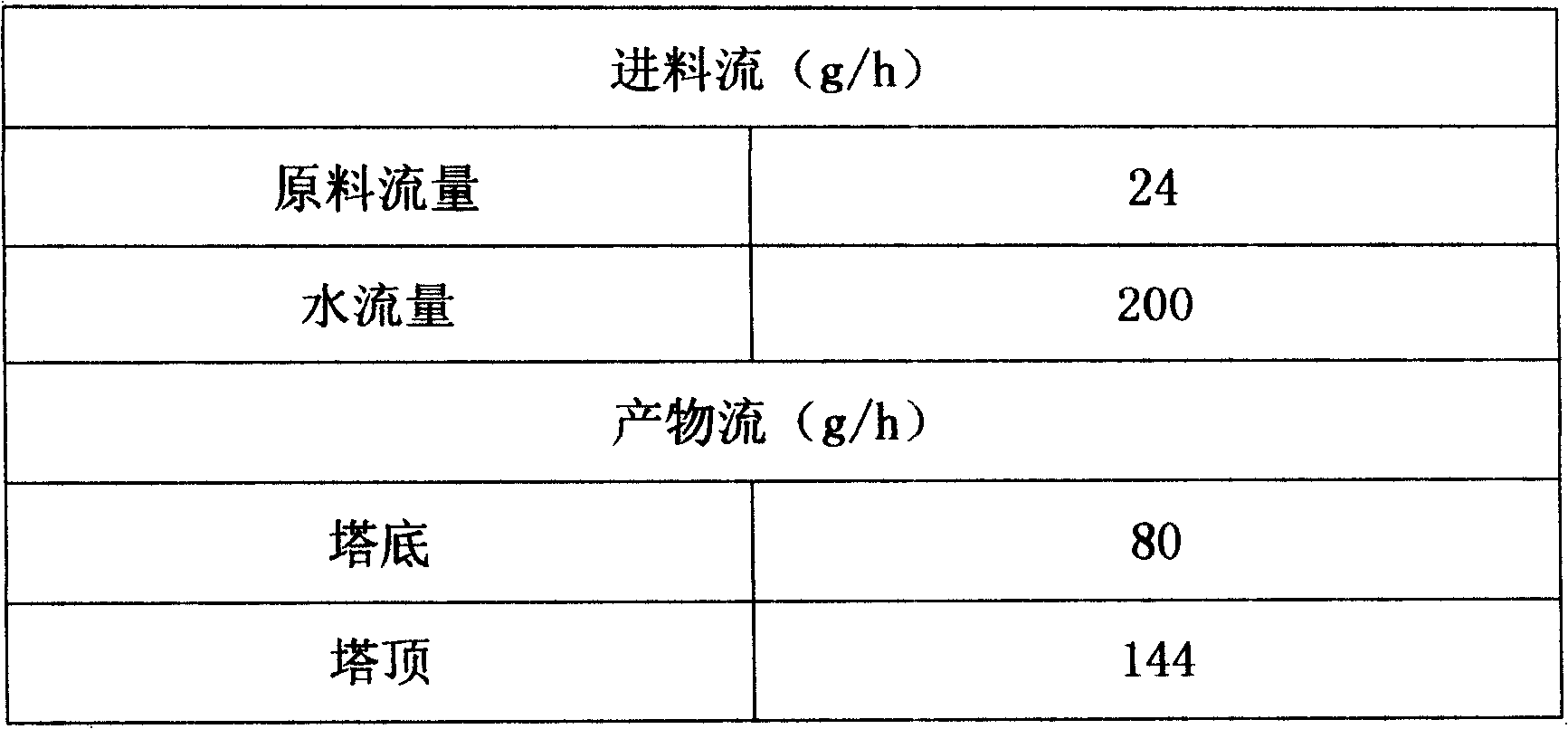

[0084]

[0085] The bottom stream composition (weight percent) at the bottom of the tower:

[0086] Dimethyl 1,4-cyclohexanedicarboxylate: 0.0%

[0087] 1,4-Cyclohexanedicarboxylic acid monomethyl ester: 0.0%

[0088] 1,4-Cyclohexanedicarboxylic acid: 25.80%

[0089] Water: 74.20%

[0090] The top stream composition (percentage by weight) at the top of the tower:

[0091] Methanol: 5.33%

[0092] Water: 94.67%.

Embodiment 2

[0094] The raw material is pure dimethyl 1,4-cyclohexanedicarboxylate

[0095] Carboxylate feed ports: 4

[0096] Reactive distillation tower temperature: 170°C

[0097] Reaction tower pressure: 0.80MPa

[0098] Reactor tower kettle temperature: 165°C

[0099] Steam generator temperature: 170°C

[0100] Dimethyl 1,4-cyclohexanedicarboxylate conversion rate: 100%

[0101]

[0102] The bottom stream composition (weight percent) at the bottom of the tower:

[0103] Dimethyl 1,4-cyclohexanedicarboxylate: 0.0%

[0104] 1,4-Cyclohexanedicarboxylic acid monomethyl ester: 0.0%

[0105] 1,4-Cyclohexanedicarboxylic acid: 22.94%

[0106] Water: 77.06%

[0107] The top stream composition (percentage by weight) at the top of the tower:

[0108] Methanol: 4.41%

[0109] Water: 95.59%.

Embodiment 3

[0110] Embodiment 3 (ester water ratio is 1: 6)

[0111] The raw material is pure dimethyl 1,4-cyclohexanedicarboxylate

[0112] Carboxylate feed ports: 3

[0113] Reactive distillation tower temperature: 170°C

[0114] Reaction tower pressure: 0.80MPa

[0115] Reactor tower kettle temperature: 165°C

[0116] Steam generator temperature: 170°C

[0117] Dimethyl 1,4-cyclohexanedicarboxylate conversion rate: 100%

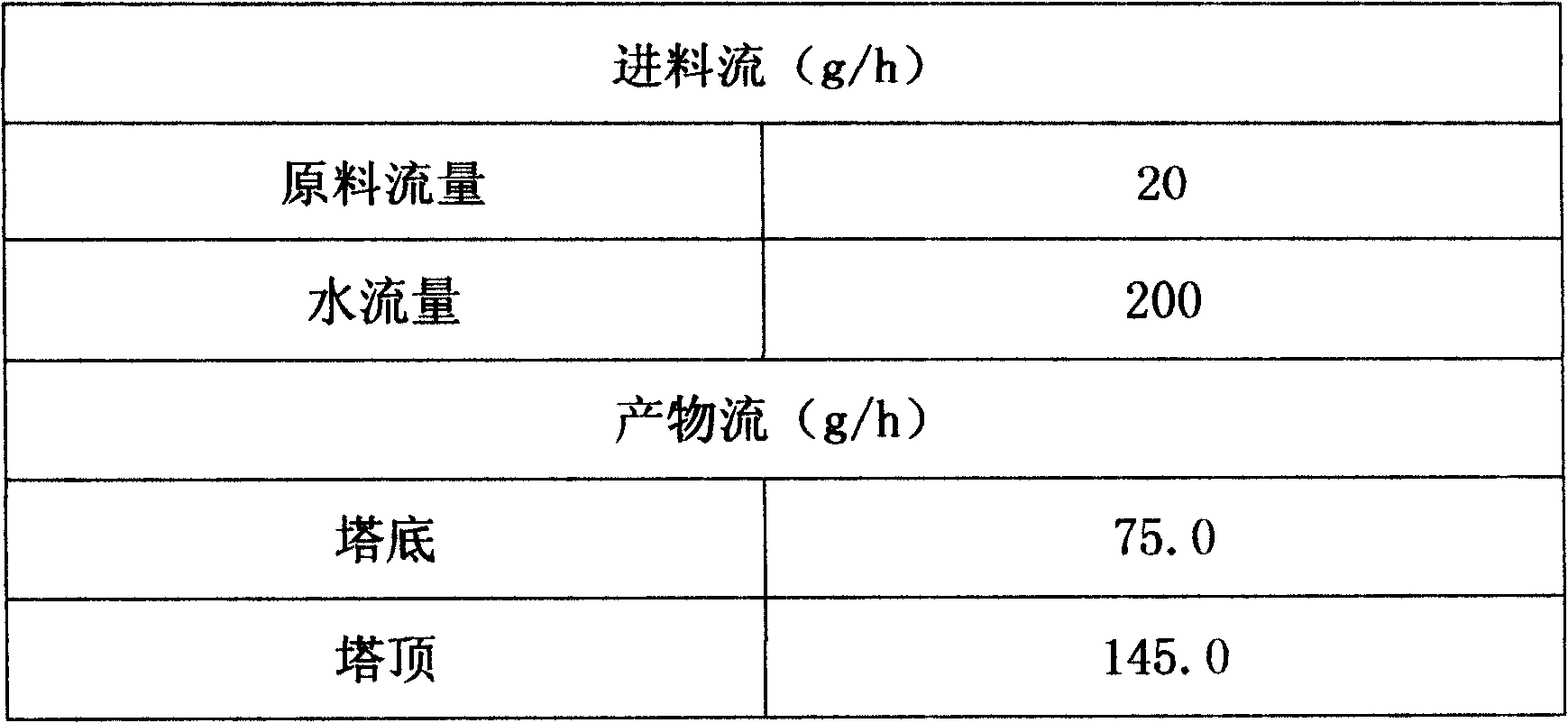

[0118]

[0119] The bottom stream composition (weight percent) at the bottom of the tower:

[0120] Dimethyl 1,4-cyclohexanedicarboxylate: 0.0%

[0121] 1,4-Cyclohexanedicarboxylic acid monomethyl ester: 0.0%

[0122] 1,4-Cyclohexanedicarboxylic acid: 48.58%

[0123] Water: 51.42%

[0124] The top stream composition (percentage by weight) at the top of the tower:

[0125] Methanol: 6.59%

[0126] Water: 93.41%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com