Method for preparing electronic-grade high-purity stannous methanesulfonate solution

The technology of pure stannous methanesulfonate and stannous methanesulfonate is applied in the field of preparation of electronic-grade high-purity stannous methanesulfonate solution, which can solve the problems of long operation cycle, difficult handling, and difficult product quality requirements. , to achieve the effect of less environmental pollution, low cost and complete crystal form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

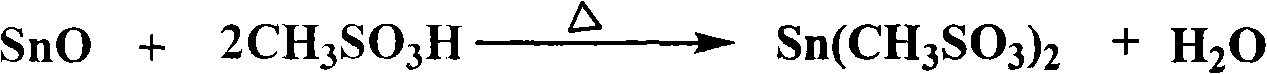

Method used

Image

Examples

Embodiment 1

[0021] (1) Take methanesulfonic acid (purity 99.9%) and stannous oxide with a molar ratio of 3:1 and place them in a container, heat up to 100°C, and react for 4h under stirring conditions with a rotating speed of 100r / min, and wait for oxidation End reaction after stannous dissolving completely, obtain reaction solution;

[0022] (2) Cool and crystallize the reaction solution, filter to obtain a filter cake; wash the filter cake with anhydrous ether, and vacuum-dry it at 85°C to obtain a white solid stannous methanesulfonate; after testing, the methanesulfonate The purity of stannous acid is 99.9% by mass percentage, and the content of metal impurities Fe, Pb, Zn, Cu, Co, Cd, Mn is all≤5ppm;

[0023] (3) Add stannous methanesulfonate to deionized water to prepare a stannous methanesulfonate solution that is 300 g / L with stannous ion mass volume ratio concentration.

Embodiment 2

[0025] (1) Take methanesulfonic acid (purity 80%) and stannous oxide with a molar ratio of 6:1 and place them in a container, heat up to 130°C, and react for 6h under stirring conditions with a rotating speed of 200r / min, and wait for oxidation End reaction after stannous dissolving completely, obtain reaction solution;

[0026] (2) Cool and crystallize the reaction solution, filter to obtain a filter cake; wash the filter cake with anhydrous ether, and vacuum-dry it at 80°C to obtain a white solid stannous methanesulfonate; after testing, the methanesulfonate The purity of stannous acid is 99.93% by mass percentage, and the content of metal impurities Fe, Pb, Zn, Cu, Co, Cd, Mn is all≤5ppm;

[0027] (3) Add stannous methanesulfonate to deionized water to prepare a stannous methanesulfonate solution that is 300 g / L with stannous ion mass volume ratio concentration.

Embodiment 3

[0029] (1) Take methanesulfonic acid (purity 90%) and stannous oxide with a molar ratio of 4.5:1 and place them in a container, heat up to 120°C, and react for 5h under stirring conditions with a rotating speed of 150r / min, and wait for oxidation End reaction after stannous dissolving completely, obtain reaction solution;

[0030] (2) Cool and crystallize the reaction solution, filter to obtain a filter cake; wash the filter cake with anhydrous ether, and vacuum-dry it at 82°C to obtain a white solid stannous methanesulfonate; after testing, the methanesulfonate The purity of stannous acid is 99.9% by mass percentage, and the content of metal impurities Fe, Pb, Zn, Cu, Co, Cd, Mn is all≤5ppm;

[0031] (3) Add stannous methanesulfonate to deionized water to prepare a stannous methanesulfonate solution that is 300 g / L with stannous ion mass volume ratio concentration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com