High-efficiency insulating material used for high-temperature pipeline and preparation method thereof

A technology of thermal insulation materials and pipelines, which is used in pipeline protection, heat exchange equipment, pipeline protection through thermal insulation, etc., to achieve the effect of reducing the proportion of solid heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

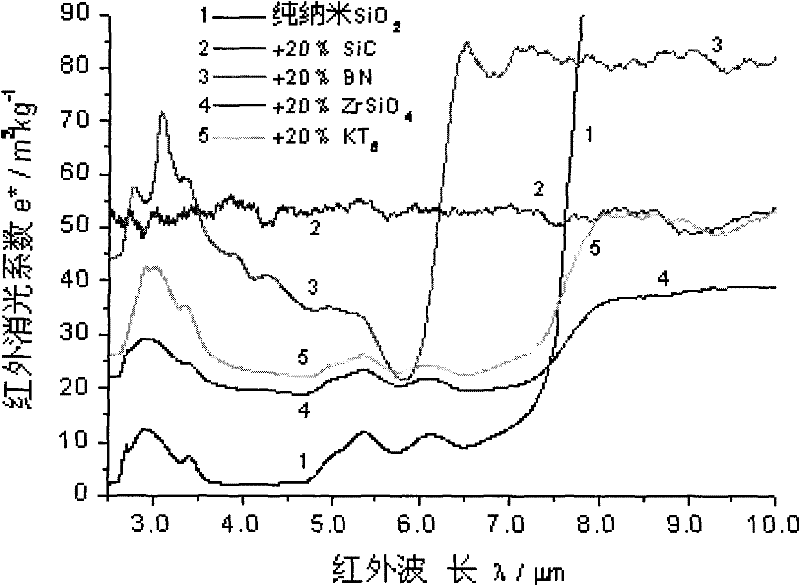

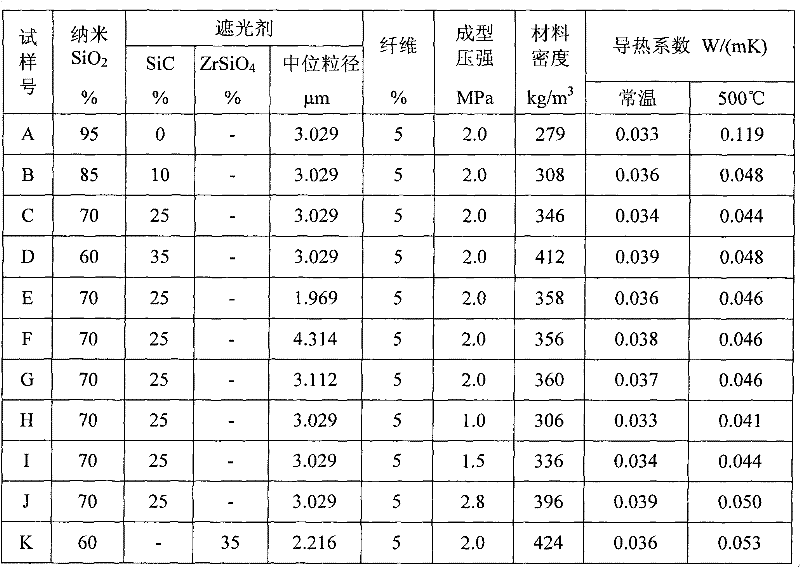

Embodiment 1

[0033] Using a specific surface area of 200m 2 / g nano-SiO 2 60wt% of powder, 35wt% of zircon powder with a particle size range of 0.39-13.98μm and a median particle size of 2.216μm, 5wt% of alkali-free ultrafine glass fibers with a diameter of 1-10μm and a length of 1-5mm, at a speed of 2400rpm Blend on high speed mixer for 5 minutes. Placed in a steel mold of 210×110×75mm, and dry-pressed under a pressure of 2MPa to form a sample with a thickness of about 30mm (sample K in Table 2). The molded body is elastic when pressed, and its bulk density is measured to be 424kg / m 3 , The thermal conductivity at room temperature is 0.036W / (m·K), and the average thermal conductivity at 500°C is 0.053W / (m·K). nano-SiO2 After adding zircon into the matrix, the high temperature thermal conductivity is reduced to half of that of sample A without opacifying agent in the comparative example. Its thermal conductivity at 500°C is less than that of still air at 500°C.

Embodiment 2

[0035] The zircon powder was replaced by SiC powder with a particle size range of 1.29-5.97 μm and a median particle size of 3.029 μm, and the others remained unchanged. The molded body (sample D in Table 2) is elastic when pressed, and its bulk density is measured to be 412kg / m 3 , the thermal conductivity at room temperature is 0.039W / (m·K), and the average thermal conductivity at 500°C is 0.048W / (m·K). Its thermal conductivity at 500°C is less than that of still air at 500°C.

[0036] Table 2 Nano-SiO 2 / Opacifier / Fiber composite material thermal conductivity measurement results

[0037] (Shanghai Institute of Ceramics, Chinese Academy of Sciences)

[0038]

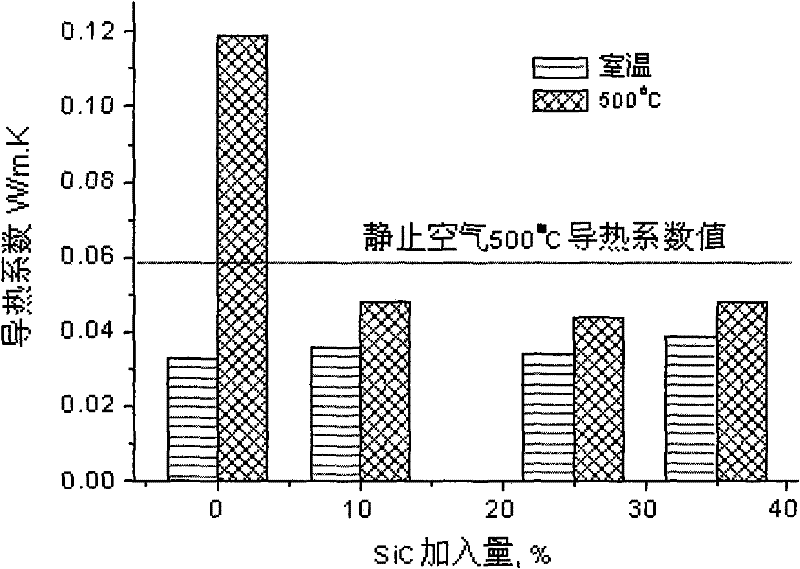

Embodiment 3

[0040] In the comparative example, 10wt%, 25wt%, and 35wt% of SiC powder with a particle size range of 1.29-5.97μm and a median particle size of 3.029μm were added respectively, and the same fiber 5wt% was kept, and the specific surface area was adjusted to 200m 2 / g nano-SiO 2 The amount of powder added to the total amount is 100%. Mix for 5 minutes in a high-speed mixer with a rotation speed of 2400 rpm. Placed in a steel mold of 210×110×75mm, and dry-pressed under a pressure of 2MPa to form a sample with a thickness of about 30mm. The molded body is elastic when pressed, and its properties are measured as follows:

[0041] Sample B-10wt% SiC addition, bulk density 308kg / m 3 , the thermal conductivity at room temperature is 0.036W / (m K), and the average thermal conductivity at 500°C is 0.048W / (m K);

[0042] Sample C-25wt% SiC addition, bulk density 346kg / m 3 , the thermal conductivity at room temperature is 0.034W / (m K), and the average thermal conductivity at 500°C is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com