Preparation method of inorganic nanometer materials and polythiophene derivant composite materials

A technology of inorganic nanomaterials and polythiophene derivatives, applied in the field of composite materials and preparations of inorganic nanomaterials and polythiophene derivatives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

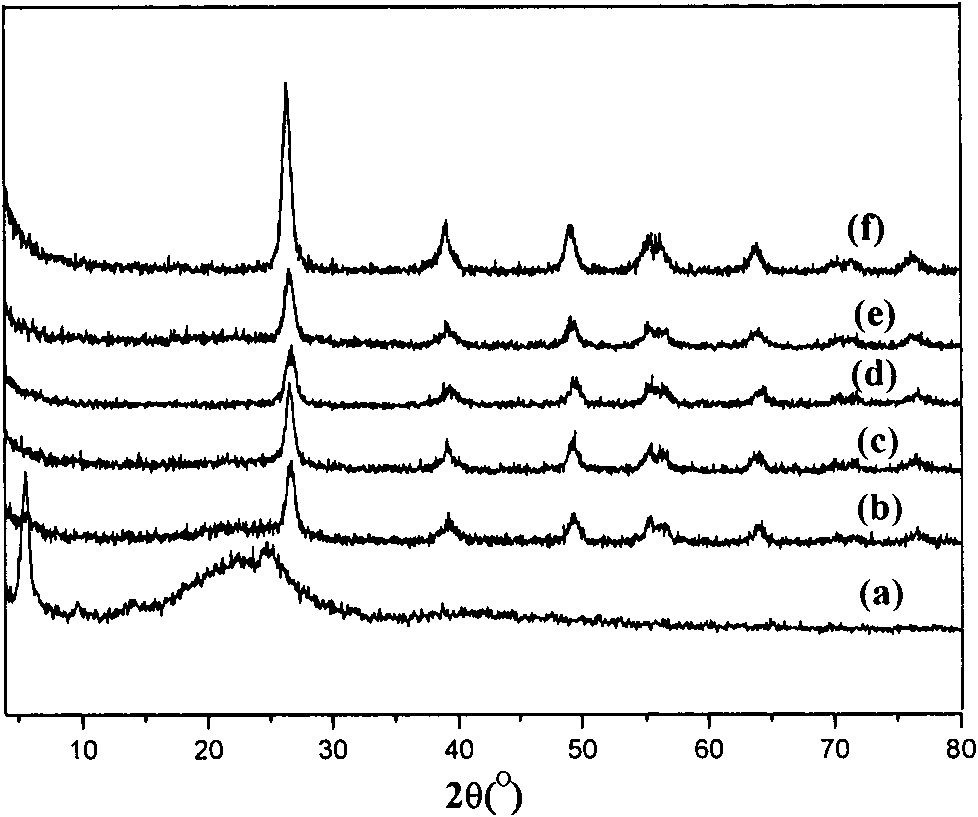

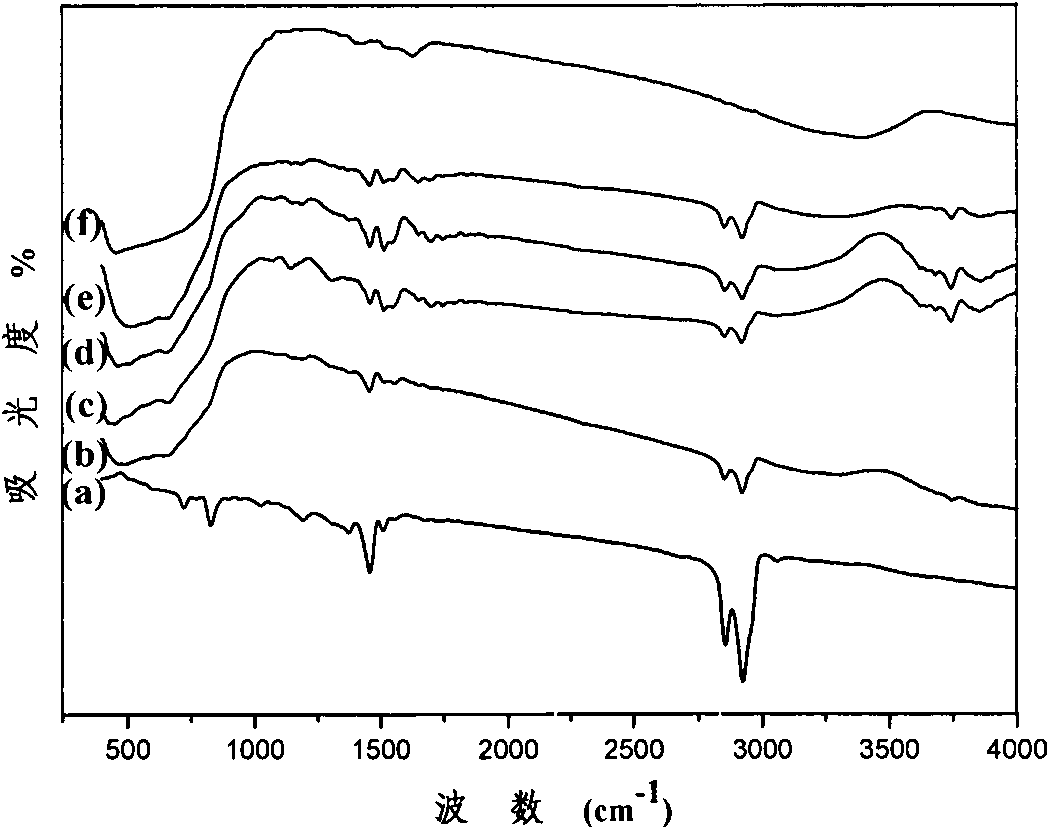

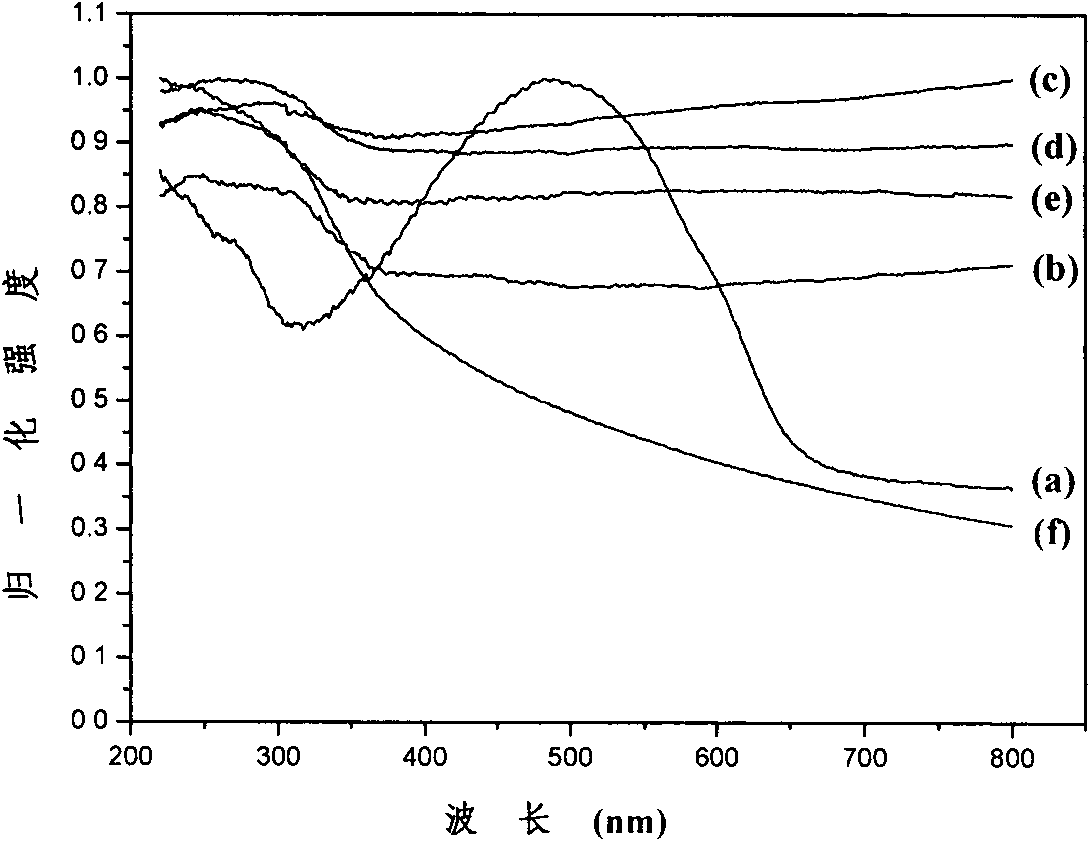

[0046] Embodiment 1: Nano TiO 2 - Preparation of poly-3-octylthiophene composites

[0047] A. In a glass bottle with a sealed cover, dissolve 1.2g, 0.6g, 0.3g, 0.2g of POT in 30mL, 15mL, 7.5mL, 5mL of chloroform to make a saturated solution, and then make the average particle size 8nm TiO 2 According to POT / TiO 2 Mass ratios of 2:1, 1:1, 1:2, 1:3 are added to the above saturated solution;

[0048] B. Add anhydrous FeCl dropwise according to 4 times the amount of POT material after sealing 3 into the above solution, and stop stirring at room temperature for 8 hours; the resulting mixture is vacuum-removed to remove the solvent, and after drying, POT / TiO 2 Composite materials with mass ratios of 2:1, 1:1, 1:2, and 1:3, respectively.

Embodiment 2

[0049] Embodiment 2: Preparation of nano ZnO-poly 3-octylthiophene composite material

[0050] In a glass bottle with a sealed cover, dissolve 0.2g of 3-octylthiophene in 5mL of chloroform, then add 1g of ZnO with an average particle diameter of 10nm into the solution, seal it and add dropwise to 4% of the amount of monomeric substances. times anhydrous FeCl 3 , Stirring at 0 C for 3 h and then stopping; the resulting mixture was vacuum-removed to remove the solvent, and dried to obtain a nano-ZnO-poly-3-octylthiophene composite material with a mass ratio of 1:5.

Embodiment 3

[0051] Example 3: Preparation of nano ZnO-poly 3-decylthiophene composite material

[0052] In a glass bottle with a sealed cover, dissolve 0.2g of 3-decylthiophene in 5mL of chloroform, then put 1g of ZnO with an average particle size of 10nm into the solution, seal it and add dropwise the amount of monomeric substance 4 times the amount of anhydrous FeCl 3 , Stirring at 10° C. for 12 h and then stopping; the resulting mixture was vacuum-removed to remove the solvent, and dried to obtain a nano-ZnO-poly-3-decylthiophene composite material with a mass ratio of 1:5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com