Cold-working molding method of thin-diameter thin-wall aluminum alloy tubular product

A technology of thin-walled pipes and aluminum alloy pipes, which is applied in the field of cold forming of aluminum alloy thin-diameter thin-walled pipes, to achieve the effects of simple processing steps, good surface quality, and small grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

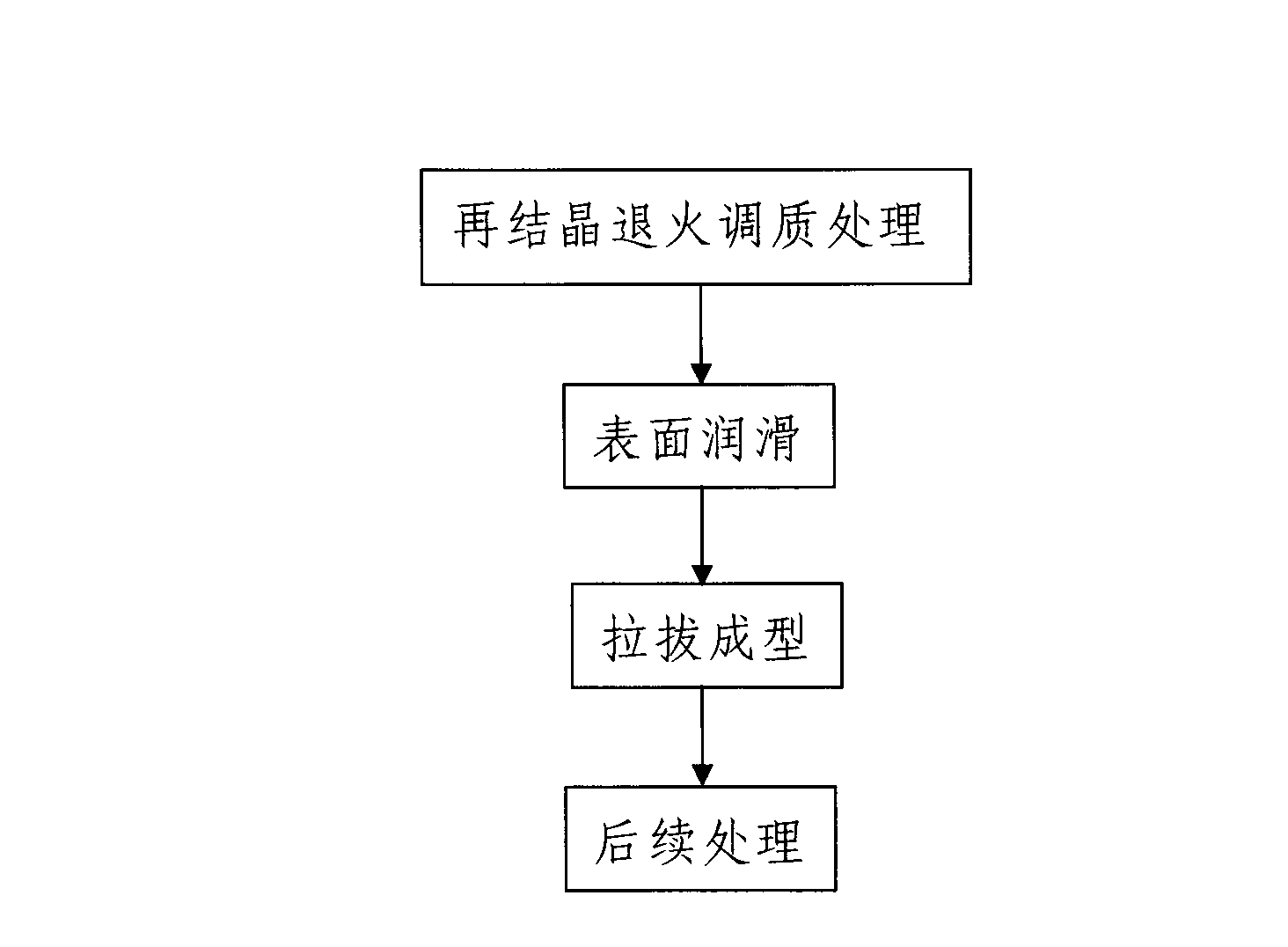

Embodiment 1

[0036] In this embodiment, the aluminum alloy 3A21 pipe material with a structural size of Φ7.5×0.75mm, that is, the aluminum alloy tube blank 1, needs to be cold-processed to Φ6.0×0.60mm. The specific processing process is as follows: first, the aluminum alloy 3A21 The pipe is subjected to recrystallization annealing and tempering treatment, and the heat treatment temperature is 450°C±50°C, the time is 60±30min, the cooling method is furnace cooling, and the average grain size after quenching and tempering is about 20μm. After conditioning treatment, the MoS 2 The emulsion lubricant is evenly coated on the outer surface of the aluminum alloy 3A21 pipe, and it is air-dried at room temperature. At the same time, a Φ4.8mm spring steel long core rod is inserted inside the aluminum alloy 3A21 pipe to be processed, and the deformation of each pass is set. ε is in the range of 8 to 25%. Afterwards, the first die uses a drawing die with a hole diameter of Φ7.0mm, and the aluminum al...

Embodiment 2

[0039] In this embodiment, the aluminum alloy 5052 narrow-diameter thin-walled pipe with a structural size of Φ5×0.3mm, that is, the aluminum alloy tube blank 1, needs to be cold-processed to Φ4×0.3mm. The specific processing process is as follows: The furnace performs recrystallization annealing quenching and tempering treatment on the aluminum alloy 5052 thin-diameter thin-walled pipe, and the heat treatment temperature is 500°C±50°C, the time is 120min±60min, and the cooling method is air cooling. After recrystallization annealing and tempering treatment, the MoS 2 The emulsion lubricant is evenly coated on the outer surface of the aluminum alloy 5052 thin-diameter and thin-walled pipe, and dried at a temperature of 50°C, and the deformation amount ε per mold pass is set at 8-20%. Afterwards, the first die uses a drawing die with a hole diameter of Φ4.6mm, and the aluminum alloy 5052 thin-diameter thin-walled pipe to be processed passes through the hole of a YG8 hard alloy ...

Embodiment 3

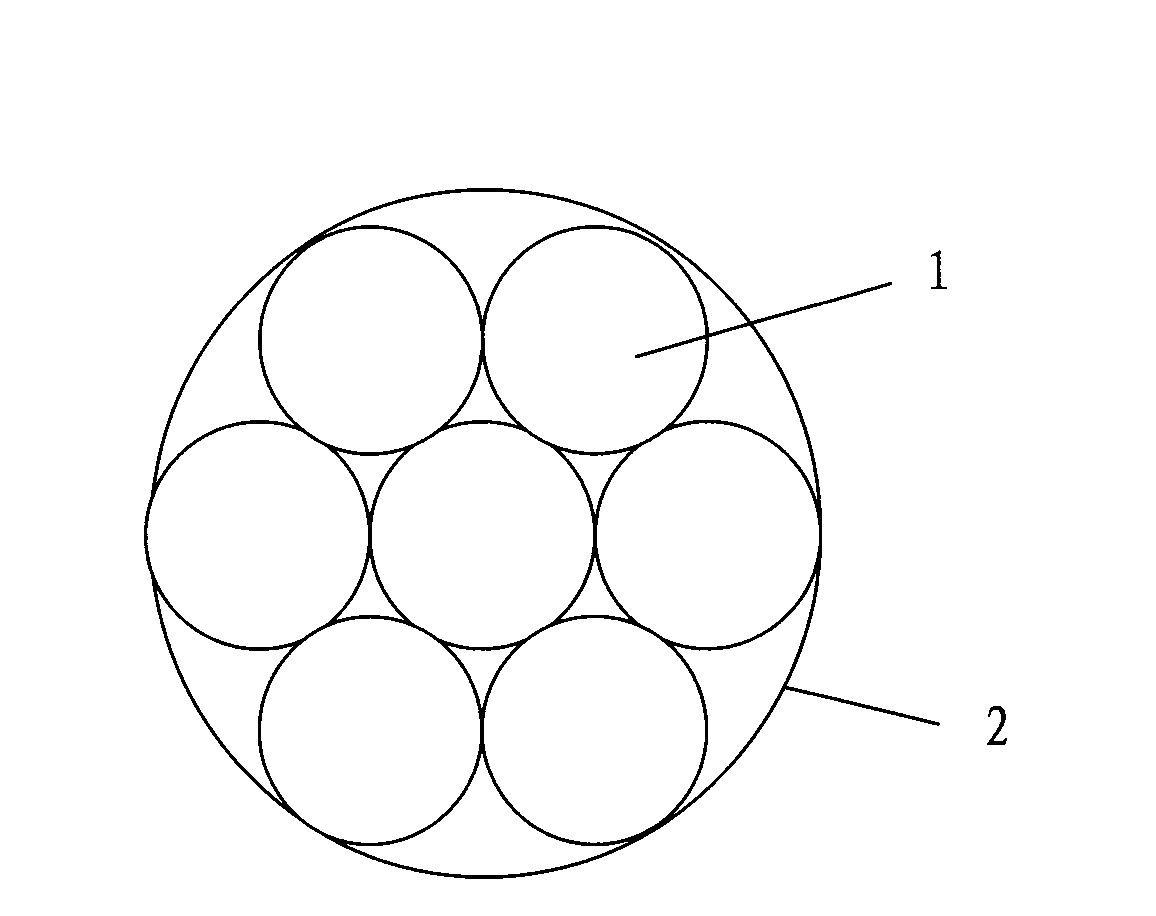

[0042] In this embodiment, a plurality of aluminum alloy 2A01 narrow-diameter thin-walled pipes with a structural size of Φ3×0.2mm, that is, the aluminum alloy tube blank 1, is cold-worked to Φ2×0.2mm. Since the outer diameter of the aluminum alloy tube blank 1 needs to be drawn The drawing process is processed to less than 3mm, so the method of inserting multiple aluminum alloy tube blanks 1 to be drawn into an aluminum alloy cladding tube 2 of the same material at the same time for overall drawing is adopted, and the multiple to be drawn The drawn aluminum alloy tube blank 1 fills the entire interior of the aluminum alloy cladding tube 2 and is combined into a whole, and then the aluminum alloy cladding tube 2 is drawn by using a drawing device. At the same time, the plurality of aluminum alloy tube blanks 1 to be drawn are symmetrically arranged with the central axis of the aluminum alloy cladding tube 2 as the center of symmetry. In this embodiment, the inner diameter of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com