Preparation method of polyethylene hollow fiber membrane with aperture in gradient distribution

A technology of gradient distribution and polyethylene, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of large flux, low retention efficiency, high porosity, high flux, etc., and achieve good retention effect , high porosity, good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

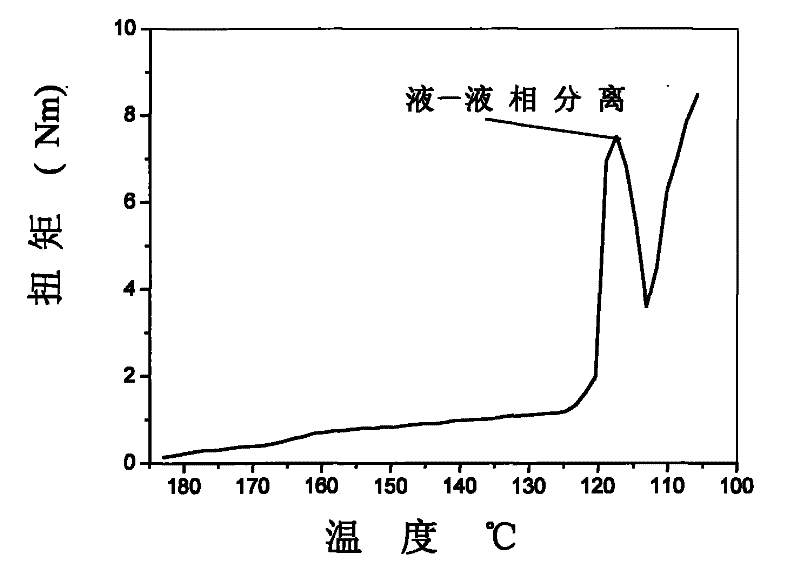

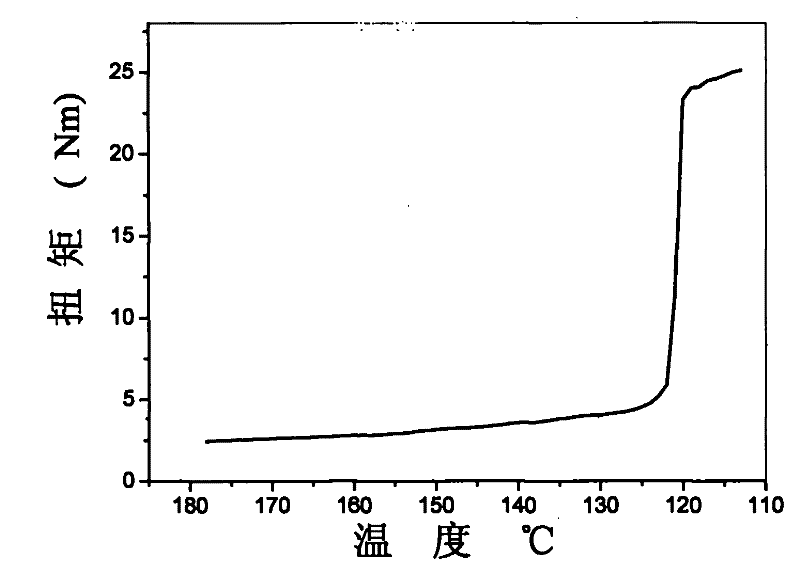

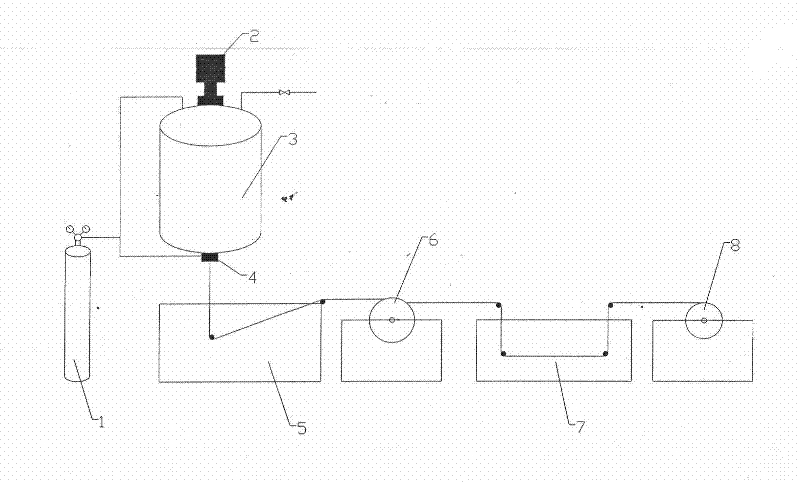

Embodiment 1

[0069] With 30wt% high-density polyethylene (Qilu Petrochemical J7000), 70wt% di-n-octyl phthalate, 0.5wt% 2,6-di-tert-butyl p-cresol antioxidant additive (based on high-density polyethylene and The total weight of di-n-octyl phthalate), melted at 185°C to form a homogeneous solution, controlled pressure 0.20MPa, extruded the homogeneous solution through a self-made spinning machine at 145°C to obtain hollow filaments, and the spinneret The type of spinneret normally used for the production of hollow fibers is used. The hollow spinneret is a sleeve-type spinneret with an air supply pipe inside, and the central air supply pipe is fed with nitrogen at a pressure of 20 cm water column, and the nitrogen temperature is 80 ° C after being heated by the homogeneous solution. The hollow fiber first passes through a 10cm air gap, the air temperature is 35°C, and then quenched in a 50°C water bath to separate the phases and solidify the hollow fiber into shape. Soak the hollow filament...

Embodiment 2

[0071] The same method as in Example 1 was followed except that a continuous stretching process was added before the extraction process. The stretching temperature was 50°C, and the stretching ratio was 125%. The performance of the membrane is shown in Table 1, and the gas flux and pore size are significantly improved.

Embodiment 3

[0073] The same method as in Example 1 was followed except that a continuous stretching process was added before the extraction process. The stretching temperature was 50°C, and the stretching ratio was 145%. The properties of the membrane are shown in Table 1. The obtained hollow fiber membrane has very high gas flux, large pore size and porosity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com