Double-sided bonding long-wavelength vertical cavity surface emitting laser and manufacturing method thereof

A vertical cavity surface emission, laser technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of difficult to achieve high reflectivity, difficult epitaxial growth, large thermal resistance, etc., to avoid secondary epitaxy process, The effect of reducing the difficulty of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to specific embodiments and accompanying drawings.

[0044] Please see attached Figure 1 to Figure 13 . The purpose of the present invention is to provide a double-sided bonding long-wavelength vertical cavity surface emitting laser.

[0045] The structure of the laser is as follows:

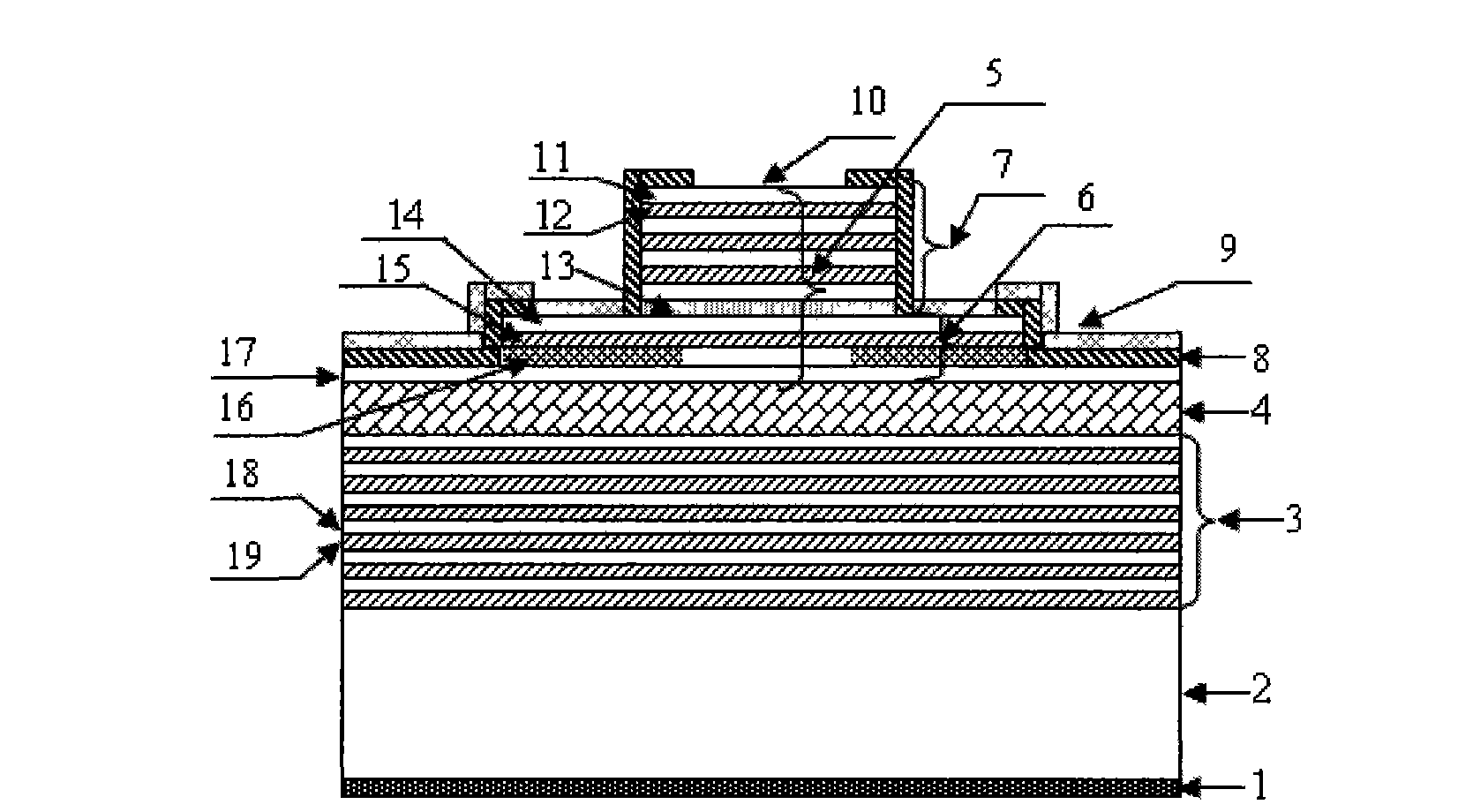

[0046] figure 1 It is a schematic diagram of the double-sided bonding long-wavelength surface emitting laser of the present invention. The laser includes an N-type electrode 1, the N-type electrode is fabricated on the back of an N-type GaAs substrate 2, the N-type GaAs substrate 2, and the N-type GaAs / / Al 0.9 Ga 0.1 As AlGaAs distributed Bragg reflector DBR3, N-type DBR is fabricated on N-type GaAs substrate 2, including 32 periods of N-type GaAs / Al 0.9 Ga 0.1 The As layers 18 and 19 are composed of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com