Method of double-element delta doped growth P-type GaN base material

A technology of base materials and elements, applied in the field of preparation of GaN materials, can solve the problems that are not enough, can not meet the requirements of devices well, difficult to obtain high-quality, high hole concentration P-type GaN-based materials, etc., and achieve self-compensation inhibition. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The present invention adopts metal-organic chemical vapor deposition (MOCVD) method to grow the substrate, low-temperature buffer layer, high-temperature buffer layer and GaN-based material. Surface sapphire substrate, the surface roughness is less than 0.1nm.

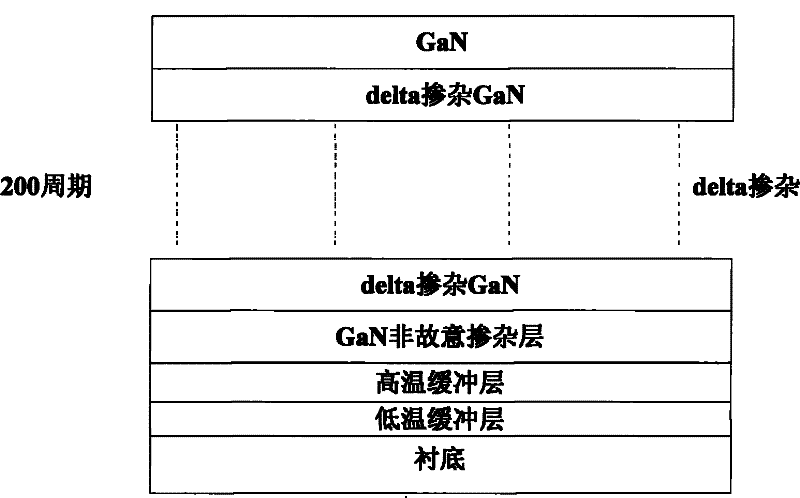

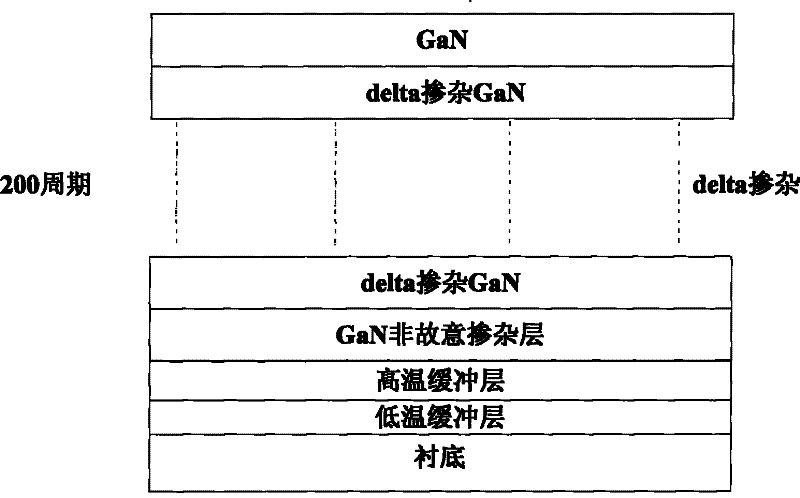

[0025] Such as figure 1 and figure 2 shown, using NH 3 , TMGa as N source and Ga source respectively, using H 2 As a carrier gas, the sapphire substrate is first heated to 550°C in the MOCVD reaction chamber, and a low-temperature buffer layer of 0.1um is grown on the sapphire substrate, and the material is GaN. Next, the temperature of the sapphire substrate is heated to 1050° C., and a high-temperature buffer layer of 1 μm is grown on the low-temperature buffer layer, and the material is GaN.

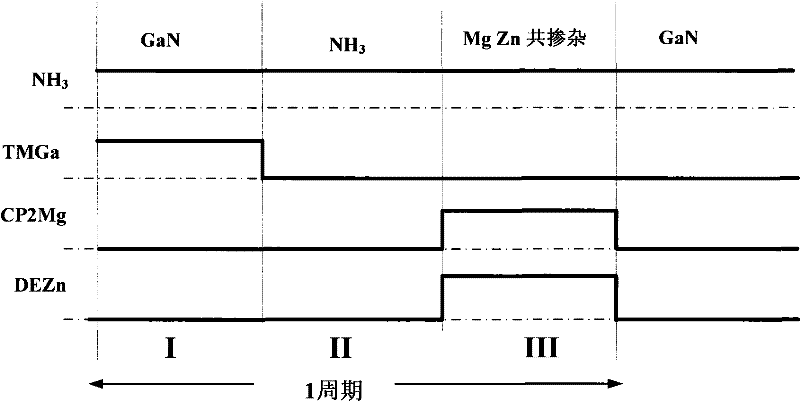

[0026] Secondly, keep the temperature of the sapphire substrate at 1050°C, and grow P-type GaN material for 200 cycles on the upper surface of the high-temperature buffer layer using the double-element delta doping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com