Method and device for generating power by utilizing waste gas of matrix-type charcoal kiln

A matrix-type exhaust gas technology, applied in gas turbine devices, gaseous engine fuels, waste heat treatment, etc., can solve problems such as waste of resources, achieve the effects of reducing harmful substances, facilitating collection and utilization, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention will be further described below in conjunction with the accompanying drawings and embodiments.

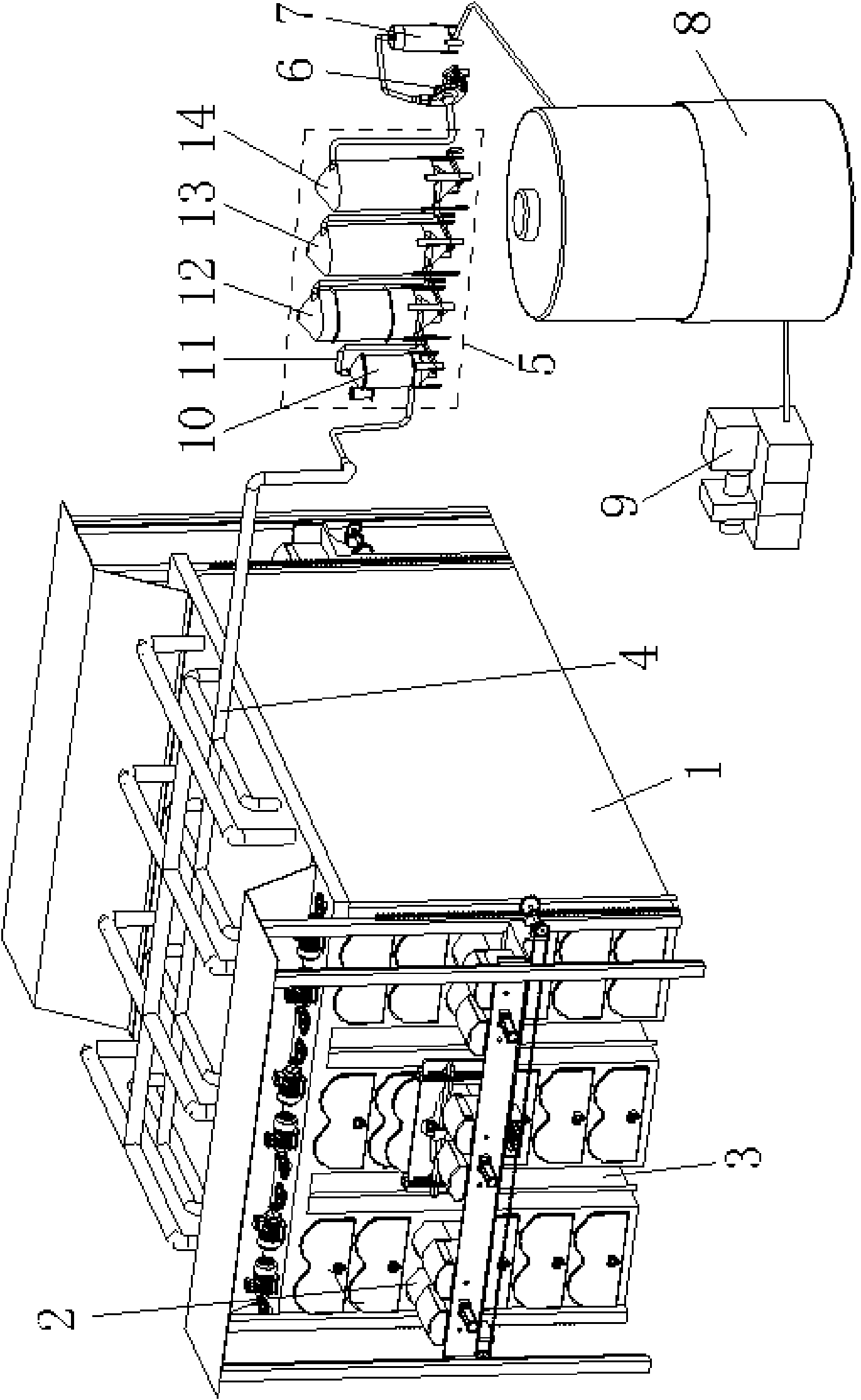

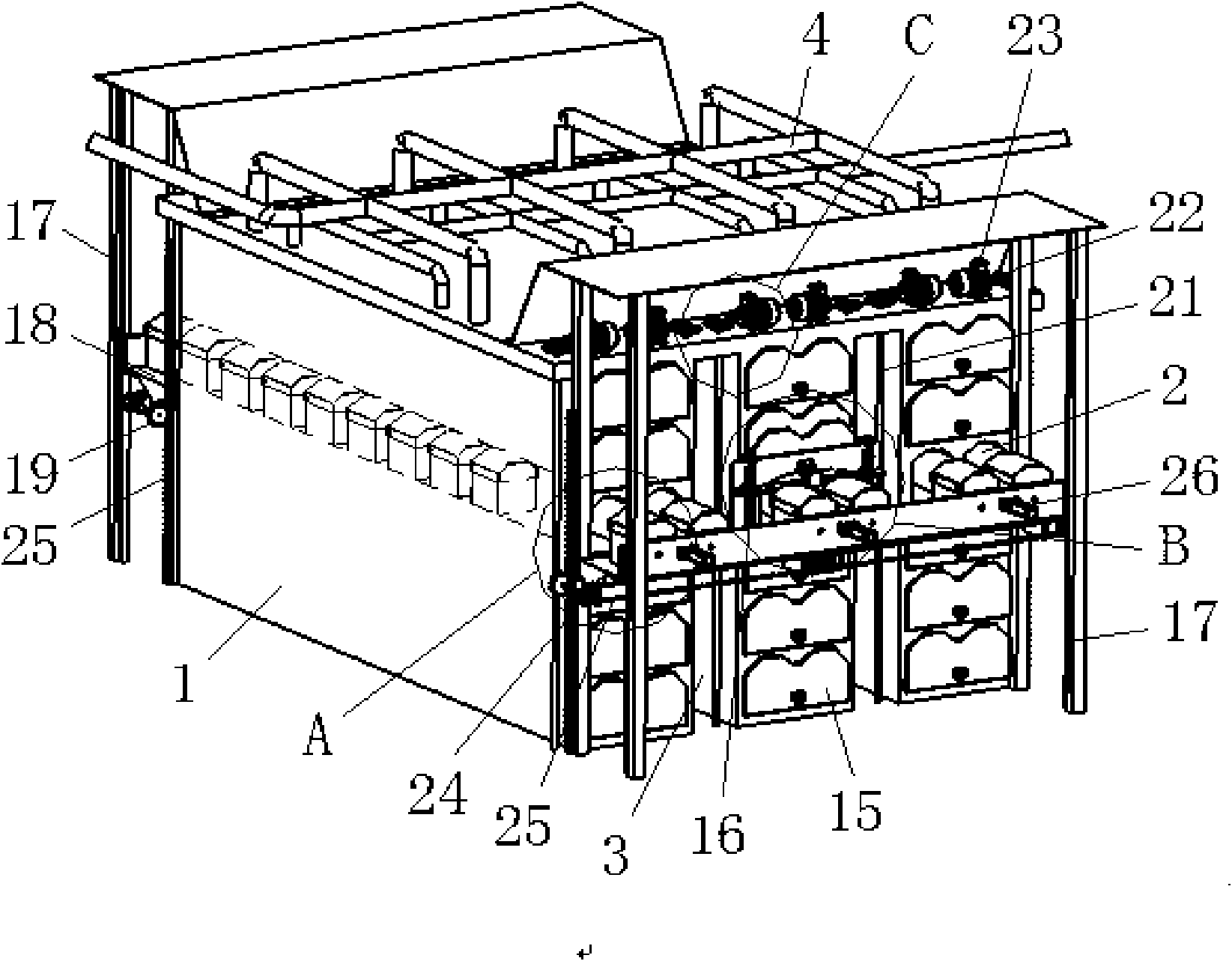

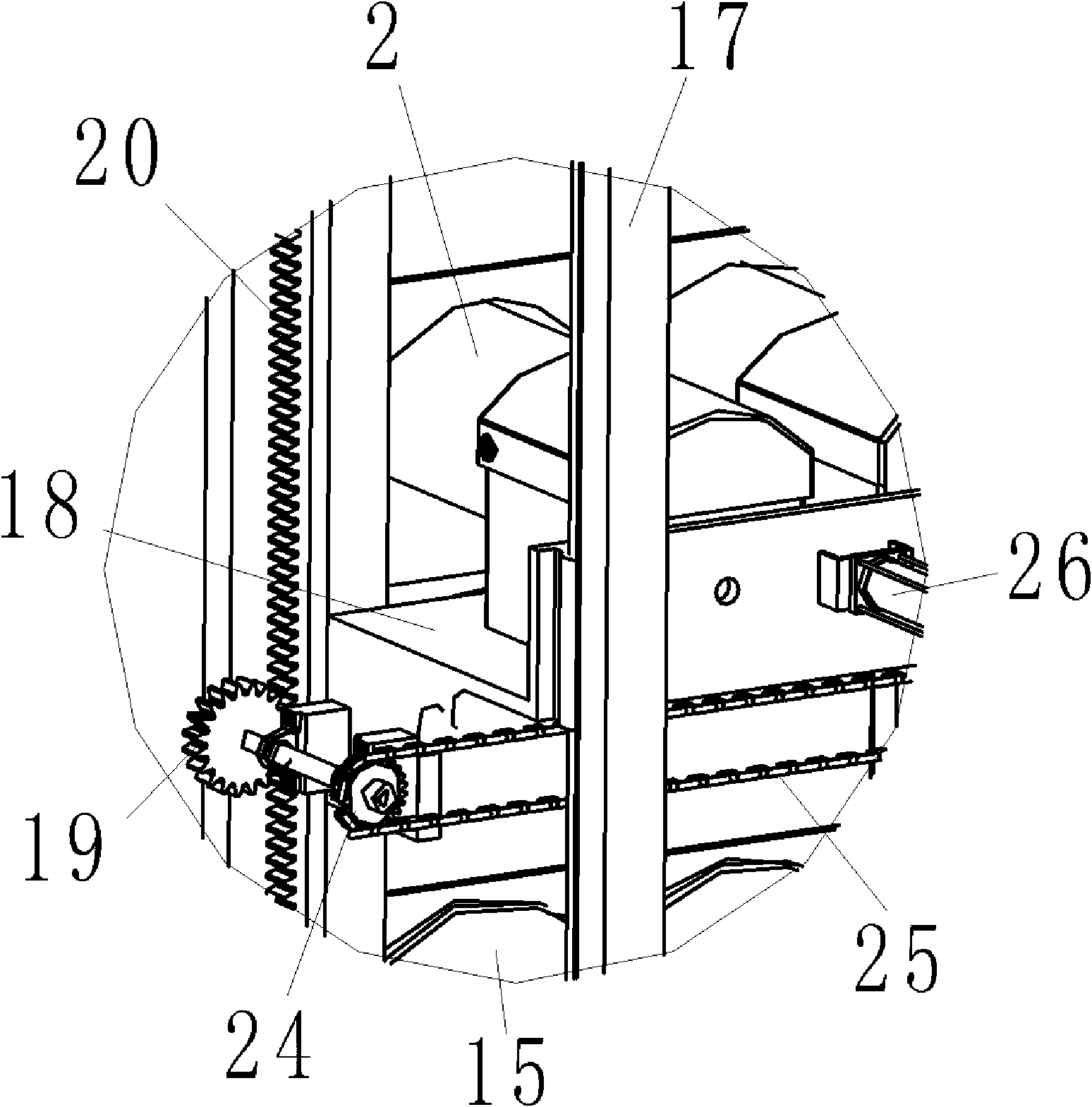

[0024] Examples of inventions are figure 1 As shown: the method of using matrix charcoal kiln exhaust gas to generate electricity is: adopt a three-dimensional kiln body 1, the kiln body is made of refractory materials, and arrange in the kiln body a channel group arranged in a matrix with two columns and more than two layers, and the row It can be multiple rows of at least two layers, and the column can be multiple columns of at least two columns. More than one kiln car channel 2 is set in each channel group; the kiln car can be moved to the designated kiln car channel by setting at the front of the channel group The entrance lifting and moving device inside; it is used to lift the kiln car to different layers, and move laterally to the corresponding kiln car channel 2 entrance, and push the kiln car into the kiln car channel 2 to burn charcoal; at the rear of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com