Low-temperature impact-resistant polypropylene composition, and preparation method and application thereof as decoration in automobile

A polypropylene composition and low-temperature-resistant technology, which is applied in the field of automotive interior parts, can solve the problems of not being able to obtain low-temperature-resistant and high-performance automotive instrument interior parts, not meeting automotive materials, and poor rigidity, etc., to achieve good cantilever Beam notched impact strength and multiaxial impact strength, the effect of overcoming poor low temperature performance, and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

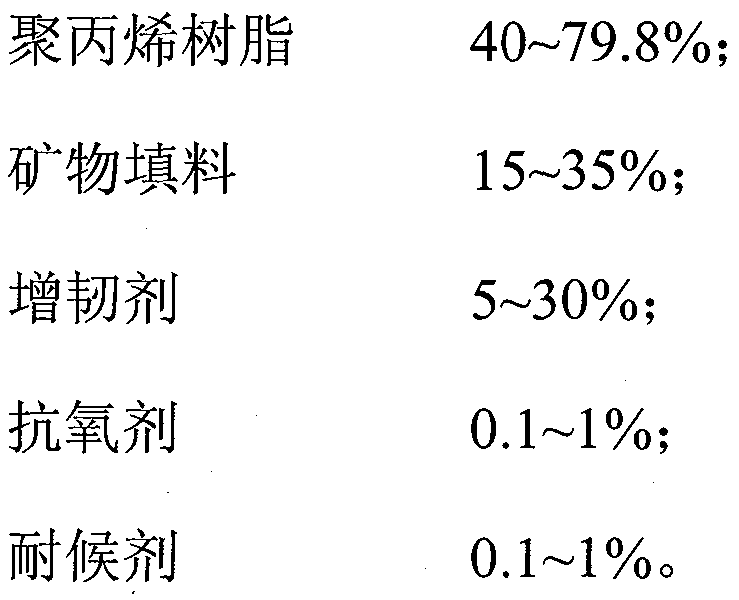

Method used

Image

Examples

Embodiment 1

[0035] Example 1 Low temperature impact resistant polypropylene composition

[0036] The composition of the polypropylene composition of this embodiment is shown in Table 1.

[0037] Table 1 Raw materials and consumption of polypropylene composition

[0038] raw material name

Dosage%

(weight percent) Polypropylene copolymer: HHP6, Sinopec Maoming Petrochemical Branch 65.4 Talc powder: Heshan Chemical Group 22 Toughener: POE, density 0.868g / cm 3 , ExxonMobil Chemical 12 Antioxidant: tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]

Pentaerythritol (Irganox1010), Ciba Fine Chemical Industry Co., Ltd. 0.2

Weather resistance agent: 4-benzoyloxy-2,2,6,6 tetramethylpiperidine (light stable 0.2

[0039] Agent 744), Ciba Fine Chemical Industry Co., Ltd. Calcium stearate 0.2

[0040] The polypropylene composition of the present embodiment, its preparation method is as follows:

[0041] The raw...

Embodiment 2

[0045] Example 2 Low temperature impact resistant polypropylene composition

[0046] The composition of the polypropylene composition of this embodiment is shown in Table 3.

[0047] Raw material and consumption of table 3 polypropylene composition

[0048] raw material name Dosage %

[0049] (weight percent) Polypropylene copolymer: SP179, Sinopec Qilu Petrochemical Company 67.4 Talc powder: Guangxi Hezhou Talc Powder Co., Ltd. 22 Toughener: POE, density 0.870g / cm 3 , ExxonMobil Chemical 10 Antioxidant: Tris(2,4-di-tert-butylphenyl)phosphite (Irganox

168), Ciba Fine Chemical Industry Co., Ltd. 0.2

Weather resistance agent: bis(1,2,2,6,6-pentamethyl-4-piperidinyl) sebacate

(Tinuvin292), Ciba Fine Chemical Industries Ltd. 0.2

[0050] The polypropylene composition of this embodiment, its preparation method is as embodiment 1.

[0051] The detection results of the polypropylen...

Embodiment 3

[0054] Example 3 Low temperature impact resistant polypropylene composition

[0055] The composition of the polypropylene composition for automotive interior parts of this embodiment is shown in Table 5.

[0056] Raw material and consumption of table 5 polypropylene composition

[0057] raw material name

Dosage%

(weight percent) Polypropylene copolymer: K7726, Sinopec Yanshan Petrochemical Branch 66.4 Talc powder: Heshan Chemical Group 25 Toughener: POE, density 0.868g / cm 3 , Dow Chemical 8 Antioxidant: tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propane

Acid] Pentaerythritol (Irganox1010), Ciba Fine Chemical Industry Co., Ltd.

limited company 0.2

Weather resistance agent: 4-benzoyloxy-2,2,6,6 tetramethylpiperidine (light

Stabilizer 744), Ciba Fine Chemical Industry Co., Ltd. 0.2

[0058] The polypropylene composition of this embodiment, its preparation method is as embodiment 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com