p-type algan semiconductor material growth method

A growth method and semiconductor technology, applied in the fields of semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve unfavorable large-scale production and commercial applications, cannot improve the donor compensation effect, cannot increase the magnesium doping concentration, etc. problems, to achieve the effect of improving the interface roughness, reducing the incorporation, and increasing the probability of incorporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

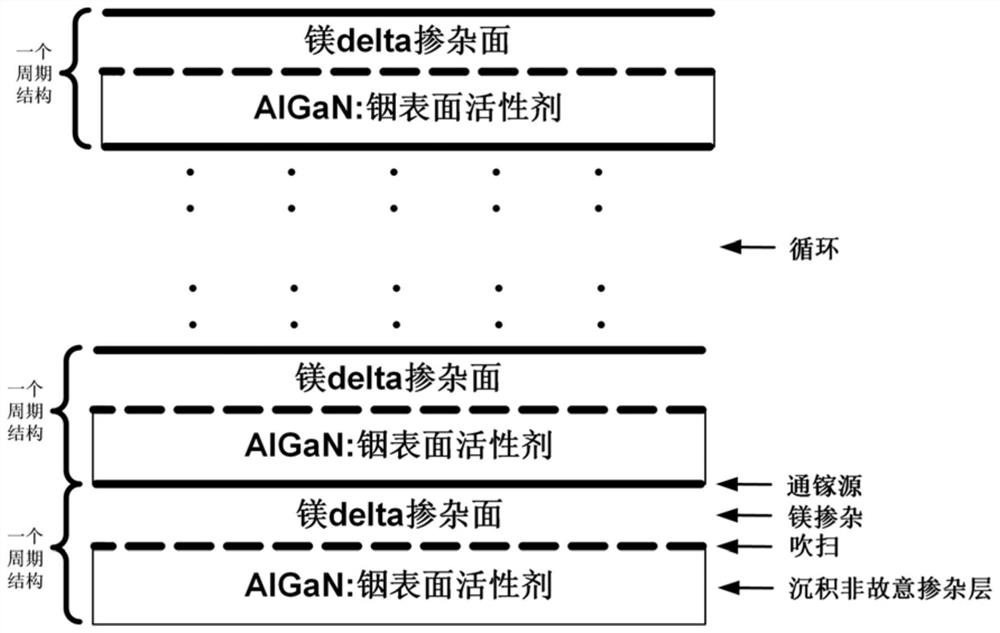

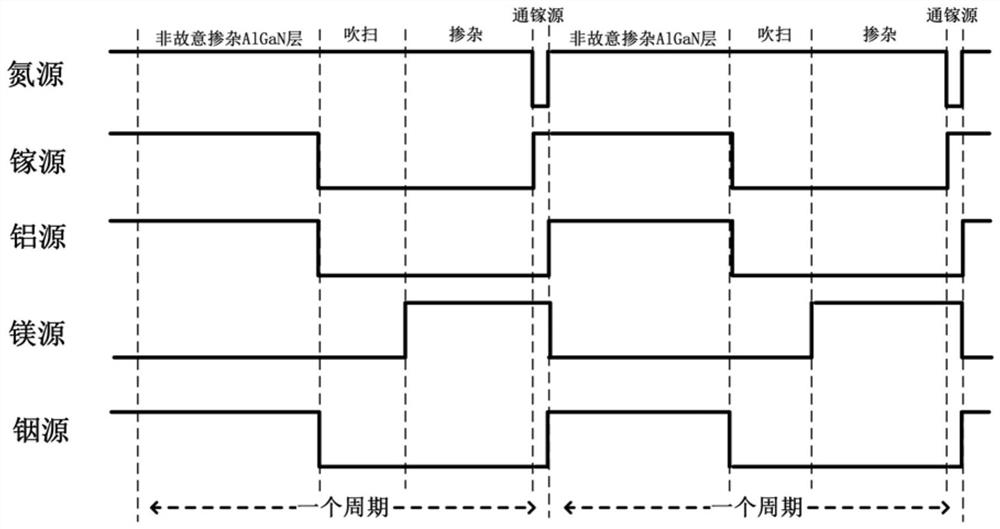

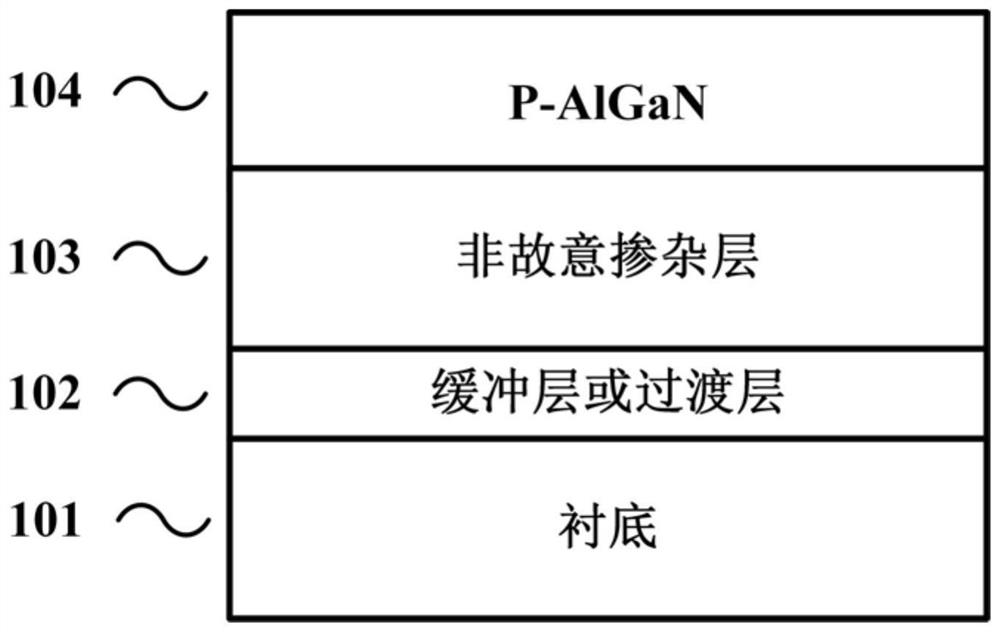

[0044] Such as image 3 As shown, the epitaxial growth structure of the p-type AlGaN semiconductor material of the present invention includes a substrate 101 , a buffer layer or transition layer 102 , an unintentionally doped layer 103 and an acceptor doped layer (p-type AlGaN semiconductor material layer) 104 . The substrate 101 is a sapphire substrate, a buffer layer 102 is grown on the substrate 101 by a metal organic chemical vapor deposition (MOCVD) epitaxial growth method, and a buffer layer 102 is grown on the buffer layer by a metal organic chemical vapor deposition (MOCVD) epitaxial growth method. The method grows an unintentionally doped AlGaN layer 103 and grows a p-type AlGaN semiconductor material layer 104 on the unintentionally doped AlGaN layer 103 by metal organic chemical vapor deposition (MOCVD) epitaxial growth method.

[0045] In the growth process of this implementation case, ammonia gas is used as the source of group V nitrogen; trimethylgallium is used ...

Embodiment 2

[0057] Such as image 3 As shown, the epitaxial growth structure of the p-type AlGaN semiconductor material of the present invention includes a substrate 101 , a buffer layer or transition layer 102 , an unintentionally doped layer 103 and an acceptor doped layer (p-type AlGaN semiconductor material layer) 104 . The substrate 101 is a silicon carbide substrate, and a buffer layer 102 is sequentially grown on the substrate 101 by a metal organic chemical vapor deposition (MOCVD) epitaxial growth method, and a metal organic chemical vapor deposition (MOCVD) epitaxy method is used on the buffer layer to grow The growth method grows the unintentionally doped AlGaN layer 103 and grows the p-type AlGaN semiconductor material layer 104 on the unintentionally doped AlGaN layer 103 by metal organic chemical vapor deposition (MOCVD) epitaxial growth method.

[0058] In the growth process of this implementation case, dimethylhydrazine nitrogen is used as the source of group V nitrogen; t...

Embodiment 3

[0070] The p-type AlGaN semiconductor material in this embodiment is grown on the AlN material substrate layer with a thickness of 500nm and a growth temperature of 900°C. In the growth process of this embodiment, ammonia gas is used as the source of Group V nitrogen; Gallium-based is used as the source of Group III gallium, and trimethylaluminum is used as the source of Group III aluminum; trimethylindium is used as a surfactant, which specifically includes the following steps:

[0071] Deposition of unintentionally doped AlGaN layer: use hydrogen as the carrier gas, keep the V-group nitrogen source continuously fed, pass through the III-group gallium source, the III-group aluminum source and the triethylindium surfactant, and deposit unintentionally doped AlGaN layer;

[0072] Purge: use hydrogen as the carrier gas, keep the V-group nitrogen source continuously fed, disconnect the III-group gallium source, III-group aluminum source and surfactant for 40s, and purge the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com