Pallet board/blank for novel strengthened solid wood multi-layer floor and manufacture method thereof

A production method and technology of floor slabs, applied in the direction of chemical instruments and methods, layered products, wood layered products, etc., can solve problems such as high cost, cumbersome surface technology, indoor environmental pollution, etc., and achieve color fastness and gloss Satisfactory, promising application prospects, simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

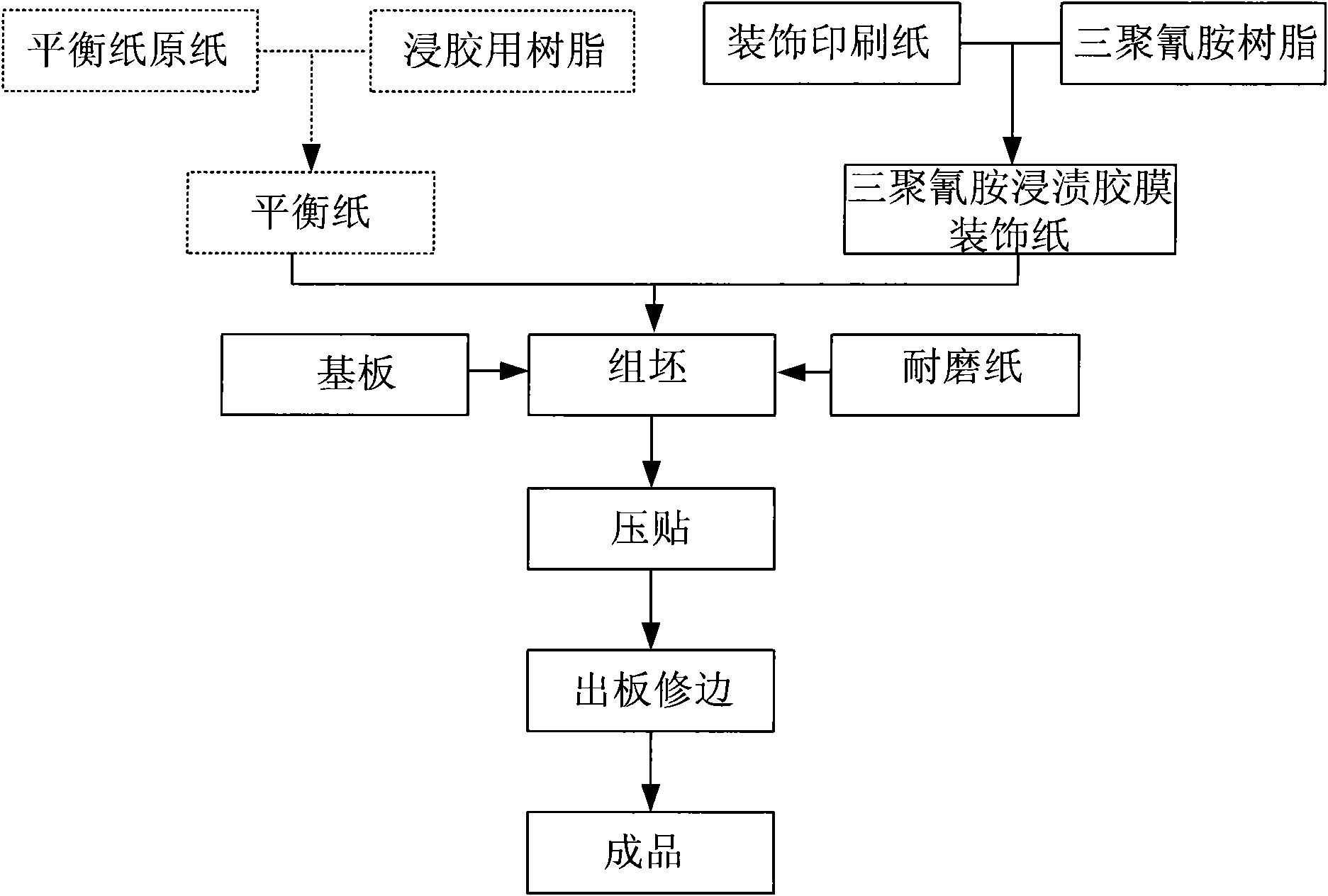

Method used

Image

Examples

Embodiment 1

[0027] Assemble the steel plate and buffer pad into the laminating machine, select a three-layer plywood as the substrate, wipe off dust, sawdust, etc. on the surface, and cover the balance paper, melamine-impregnated film decorative paper, and wear-resistant paper in sequence On the plywood, make the balance paper, melamine-impregnated film decorative paper and wear-resistant paper basically overlap to ensure that the balance paper, melamine-impregnated film decorative paper, and wear-resistant paper all cover the surface of the plywood. Plywood impregnated with melamine film decorative paper and wear-resistant paper is sent into the press machine, and the centerline of the plywood is coincident with the centerline of the press; close the press and start pressing. The pressing time is 30 minutes and the hot pressing temperature is 90°C. , hot pressing pressure 200kg / cm 2 , and then take it out from between the upper and lower templates of the hot press, and the operator cuts ...

Embodiment 2

[0029] Assemble the steel plate and buffer pad into the laminating machine, select four-layer plywood as the substrate, wipe off dust, sawdust, etc. on the surface, and cover the balance paper, melamine-impregnated film decorative paper, and wear-resistant paper in sequence On the plywood, make the balance paper, melamine-impregnated film decorative paper and wear-resistant paper basically overlap to ensure that the balance paper, melamine-impregnated film decorative paper, and wear-resistant paper all cover the surface of the plywood. The plywood impregnated with melamine film decorative paper and wear-resistant paper is sent into the press machine, and the centerline of the plywood is coincident with the centerline of the press machine; close the press machine and start pressing, the pressing time is 18 seconds, and the hot pressing temperature is 200°C , hot pressing pressure 600kg / cm 2 , and then take it out from between the upper and lower templates of the hot press, and ...

Embodiment 3

[0031] Assemble the steel plate and buffer pad into the laminating machine, select the five-layer plywood as the substrate, wipe off the dust, sawdust, etc. on the surface, cover the balance paper, melamine-impregnated film decorative paper, and wear-resistant paper in sequence On the plywood, make the balance paper, melamine-impregnated film decorative paper and wear-resistant paper basically overlap to ensure that the balance paper, melamine-impregnated film decorative paper, and wear-resistant paper all cover the surface of the plywood. The plywood impregnated with melamine film decorative paper and wear-resistant paper is sent into the press machine, and the centerline of the plywood is coincident with the centerline of the press machine; close the press machine and start pressing, the pressing time is 10 minutes, and the hot pressing temperature is 150°C , hot pressing pressure 400kg / cm 2 , and then take it out from between the upper and lower templates of the hot press, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com